High-speed digital signal transmission cabinet

A high-speed digital signal and transmission cable technology, applied in communication cables, insulated cables, bendable cables, etc., can solve problems such as increasing the effective dielectric constant and increasing the diameter of high-speed digital signal transmission cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

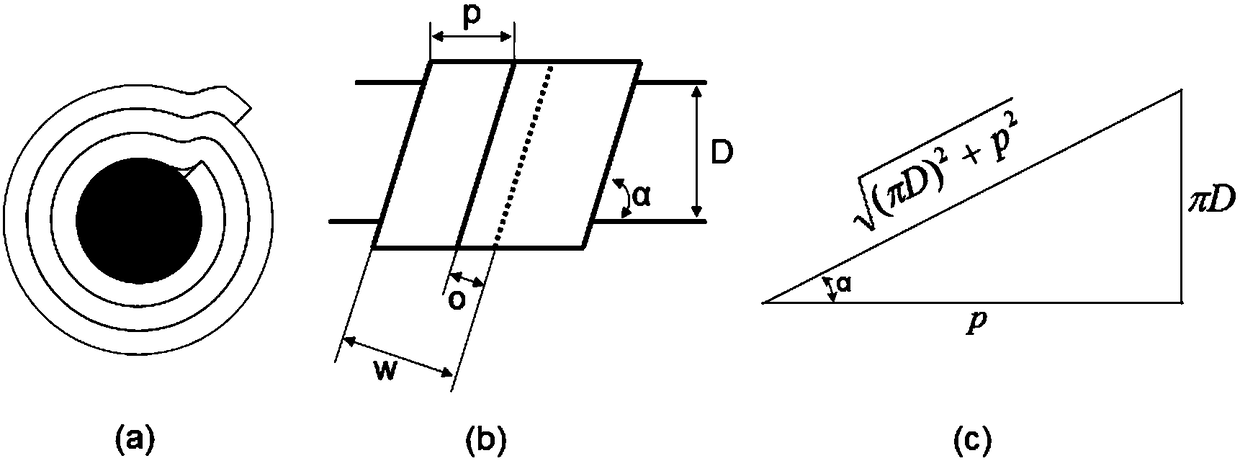

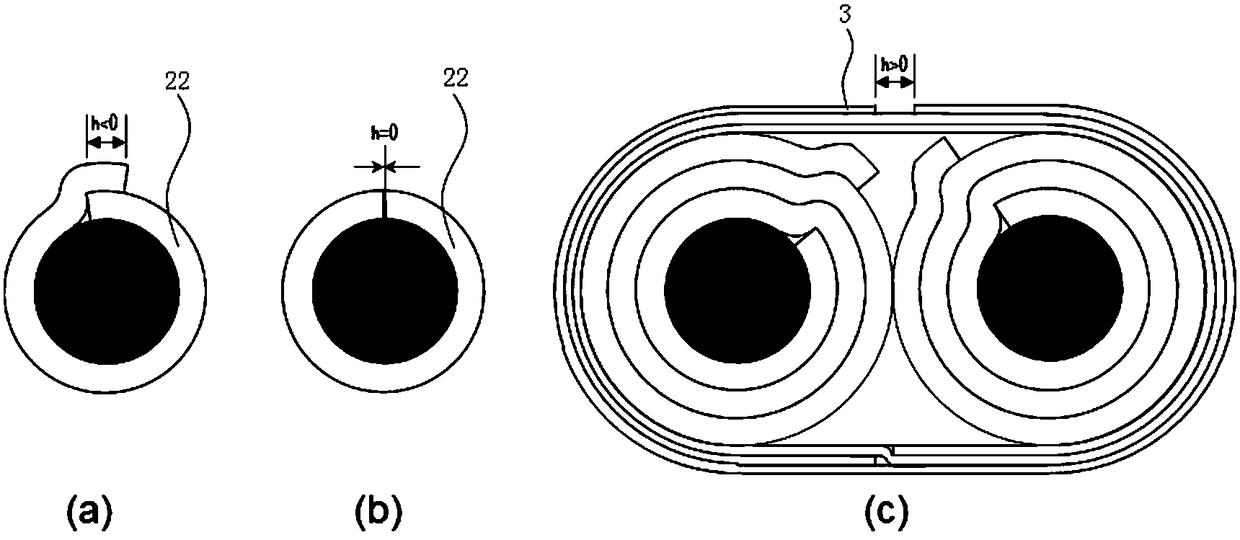

[0152] Figure 6 Represent the structural schematic diagram of the differential signal cable 1A of embodiment 1 of the high-speed digital signal transmission cable of the present invention, wherein Figure 6 (a) is a cross-sectional structure diagram (a view perpendicular to the length direction of the conductor), Figure 6 (b) is a perspective view of the end of the differential signal cable 1A. It can be seen from the figure that the high-speed digital signal transmission cable of the present invention includes a differential signal cable 1A, which is composed of an insulating core wire 2, a shielding layer 3, a first stable layer 5, a second stable layer 6 and an optional drain wire 4.

[0153] The insulated core wire 2 can adopt Figure 4 Any structure of 2A, 2A1, 2A2. The double conductors 211, 212 in the insulated core wire 2 are formed by excellent electrical conductors such as copper, aluminum, iron, steel, or single core wires or stranded wires that are tinned, si...

Embodiment 2

[0169] Figure 11 A schematic diagram showing the structure of a differential signal cable 1B according to Embodiment 2 of the high-speed digital signal transmission cable of the present invention, which is shown as having an insulated core wire 2, a shielding layer 3, a first stable layer 5, a second stable layer 6, a sheath layer 7 and Optional drain line4. Components having common functions to those described in 1A are denoted by the same reference numerals, and their descriptions are omitted.

[0170] When the second stabilizing layer 6 is not thermally fused (such as when the second stabilizing layer 6 is not coated with hot melt adhesive for polyester tape) or under the sintering situation (such as the second stabilizing layer 6 is polytetrafluoroethylene PTFE (or then stretched polytetrafluoroethylene) tape can continue to extrude the sheath layer 7 outside the second stable layer 6 .

[0171] Sheath layer 7, preferably made of a polymeric resin such as polyvinyl chlo...

Embodiment 3

[0173] Figure 12 A schematic diagram showing the structure of a differential signal cable 1C according to Embodiment 3 of the high-speed digital signal transmission cable of the present invention, which is shown as having an insulated core wire 2 , a shielding layer 3 , a first stabilizing layer 5 and an optional drain wire 4 . Components having common functions to those described in 1A are denoted by the same reference numerals, and their descriptions are omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com