EVA (ethylene vinyl-acetate copolymer) sole material and preparation method thereof

A shoe sole material and graphene dispersion technology, applied in the field of shoe sole composite materials, can solve the problems that the wear resistance is not as good as that of rubber, hinder the application of high-end shoes, and the service life is not long, so as to achieve good wear resistance, improved anti-skid performance, and not easy to wear. broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method of EVA sole material, it may further comprise the steps:

[0035] 1) Take each component material according to the above proportioning ratio;

[0036] 2) Place the weighed graphene in the graphene organic dispersion (GSOS, produced by Ningbo Moxi Technology Co., Ltd.), stir evenly, and ultrasonically vibrate for 30 minutes to prepare the graphene dispersion for subsequent use;

[0037] 3) Stir and mix the other components except azodicarbonamide and dicumyl peroxide and the graphene dispersion at 85-90°C; put it in an internal mixer, add azodicarbonamide , dicumyl peroxide, banburying at 105-110°C for 10-15min;

[0038] 4) After banburying, carry out kneading and granulation, the temperature of said kneading and granulation is 80-85°C;

[0039] 5) Put the pellets in step 4) into a foaming machine for foaming. The foaming temperature is 150-160° C., the pressure is 165kg-175kg, and the foaming time is 5-10 minutes to obtain the shoe sole material. ...

Embodiment 1

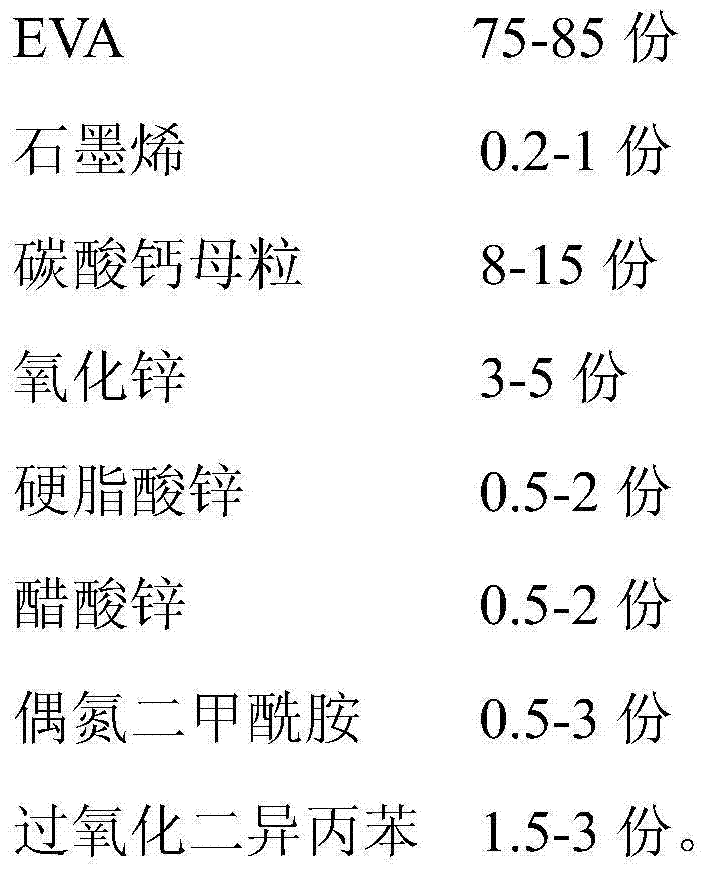

[0044] A kind of EVA sole material, it is made up of the component of following parts by weight:

[0045]

[0046] The preparation method of above-mentioned EVA sole material, it may further comprise the steps:

[0047] 1) Take each component material according to the above proportioning ratio;

[0048] 2) Place the weighed graphene in the graphene organic dispersion (GSOS, produced by Ningbo Moxi Technology Co., Ltd.), stir evenly, and ultrasonically vibrate for 30 minutes to prepare the graphene dispersion for subsequent use;

[0049] 3) After stirring and mixing other components except azodicarbonamide and dicumyl peroxide and graphene dispersion liquid at 85° C.; Dicumyl oxide, banburying at 105°C for 10 minutes;

[0050] 4) After banburying is finished, carry out kneading and granulation, and the temperature of said kneading and granulation is 80°C;

[0051] 5) The pellets in step 4) are placed in a foaming machine for foaming. The foaming temperature is 150° C., th...

