Oil-resistant and low temperature-resistant thermoplastic elastomer and production method

A production method and elastomer technology, applied in the fields of low-temperature resistant thermoplastic elastomers, wires, oil resistance, cable insulation and sheathing, can solve the problems of large investment and cost, large permanent deformation, high product cost, etc., to save production costs , strong flexural resistance, and the effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

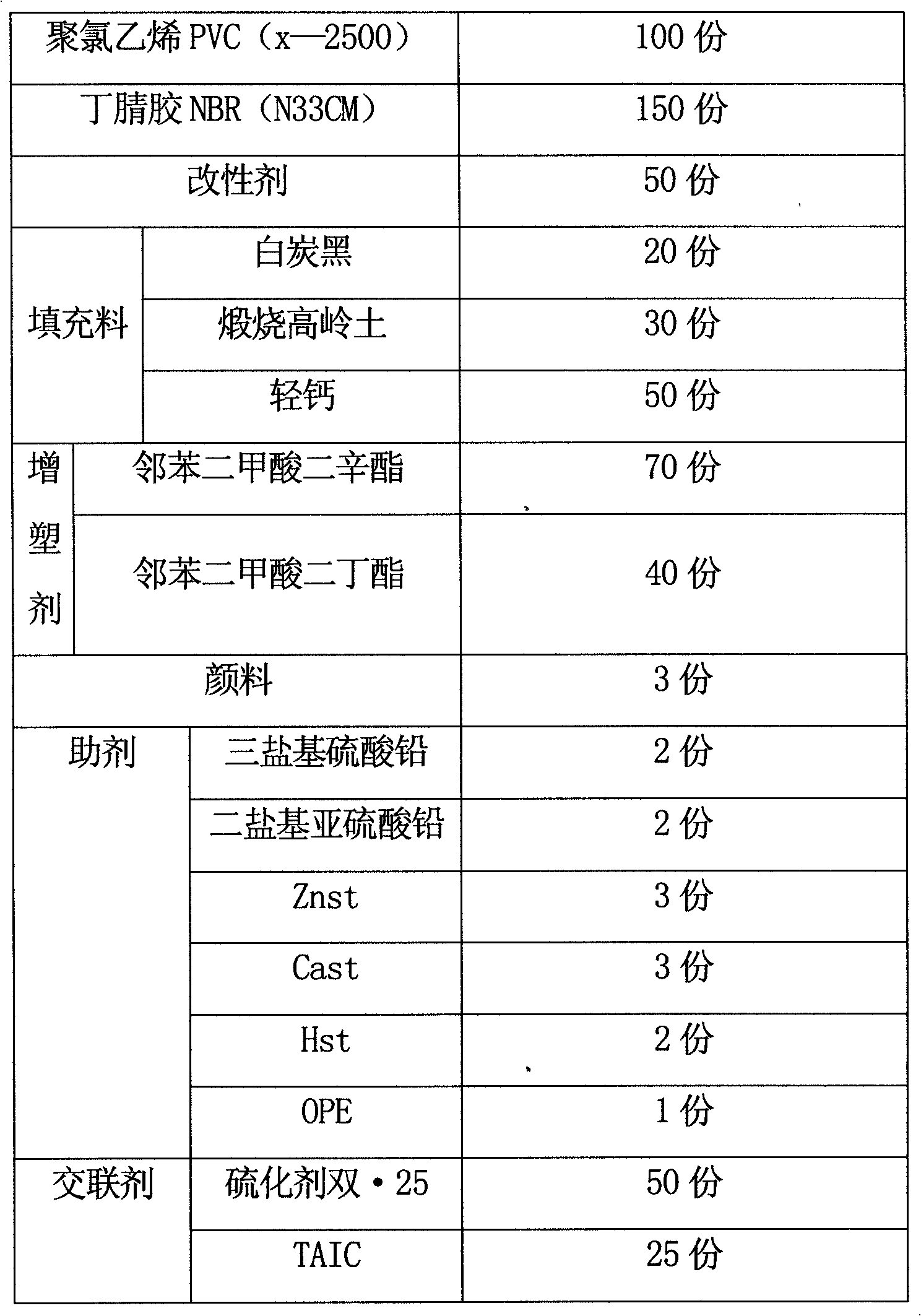

[0024] Components of Example 1:

[0025]

[0026] Preparation method: (1), prepare materials according to weight ratio

[0027] (2) First, add polyvinyl chloride (PVC) to the high-temperature stirring mixer (commonly known as high stirring pot), start the machine, and add plasticizer several times and in small amounts to make the plasticizer fully and evenly absorbed by the PVC resin , With the stirring and oil filling, the temperature of the material continues to rise, and the filling speed of the plasticizer gradually increases. The weight of the plasticizer filled in the resin is 85-90 of the total amount of plasticizer. When the filled plasticizer meets the requirements, all the raw materials and the remaining plasticizer are added to prevent flying dust after the machine is started. Keep clean and hygienic during the production process, and make the materials evenly mixed.

