Wood plastic composite dalle and preparation method thereof

A wood-plastic composite material and decorative board technology, applied in the field of wood-plastic composite decorative board and its preparation, can solve the problems of inability to absorb toxic and harmful gases, underutilization, high price, etc., and achieve light weight, low density and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

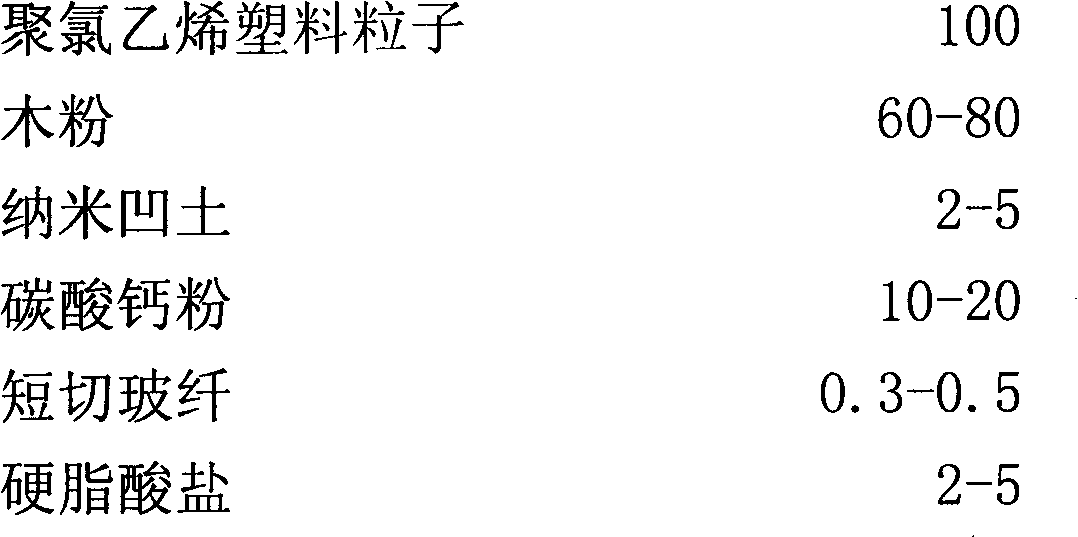

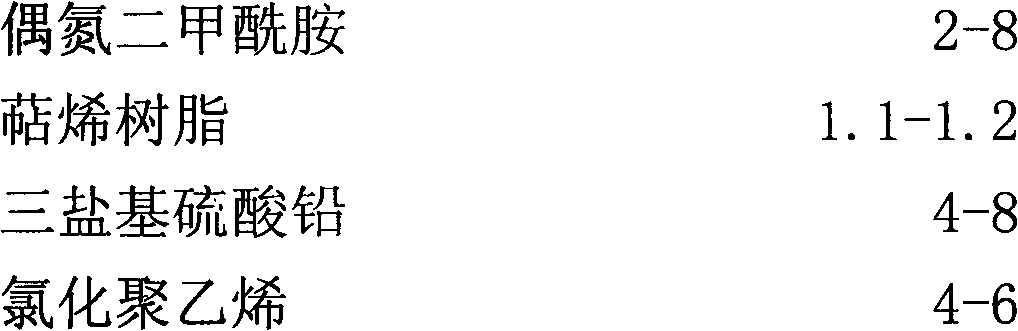

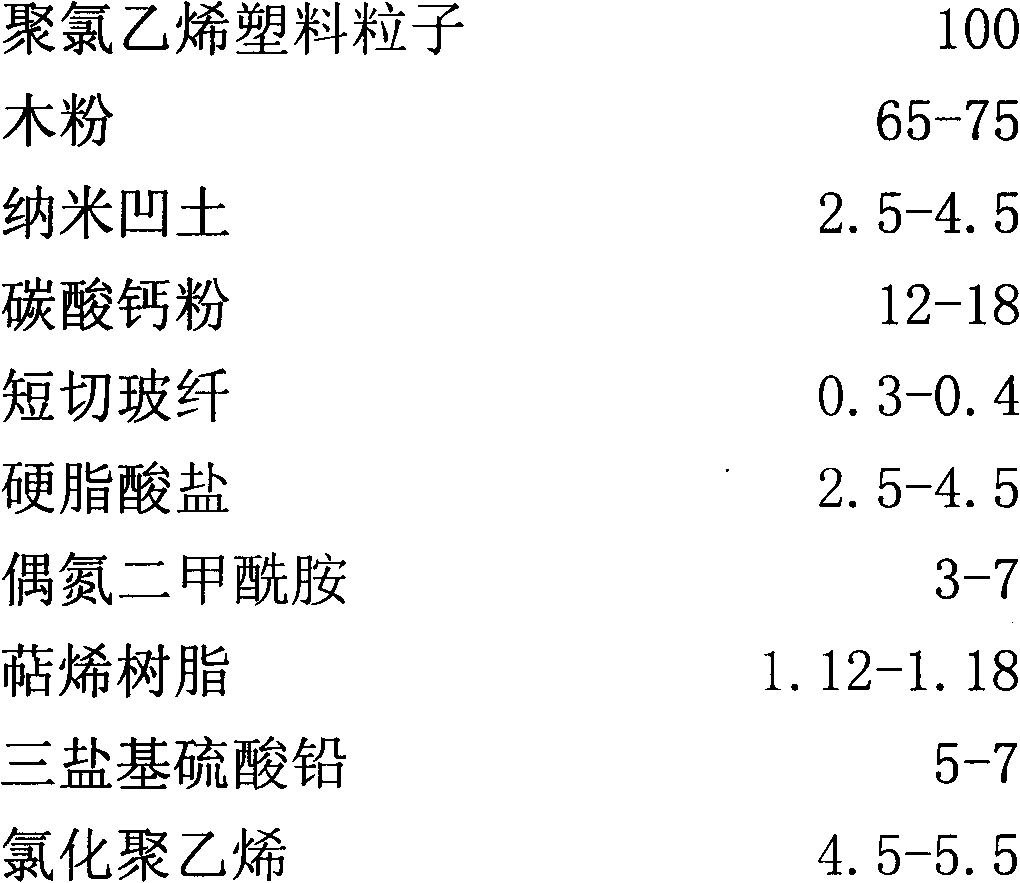

[0027] Polyvinyl chloride plastic particles 100, wood flour (80 mesh) 70, nano attapulgite (40nm) 3, calcium carbonate powder (1000 mesh) 15, chopped glass fiber (3.5mm) 0.4, zinc stearate 4, azo Diformamide 5, terpene resin 1.15, tribasic lead sulfate 6, chlorinated polyethylene 5.

[0028] (1) take each raw material by formula quantity;

[0029] (2) Polyvinyl chloride plastic particles, nano-attapulgite, calcium carbonate powder, chopped glass fiber, terpene resin, chlorinated polyethylene, tribasic lead sulfate, and zinc stearate are placed in a mechanical stirring tank and stirred for 10 Minutes, then extrude and granulate, the temperature of the barrel of the extruder is 155°C, and the temperature of the die head is 175°C to obtain modified plastic particles;

[0030] (3) Place the above-mentioned modified plastic particles, wood powder, and azodicarbonamide in a mechanically stirred tank and mechanically stir again for 3 minutes;

[0031] (4) After mixing, use an extru...

Embodiment 2

[0034] Polyvinyl chloride plastic particles 100, wood flour (60 mesh) 60, nanometer attapulgite (20nm) 2, calcium carbonate powder (800 mesh) 10, chopped glass fiber (3mm) 0.3, calcium stearate 2, azobis Formamide 2, terpene resin 1.1, tribasic lead sulfate 4, chlorinated polyethylene 4.

