Formula of soft polyurethane composite waterproof sound-absorbing film

A soft polyurethane and sound film technology, applied in the field of polyurethane foaming technology, can solve the problems of uneven coating, uneven surface, poor heat insulation and waterproof effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

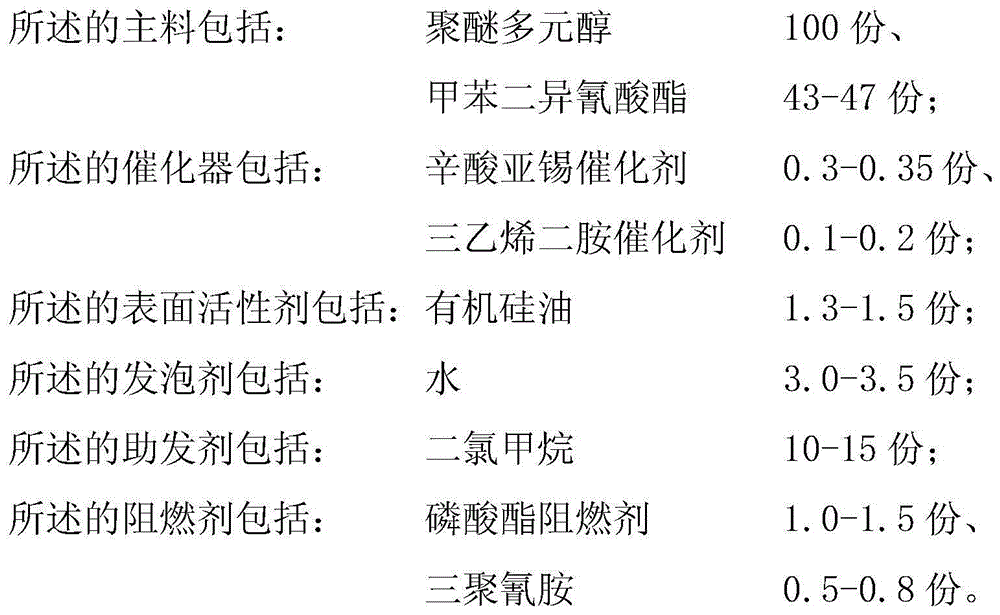

[0009] A formula of soft polyurethane composite waterproof and sound-absorbing membrane, which consists of the following raw materials in parts by weight:

[0010]

[0011] As a preferred embodiment of the present invention, the above-mentioned formulas all select the models noted in brackets for use.

Embodiment 2

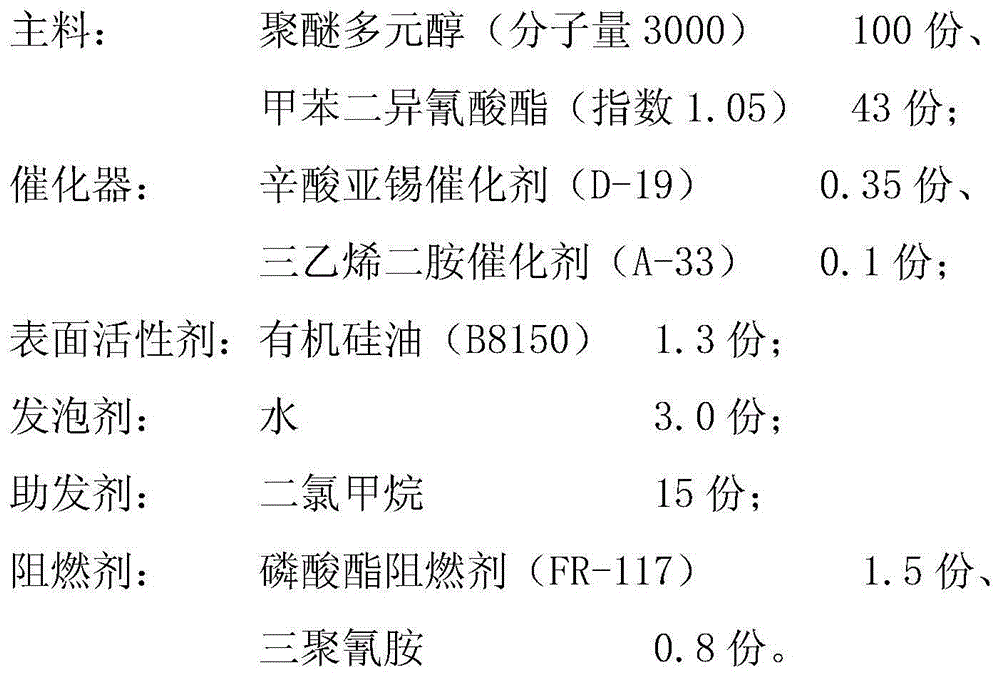

[0013] A formula of soft polyurethane composite waterproof and sound-absorbing membrane, which consists of the following raw materials in parts by weight:

[0014]

[0015]

[0016] As a preferred embodiment of the present invention, the above-mentioned formulas all select the models noted in brackets for use.

Embodiment 3

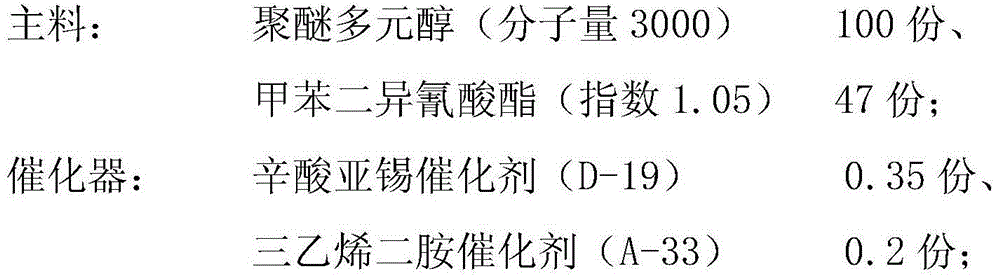

[0018] A formula of soft polyurethane composite waterproof and sound-absorbing membrane, which consists of the following raw materials in parts by weight:

[0019]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com