Preparation method of sulfonic acid type waterborne polyurethane adhesive

A water-based polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems of low solid content, high peel strength, low cohesive strength, etc., and achieve good bonding performance , high peel strength and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 21

[0038] Embodiment 2 uses sodium 1,2-dihydroxy-3-propanesulfonate as a hydrophilic chain extender

Embodiment 2

[0039] Example 2 Put 300g of poly-1,4-butylene adipate (Mn=2000) and 100g of polyoxypropylene glycol (PPG-2000) into a four-necked flask, vacuum dehydrate at 120°C for 2 hours, and cool down to After 70°C, add 100g of acetone for dilution, add 31.5g of IPDI, 11.9g of HDI, 9g of sodium 1,2-dihydroxy-3-propanesulfonate (dissolved in NMP) into a four-neck flask, react at 55°C for 1 hour, and then add trihydroxy 0.3g of methyl propane, 0.1g of dibutyltin dilaurate, react at 60-70°C until the -NCO concentration reaches the theoretical value, then add 150g of acetone to dilute. Pour the prepolymer into the dispersion tank, lower the temperature to 35°C, add 450g of deionized water under high-speed stirring (3000r / min), then add 0.4g of ethylenediamine, and stir at high speed for 20-30min. The water-based polyurethane adhesive is obtained after vacuumizing at 50-60°C to remove the acetone.

[0040] The test results are as follows:

[0041] Solid content: 51.03%.

[0042] Minimum a...

Embodiment 3~5

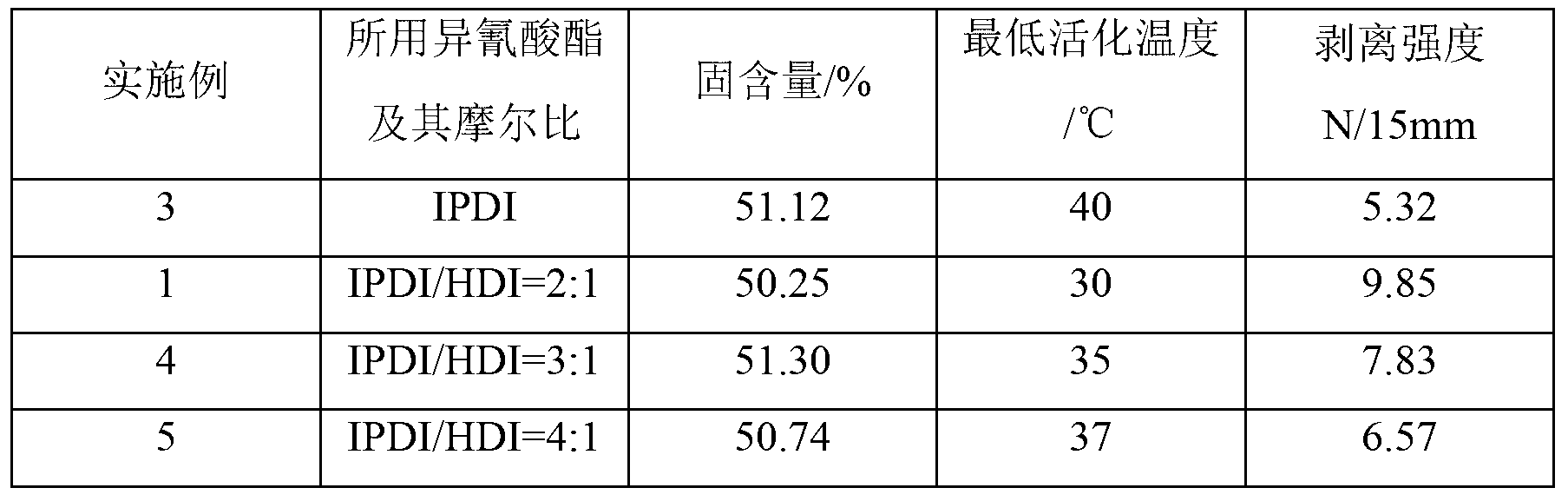

[0045] Operation method is the same as embodiment 1, changes the composition of isocyanate, and concrete formula and result are shown in Table 1:

[0046] Table 1

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com