[0035] (1) take each raw material by formula quantity;

[0036] (2) Polyvinyl chloride plastic particles, nano attapulgite, calcium carbonate powder, chopped glass fiber, terpene resin, chlorinated polyethylene, tribasic lead sulfate, and stearate are placed in a mechanical stirring tank and stirred for 6 Minutes, then extrude and granulate, the temperature of the barrel of the extruder is 155°C, and the temperature of the die head is 160°C to obtain modified plastic particles;

[0037] (3) Place the above-mentioned modified plastic particles, wood powder, and azodicarbonamide in a mechanically stirred tank and mechanically stir again for 3 minutes;

[0038] (4) After mixing, use an extrud...

Embodiment 3

[0041] Polyvinyl chloride plastic particles 100, wood powder (80 mesh) 80, nano attapulgite (50nm) 5, calcium carbonate powder (1500 mesh) 20, chopped glass fiber (4mm) 0.5, zinc stearate 5, azobis Formamide 8, terpene resin 1.2, tribasic lead sulfate 8, chlorinated polyethylene 6.

[0042] (1) take each raw material by formula quantity;

[0043] (2) Polyvinyl chloride plastic particles, nano-attapulgite, calcium carbonate powder, chopped glass fiber, terpene resin, chlorinated polyethylene, tribasic lead sulfate, and stearate are placed in a mechanical stirring tank and stirred for 10 Minutes, then extrude and granulate, the extruder barrel temperature is 175°C, the die head temperature is 175°C, and modified plastic particles are obtained;

[0044] (3) Place the above-mentioned modified plastic particles, wood powder, and azodicarbonamide in a mechanically stirred kettle and mechanically stir again for 5 minutes;

[0045] (4) After mixing, use an extruder to carry out melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com