Zn-Ca compound stabilizer

A calcium-zinc composite and stabilizer technology, applied in the field of calcium-zinc composite stabilizers, can solve the problems of short continuous production operation period, easy dust pollution, poor production stability, etc., to extend the extrusion production cycle and achieve good production stability , the effect of long production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 28 parts by weight of zinc stearate, 8.8 parts of calcium stearate, 20.5 parts of hydrotalcite, 17.7 parts of polyols, 10.3 parts of β-diketones, 6.6 parts of G60, 7.1 parts of G22 and 2.5 parts of tetrakis[methyl-β -(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester is automatically metered and added to the reaction kettle, the blade is stirred at 57 rpm, and after stirring for 35 minutes, the blade drops to 40 rpm Cutting and packaging in seconds.

Embodiment 2

[0055] 31.5 parts of zinc stearate, 9.7 parts of calcium stearate, 29.8 parts of hydrotalcite, 16.3 parts of polyols, 4.5 parts of β-diketones, 4.6 parts of G60, 6.3 parts of G22 and 1.5 parts of tetrakis[methyl-β- (3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester is automatically metered and added to the reaction kettle, the blade is stirred at 55 rpm, and after stirring for about 32 minutes, the blade drops to 38 rpm Cutting and packaging in seconds.

Embodiment 3

[0057]30.8 parts by weight of zinc stearate, 8.5 parts of calcium stearate, 29.8 parts of hydrotalcite, 17.6 parts of polyols, 5.5 parts of β-diketones, 6.8 parts of G60, 4.5 parts of G22 and 1.25 parts of tetrakis[methyl-β -(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester is automatically metered and added to the reaction kettle, the blade is stirred at 58 rpm, and after stirring for 28 minutes, the blade drops to 40 rpm Cutting and packaging in seconds.

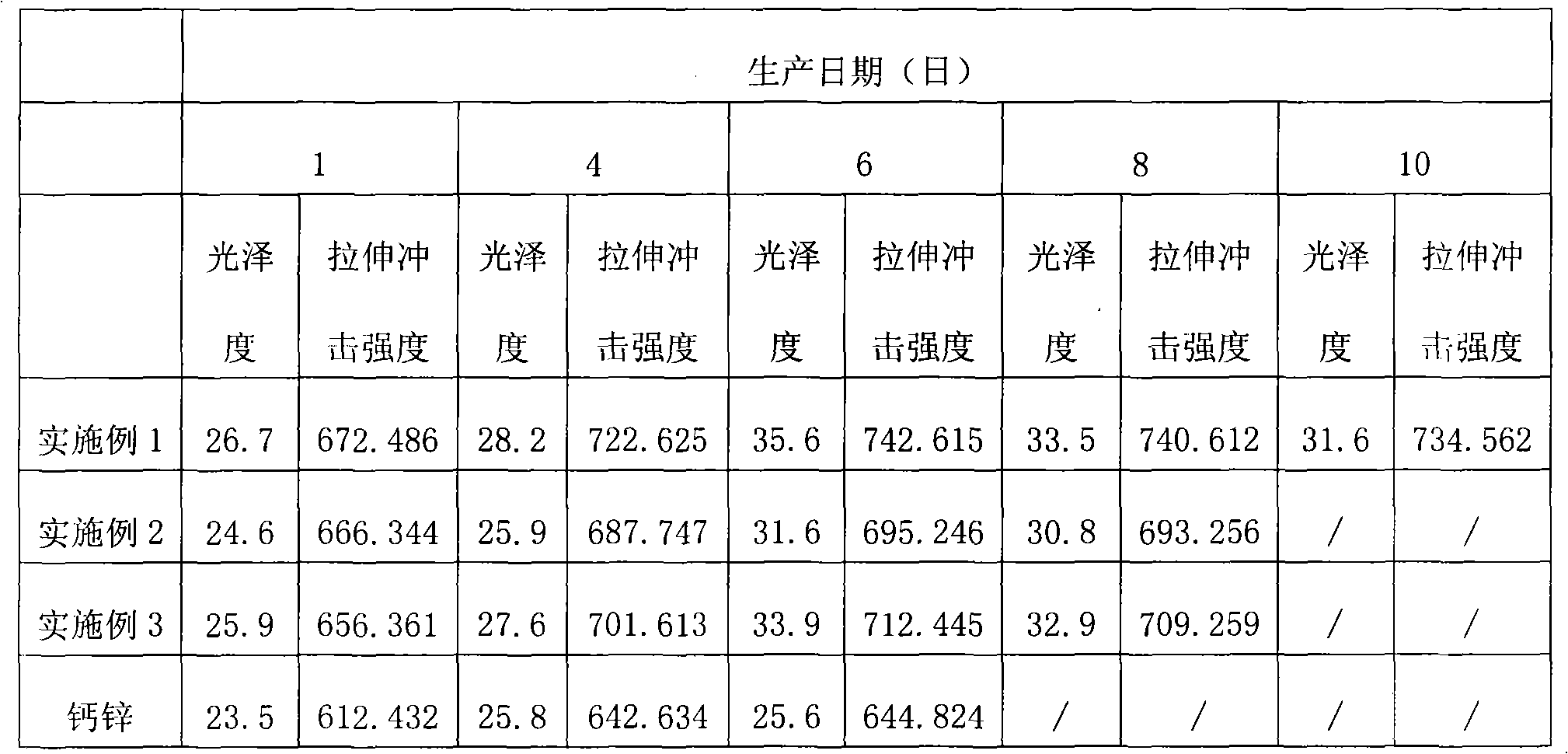

[0058] Embodiment 1-3 and the technical index of the PVC profiles that existing use calcium-zinc stabilizer production are as shown in table 1, table 2 and table 3:

[0059] The model of the calcium zinc stabilizer is WWP-HLB2, produced by Guangdong Weilinna Company.

[0060] Table 1

[0061]

Flexural modulus of elasticity

Charpy impact strength

Tensile impact strength

Example 1

2798.05

23.012

734.582

Example 2

2812.47

22.072

695.348

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com