[0028] (3) Add the nitrile butadiene rubber and TPE modifier that have been broken into small pieces be...

Embodiment 2

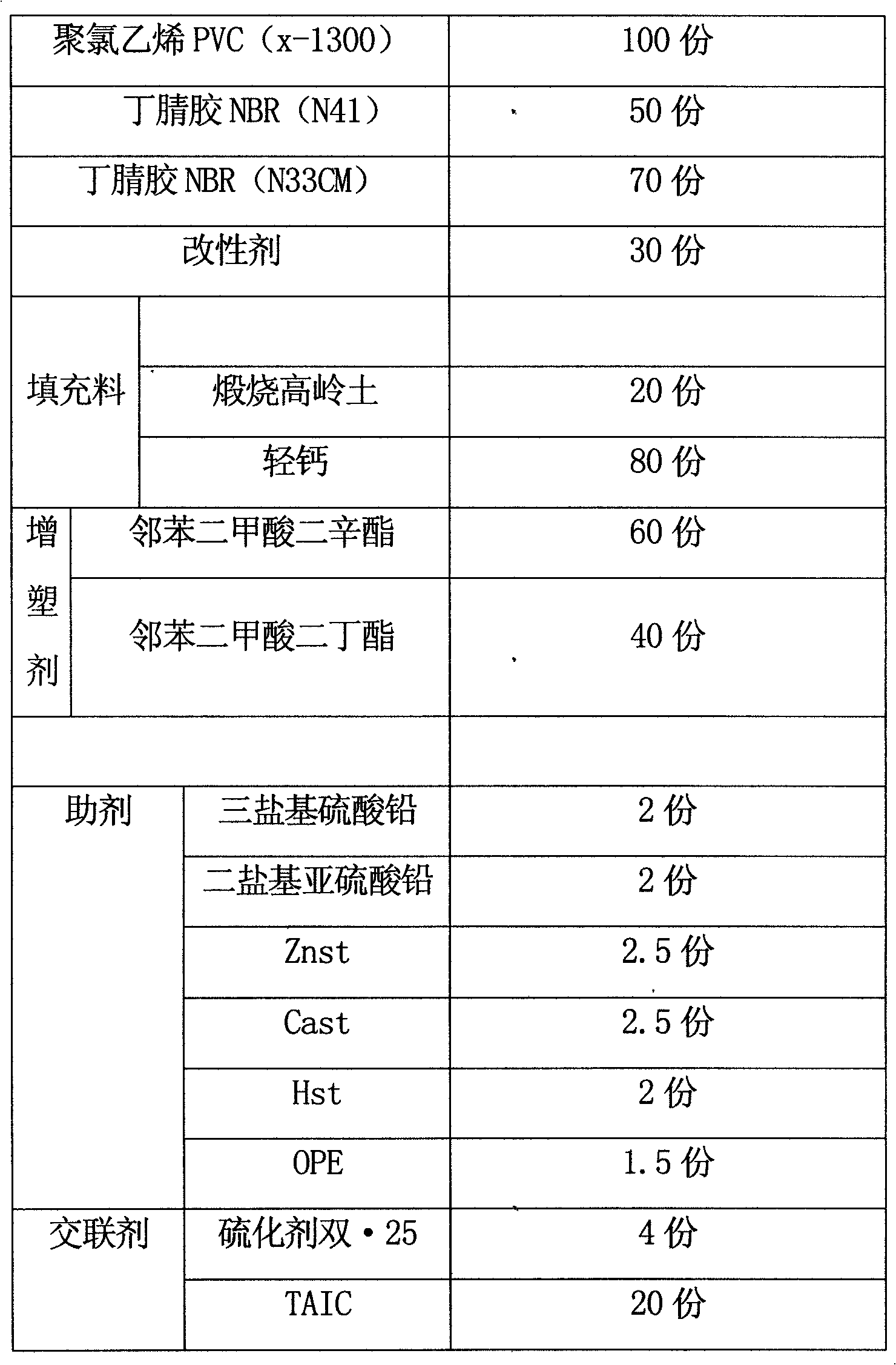

[0037] Example 2 Components:

[0038]

[0039] The preparation method is the same as in Example 1.

