Method for preparing low-polymerization-degree polyformaldehyde dialkyl ether from mixture of lower alcohols and application thereof

A formaldehyde dialkyl ether and low-carbon mixed alcohol technology, applied in the preparation of organic compounds, chemical instruments and methods, liquid carbon-containing fuels, etc., can solve the problems of low effective content and high polymerization degree requirements, and achieve the preparation process Simple, good process technology route, obvious economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

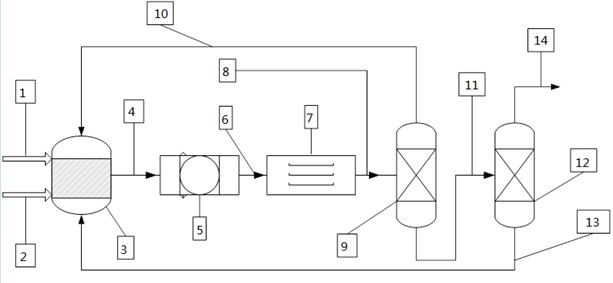

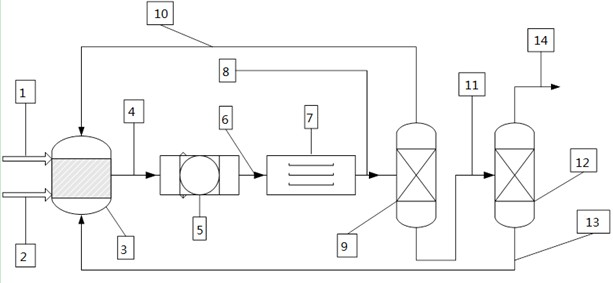

Image

Examples

Embodiment 1

[0047] Preparation of Polyoxymethylene Dialkyl Ether C with Low Polymerization Degree from Mixed Alcohols n h 2n+1 O(CH 2 O) m C n h 2n+1 The method is:

[0048] Add low-carbon mixed alcohol and anhydrous low-degree-of-polymerization paraformaldehyde in the batch-type high-pressure reactor in a molar ratio of 1:2, and choose to account for about 2% of the total mass of low-carbon mixed alcohol and anhydrous low-polymerization-degree paraformaldehyde P-toluenesulfonic acid is used as a catalyst to catalyze and put into the reactor together, fill the air in the reactor with nitrogen, control the initial pressure of the reactor to 0.2Mpa, and keep the reaction at a constant temperature of 90-100°C for 12 hours under stirring at 100rpm. After the reaction is completed, go through the above-mentioned extraction and separation process steps, separate and finally collect the fraction at 150-340° C., and refine the obtained product. According to the detection by chromatography-...

Embodiment 2

[0051] Preparation of Polyoxymethylene Dialkyl Ether C with Low Polymerization Degree from Mixed Alcohols n h 2n+1 O(CH 2 O) m C n h 2n+1 The method is:

[0052] The mixture of low-carbon mixed alcohol, anhydrous trioxane and anhydrous formaldehyde obtained in the alcohol production process is sequentially added in a molar ratio of 1:1 to the intermittent high-pressure reactor, and the low-carbon mixed alcohol, anhydrous trimer 5% of the total mass of formaldehyde and anhydrous formaldehyde is put into the reaction kettle together as a catalyst, and the air in the reaction kettle is replaced by filling inert gas. -200°C constant temperature reaction for 10 hours. After the reaction is completed, go through the above-mentioned extraction and separation process steps, separate and finally collect the fraction at 150-340° C., and refine the obtained product. The GC-MS method shows that the product distribution of each degree of polymerization is: m=1, 27.6%; m=2, 20.4%; m...

Embodiment 3

[0055] Preparation of Polyoxymethylene Dialkyl Ether C with Low Polymerization Degree from Mixed Alcohols n h 2n+1 O(CH 2 O) m C n h 2n+1 The method is:

[0056]Add low-carbon mixed alcohol and anhydrous paraformaldehyde successively in the proportion of molar ratio 2:3 in the intermittent high-pressure reactor, and select trifluoromethanesulfonic acid and The mixture of p-toluenesulfonic acid is put into the reaction kettle together as a catalyst, and the air in the reaction kettle is replaced by nitrogen gas, the initial pressure of the reaction kettle is controlled to 0.6Mpa, and the reaction temperature is maintained at 70-90°C for 10 hours under stirring at 100rpm. After the reaction is completed, go through the above-mentioned extraction and separation process steps, separate and finally collect the fraction at 150-340° C., and refine the obtained product. According to the detection by GC-MS method, the product distribution of each degree of polymerization is: m=1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com