Post-printing processing process for high-speed mechanical packaging medicine packaging box

A technology of post-press processing and processing technology, which is applied in the field of pharmaceutical packaging box processing. It can solve the problems of weak glued boxes, irregular box shapes after box formation, and degumming of cartons, so as to prevent irregular box shapes and improve box shape. Zhouzheng degree, to avoid the effect of indentation is not full

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

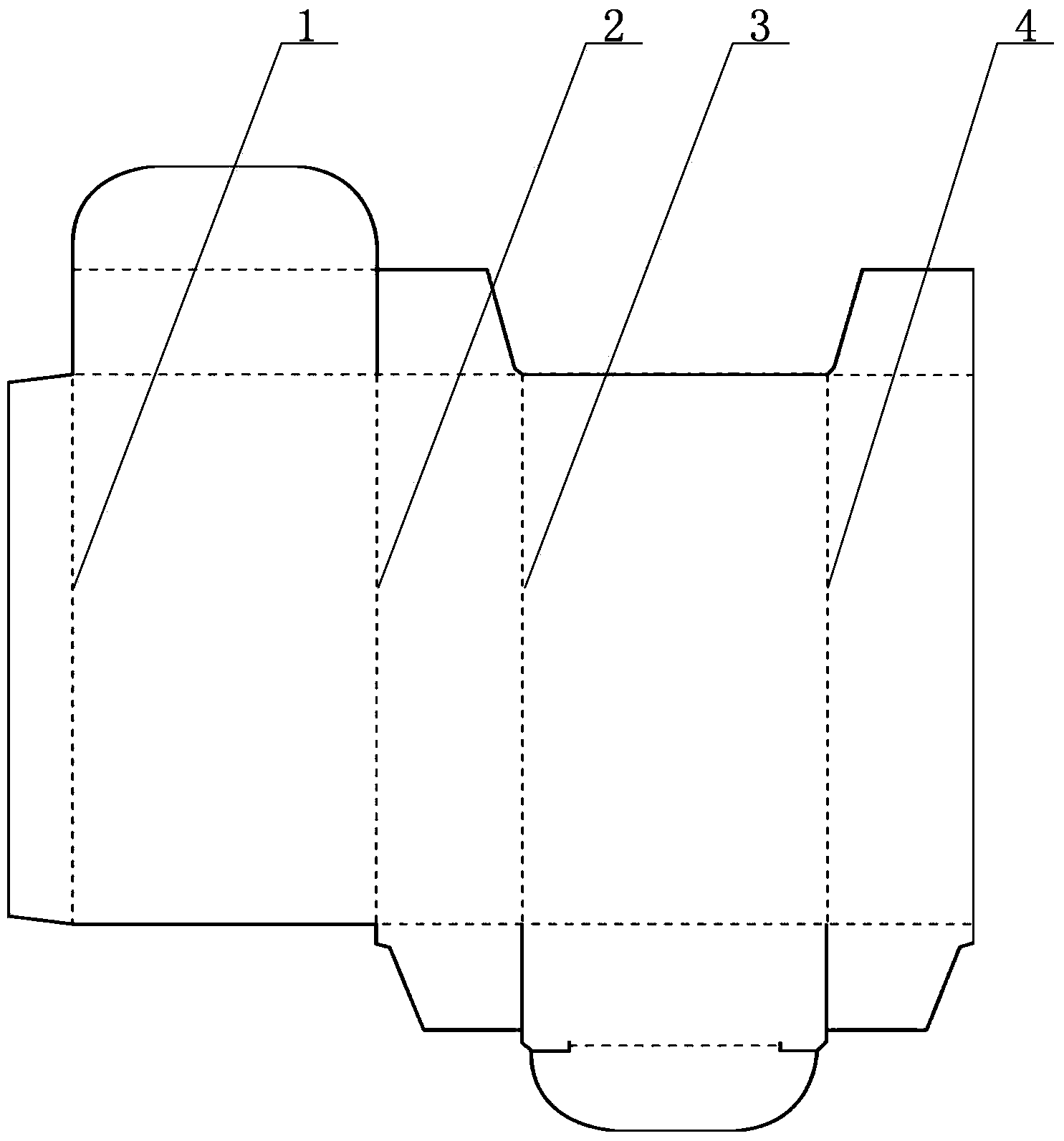

Image

Examples

Embodiment 1

[0030] The post-press processing technology of the high-speed machine-loaded medicine packaging box described in the present invention includes a die-cutting creasing technology and a box-gluing processing technology.

[0031] The die-cutting machine used in the die-cutting and creasing process is Youheng MK-1050 automatic flat die-cutting machine produced by Tianjin Changrong Printing Equipment Co., Ltd. The specific die-cutting and creasing process includes the following steps:

[0032] ① Knife arrangement: Before molding, the die-cutting plate is made according to the design requirements of the product. The paper of the medicine packaging box is 300g white cardboard, and its thickness c is 0.40mm. In this process, the bottom mold made of resin material is used , under the premise of ensuring that the paper will not be crushed, break through the routine, choose a pointed steel wire with a thickness of 0.71mm as the die-cutting steel wire, choose a die-cutting knife line with ...

Embodiment 2

[0049] The paper of the medicine packaging box is 250g white cardboard, its thickness c is 0.32mm, and the indentation width B=1.5c+d-N=(1.5*0.30+0.71-0.06)mm=1.10mm is determined, and it is customized to match the die-cutting knife line Matching die-cut wire, die-cut wire height X h =D h -c+0.05=(23.8-0.30+0.05)mm=24.00mm, during processing, control the temperature of the pasting box working environment at 23°C~24°C, relative humidity at 65%~70%, and use glue with a viscosity of 7500cps Adhesive, glue coating thickness is 0.25mm, the machines and process steps used in this embodiment are the same as those in Embodiment 1.

[0050] In this example, the conventional indentation width of 1.16mm is changed to 1.10mm, and the matching value of the conventional 23.8mm die-cutting knife line and 23.50mm die-cutting steel wire is changed to 23.8mm die-cutting knife line and 24.00mm The matching value of the die-cutting steel wire in mm improves the matching accuracy of the die-cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com