Embodiment 2

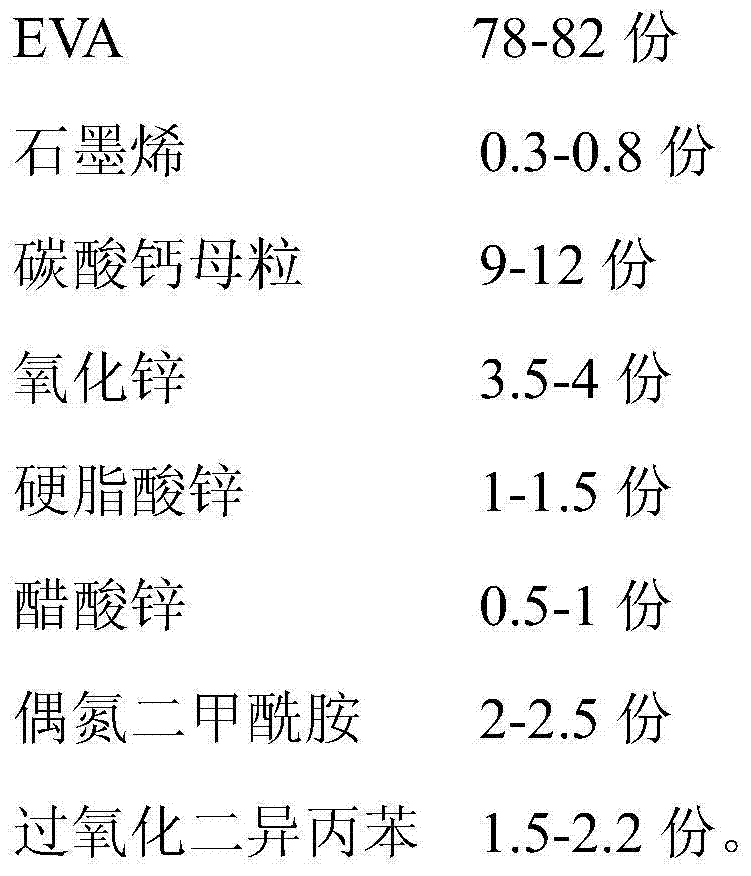

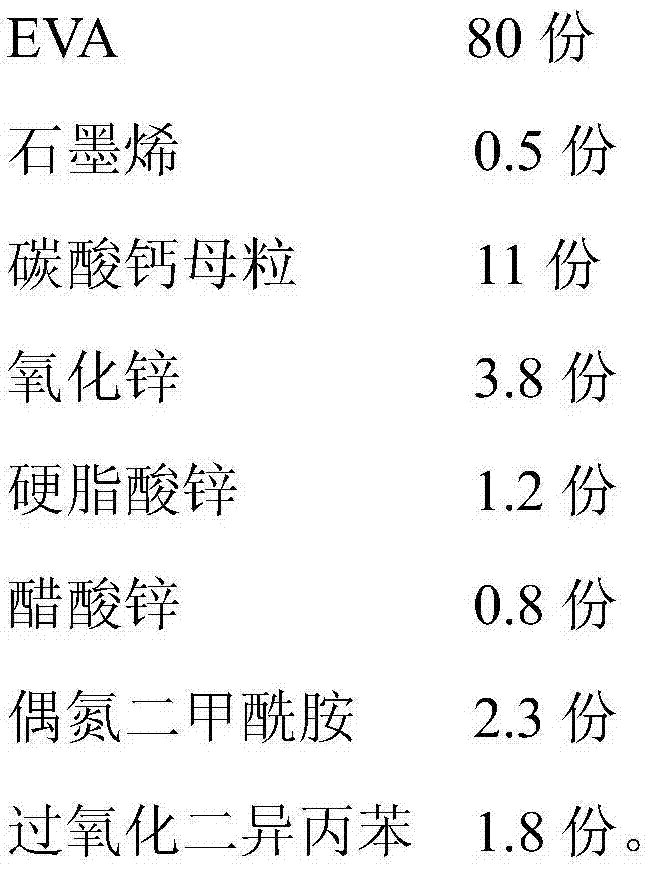

[0054] A kind of EVA sole material, it is made up of the component of following parts by weight:

[0055]

[0056] The preparation method of above-mentioned EVA sole material, it may further comprise the steps:

[0057] 1) Take each component material according to the above proportioning ratio;

[0058] 2) Place the weighed graphene in the graphene organic dispersion (GSOS, produced by Ningbo Moxi Technology Co., Ltd.), stir evenly, and ultrasonically vibrate for 30 minutes to prepare the graphene dispersion for subsequent use;

[0059] 3) After stirring and mixing other components except azodicarbonamide and dicumyl peroxide and graphene dispersion liquid at 88° C.; Dicumyl oxide, banburying at 109°C for 15 minutes;

[0060] 4) After banburying is finished, carry out kneading and granulation, and the temperature of said kneading and granulation is 85°C;

[0061] 5) Put the pellets in step 4) into a foaming machine for foaming. The foaming temperature is 155° C., the press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com