Sucker rod with composite spiral abrasion-resistant layer, manufacturing device and manufacturing method

A sucker rod and wear-resistant layer technology, applied in drill pipe, earthwork drilling, drilling equipment and other directions, can solve the problems of long service life, insufficient toughness and strength, high wear resistance and high durability, and achieve high bonding strength and production efficiency. The effect of high, excellent uneven wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

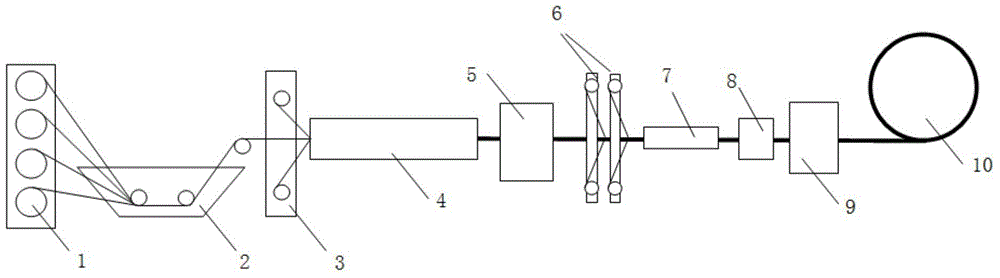

[0034] A plurality of 12K bundles of T300 carbon fiber filaments are drawn out from the wire drawing frame 1. Driven by the traction of the traction device 9, the T300 carbon fiber bundles enter the dipping tank 2 to fully impregnate the glue solution. The traction speed of the traction device is 1000mm / min. The surface of the T300 carbon fiber tow fully impregnated with epoxy resin glue is covered with a narrow glass fiber tape under the action of the glass fiber tape coating device 3, and under the power of the traction device, it enters the sucker rod body forming mold 4 together for the initial Curing, curing and molding temperature according to the order of entering and exiting the mold: 140°C\160°C\200°C, molding time is 2 minutes, and the diameter of the final formed carbon fiber composite sucker rod is 8mm. The formed carbon fiber composite continuous sucker rod that has been cured for the first time enters the secondary curing furnace 5 for secondary curing molding. Th...

Embodiment 2

[0036] A plurality of 12K bundles of T700 carbon fiber filaments are drawn out from the wire drawing frame 1. Driven by the traction of the traction device 9, the T700 carbon fiber bundles enter the dipping tank 2 to fully impregnate the glue solution. The traction speed of the traction device is 600mm / min. The surface of the T700 carbon fiber tow fully impregnated with epoxy resin glue is covered with a narrow glass fiber tape under the action of the glass fiber tape coating device 3, and under the power of the traction device, it enters the sucker rod body forming mold 4 together for the initial Curing, curing molding temperature according to the order of entering and exiting the mold: 150 ° C \ 170 ° C \ 210 ° C, the molding time is 3 minutes, and the diameter of the carbon fiber composite sucker rod body after the final molding is 9 mm. The formed carbon fiber composite continuous sucker rod that has been cured for the first time enters the secondary curing furnace 5 for se...

Embodiment 3

[0038] A plurality of 6K bundles of T700 carbon fiber filaments are drawn out from the wire drawing frame 1. Driven by the traction of the traction device 9, the T700 carbon fiber bundles enter the dipping tank 2 to fully impregnate the glue solution. The traction speed of the traction device is 300mm / min. The surface of the T700 carbon fiber tow fully impregnated with polyurethane resin glue is covered with a narrow glass fiber tape under the action of the glass fiber tape coating device 3, and under the power of the traction device, it enters the sucker rod body forming mold 4 for initial curing , the curing molding temperature according to the order of entering and exiting the mold is: 155 ° C \ 175 ° C \ 200 ° C, the molding time is 2.5 minutes, and the diameter of the carbon fiber composite sucker rod body after the final molding is 8 mm. The formed carbon fiber composite continuous sucker rod that has been cured for the first time enters the secondary curing furnace 5 for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com