Embodiment 3

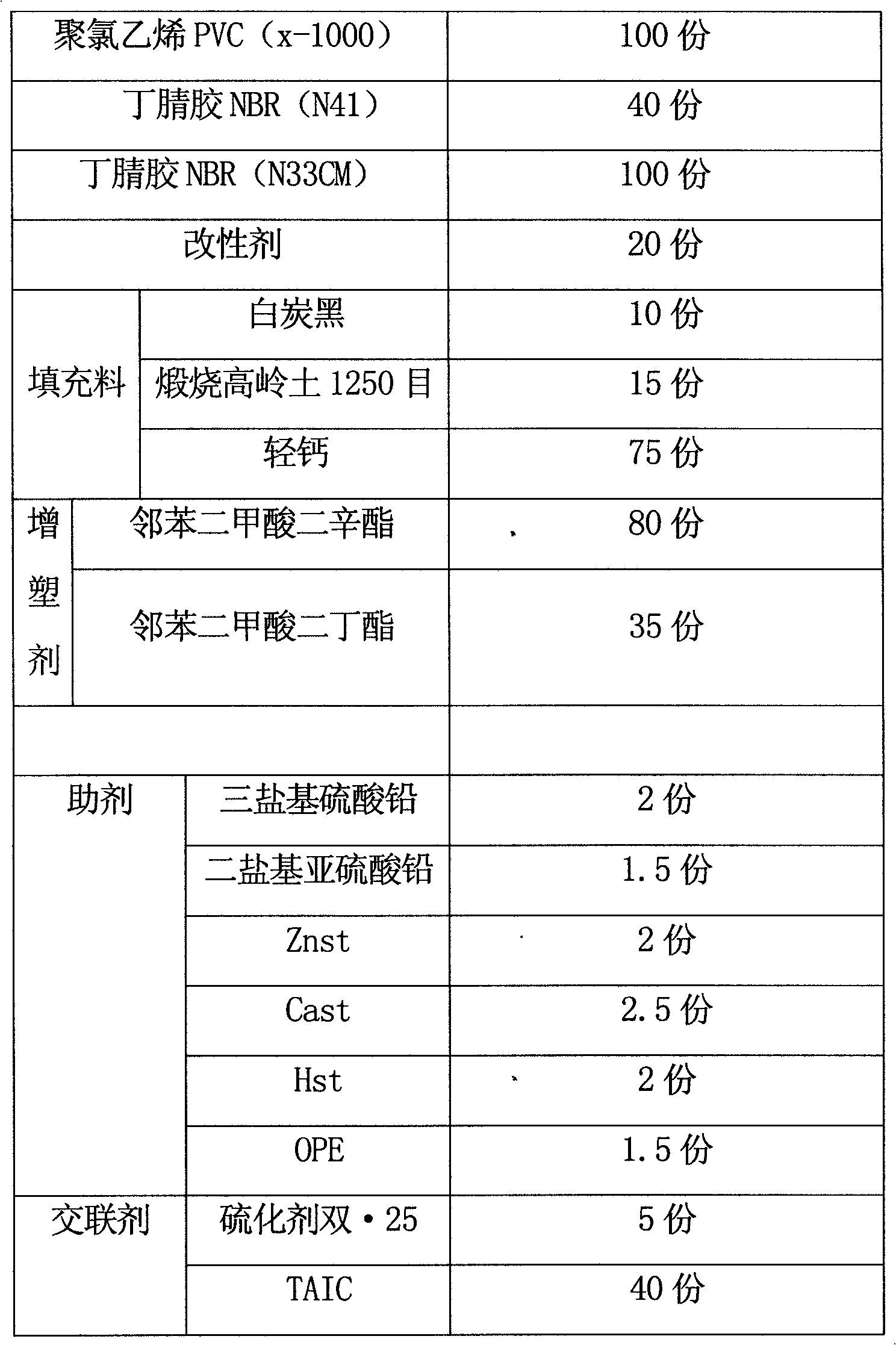

[0040] Example 3 components:

[0041]

[0042] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com