Constant pressure automatic grinding device and method based on fuzzy adaptive force control

A fuzzy self-adaptive and adaptable technology, applied in the direction of self-adaptive control, grinding automatic control device, general control system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A constant force automatic grinding method based on fuzzy adaptive force control, including the following steps:

[0047] 1) Calibrate the coordinates of the workpiece through the position sensor, move the x-axis slowly, when the grinding equipment touches the workpiece, the one-dimensional force sensing equipment will generate a step signal, and detect the step signal and the reading of the servo motor encoder, Calculate the conversion relationship between the coordinates of the kinematic mechanism and the coordinates of the workpiece;

[0048] 2) Read the voltage value of the force sensor at different feed depths, and estimate the stiffness of the motion mechanism and clamping mechanism;

[0049] 3) Model the grinding process, design a fuzzy adaptive controller, and preliminarily estimate the control parameters;

[0050] 4) The algorithm of the fuzzy adaptive controller is programmed through the industrial control host, given a constant speed movement of the y-axis, ...

Embodiment 2

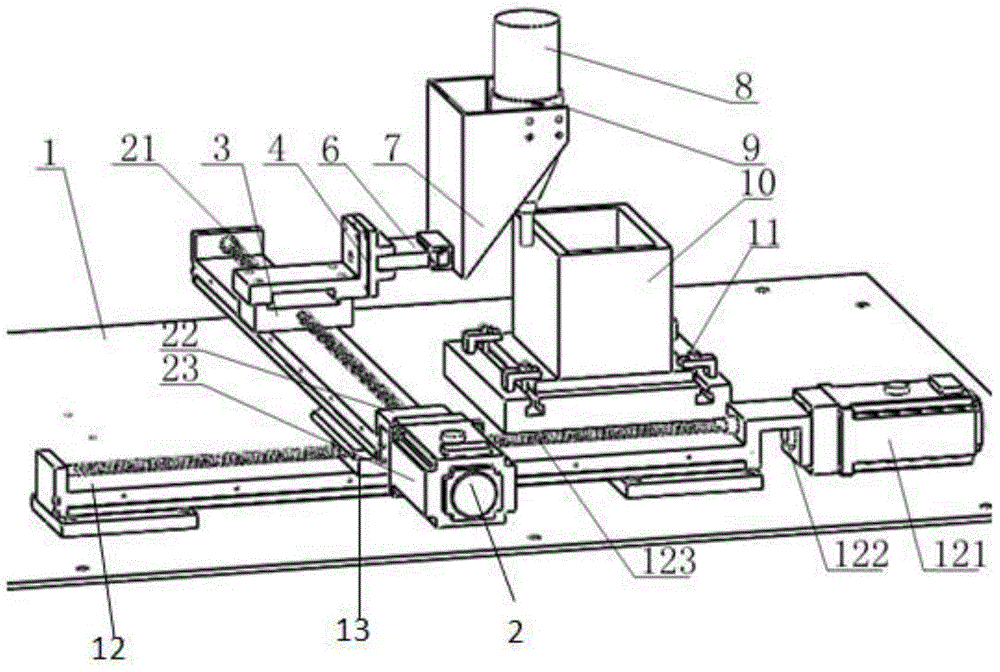

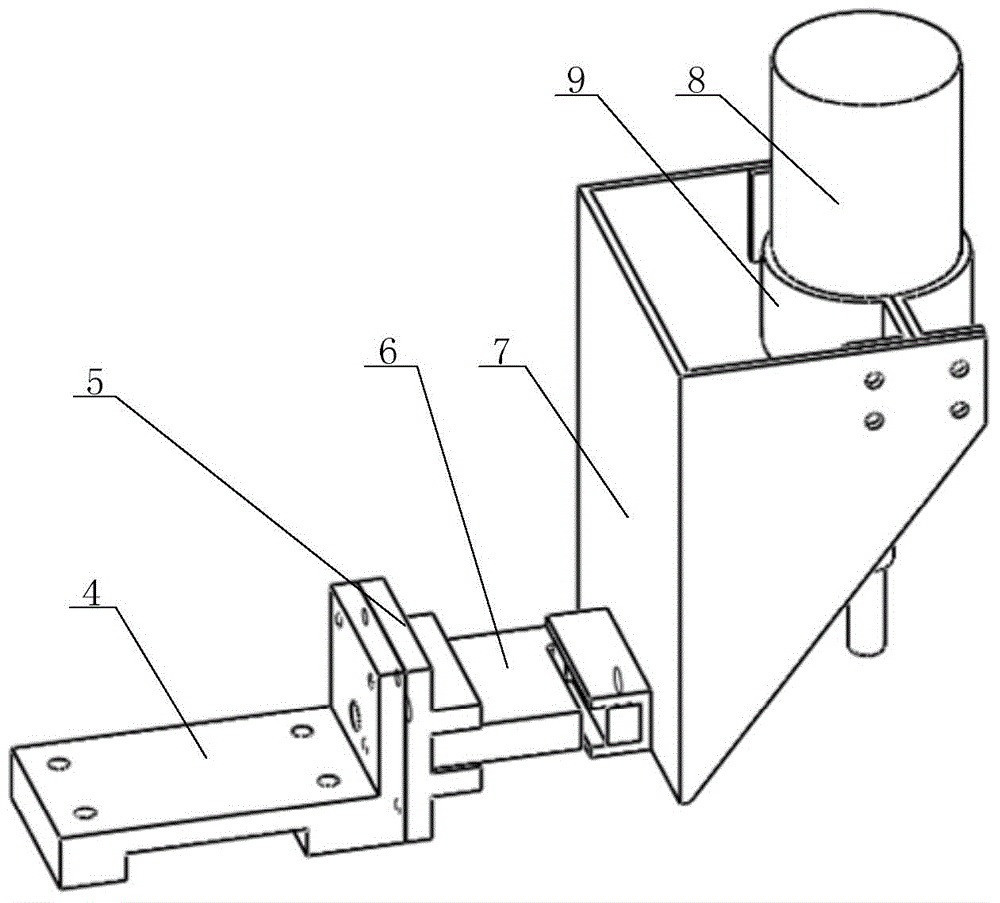

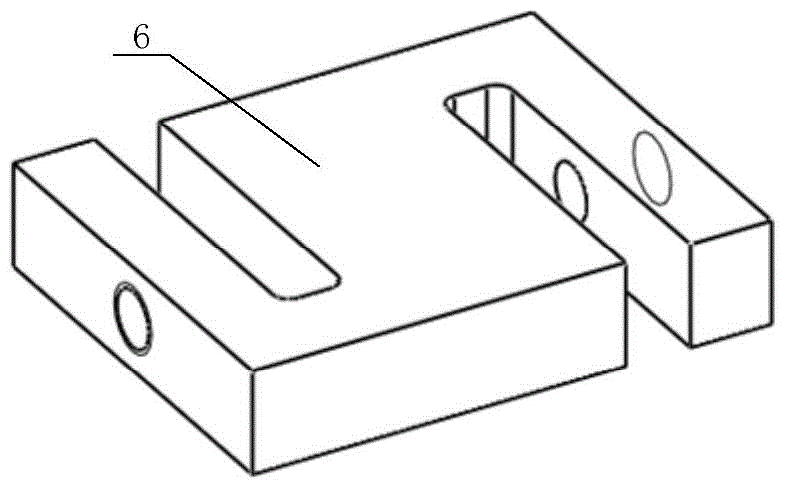

[0071] Such as figure 1 As shown, the grinding device for realizing the constant force automatic grinding method based on fuzzy adaptive force control includes an industrial control host, a workbench 1, a motion mechanism, a one-dimensional force sensing device, and a position sensor for obtaining the position coordinates of the workpiece , grinding equipment and workpiece clamping equipment 11, the motion mechanism and the workpiece clamping equipment are respectively fixed on the workbench, the motion mechanism includes an x-axis direction motion mechanism 12, a y-axis direction motion mechanism 2, and the one-dimensional force One end of the sensing device is connected to the grinding device, and the other end is connected to the y-axis direction movement mechanism 2 of the movement mechanism through the y-axis direction slider 3. The industrial control host is connected with the one-dimensional force sensing device, position sensor, grinding device, The x-axis direction mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com