Flexible, highly-elastic and wear-resistant EVA foamed shoe and manufaturing method thereof

A manufacturing method, high-elastic technology, applied in the direction of soles, footwear, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 6

[0046] The formula of embodiment 6 is shown in table 7.

[0047] Table 7

[0048] raw material name

Mass percentage (%)

EVA360

33

EVA40L-03

13

SEBS

13

POE9061

13

OBC S 9107

10

5

Anti-wear agent

6

0.4

0.7

0.9

BIPB

0.5

Azo blowing agent

1.8

2.7

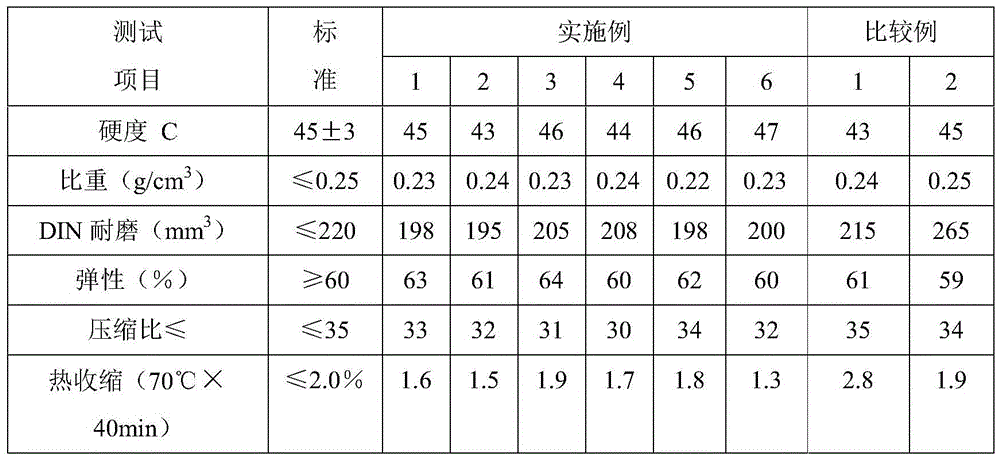

[0049] In order to better explain the research results, the ratio of the soft, high-elastic and wear-resistant EVA foam shoe material was changed respectively so that some of the raw materials were not within the set range. Comparative Example 1 (see Table 8) was to change the main components of the two materials. The ratio of the rubber material is not within the set range. Comparative example 2 (see Table 9) is to change the auxiliary materials of the two materials so that it is not within the set range, and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com