Water expansion type fire-proof mildew-proof coating for tunnels

An intumescent, tunneling technology, applied in fire-resistant coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of cumbersome construction, thick coating construction, and difficult toning of color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

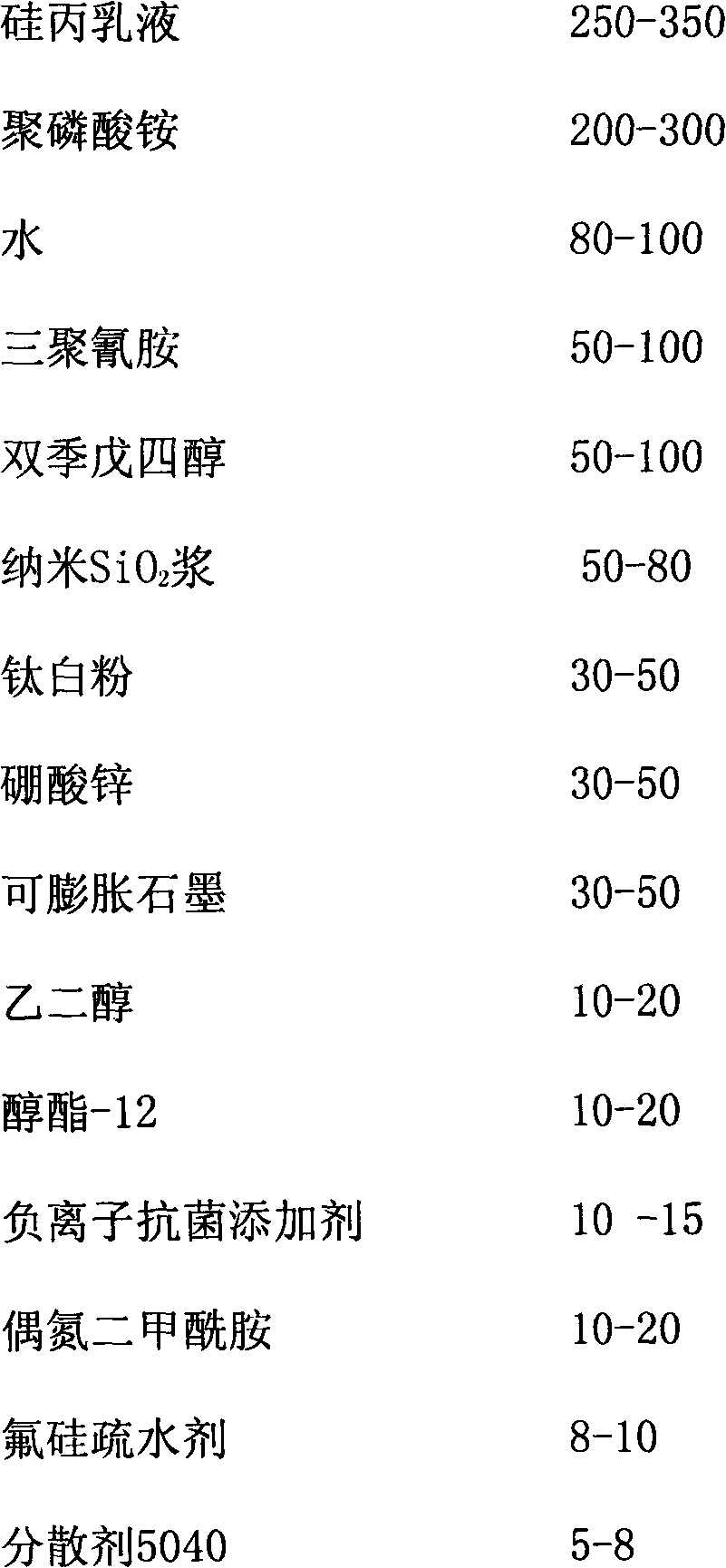

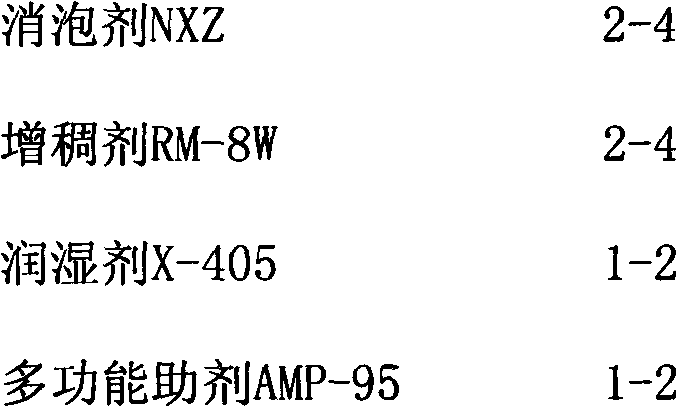

[0019] The present invention is further described in detail below in conjunction with specific examples: a water-based expansion type tunnel fire-proof and mildew-proof coating, with silicon-acrylic emulsion as film-forming material, modified ammonium polyphosphate, melamine, dipentaerythritol, and azodicarbonamide as barrier Combustion agent, with titanium dioxide, zinc borate, expandable graphite as filler, nano-SiO 2 It is a modified material, using negative ion antibacterial additives as antifungal and fungicides, and is prepared through conventional preparation processes with the help of additives. The composition of the formula is as follows, and the measurement unit is based on mass fraction:

[0020]

[0021]

[0022] The preparation process of the water-based intumescent tunnel fire-proof and mildew-proof coating is as follows: first add water into the dispersion tank, add wetting agent X-405, multifunctional additive AMP-95, dispersant 5040, azodicarbonamide, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com