Powder metallurgy technical formula and technical process thereof

A powder metallurgy and process formula technology, applied in the field of metallurgical process, can solve the problems of poor adaptability to special process requirements, affecting product performance and strength, and increasing production costs of enterprises, achieving considerable benefits, improving production efficiency, and improving the economic efficiency of enterprises. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0030] A powder metallurgy process formula in the present invention is to replace the original electrolytic copper as process formula material with phosphorus-iron alloy material, and its process formula is uniformly mixed with graphite powder, copper powder, manganese sulfate, phosphorus-iron alloy, zinc stearate and iron powder Iron-based powder is formed; in the iron-based powder, by weight, the graphite powder is 0.4% to 1.5%, the copper powder is 1% to 3%, and the manganese sulfide is 1% to 2.5%, Ferrophosphorus alloy is 1% to 4%, zinc stearate is 0.5% to 1%, and iron powder is 70% to 98%.

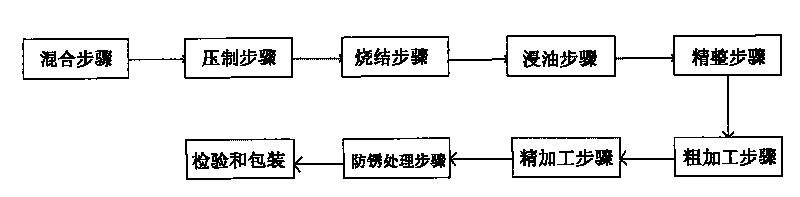

[0031] see figure 1 , the technical process of the present invention comprises:

[0032] (1) Mixing step: the iron-based powder is evenly mixed accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com