Novel slow-release environment-friendly stabilizer applied to U-PVC large-caliber water supply accessory

An environmentally friendly stabilizer, slow-release technology, applied in the field of U-PVC large-diameter water supply accessories environmental stabilizer, to achieve the effects of not easy precipitation, reducing discoloration, and slow degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

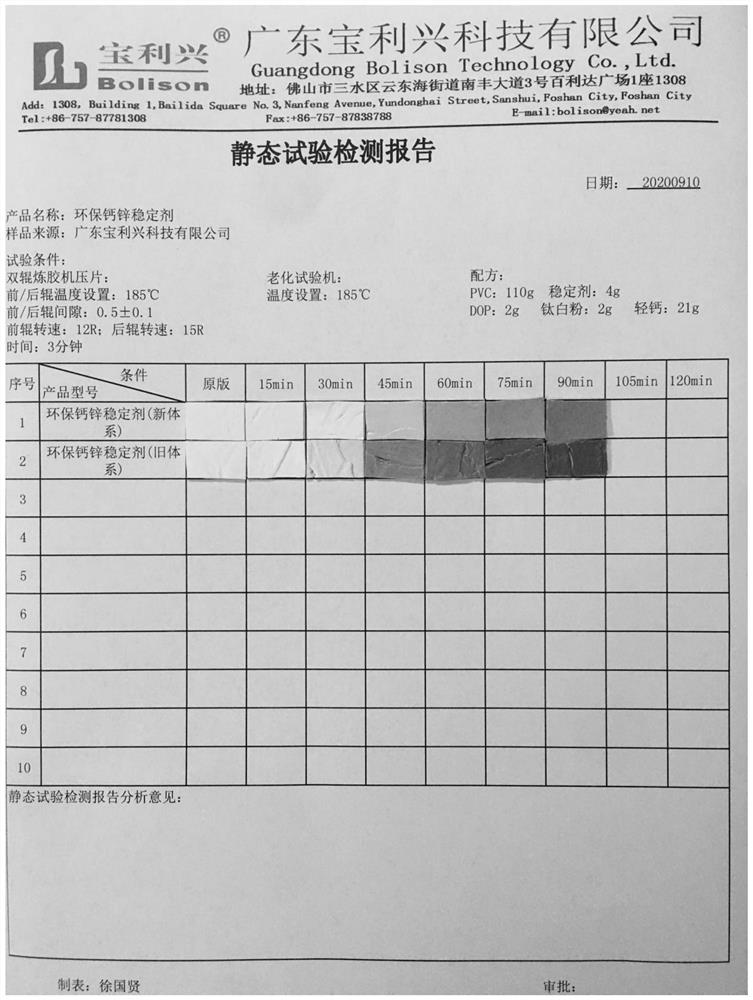

Image

Examples

Embodiment

[0037] A new slow-release environmentally friendly stabilizer for U-PVC large-diameter water supply fittings, using raw materials containing the following weight percentages:

[0039] Calcium stearate 6%;

[0040] Syke 5%;

[0041] Uracil 5%;

[0042] Zeolite 28%;

[0044] Antioxidant 4%;

[0045] Synergistic heat stabilizer 5%;

[0046] Polyol 5%;

[0047] Lanthanum maleamate 4%.

[0048] Prepared by following steps:

[0049] Step 1. Add zinc stearate, calcium stearate, syke, 1,3-dimethyl-6-aminouracil, polyol and lanthanum maleamate to the reaction kettle in sequence at 35°C in proportion Stir evenly in medium for 18min;

[0050] Step 2, add zeolite and calcium hydroxide and mix and stir for 20 minutes;

[0051] Step 3. Finally, add synergistic stabilizers, antioxidants, light stabilizers and ultraviolet absorbers, stir for 9 minutes at 75°C under nitrogen protection, and obtain PVC stabilizers after cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com