Pneumatic tire

A pneumatic tire, tire circumferential technology, applied to tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problem of insufficient suppression of local partial wear at the main rib, deterioration of tear resistance, Rigidity reduction and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

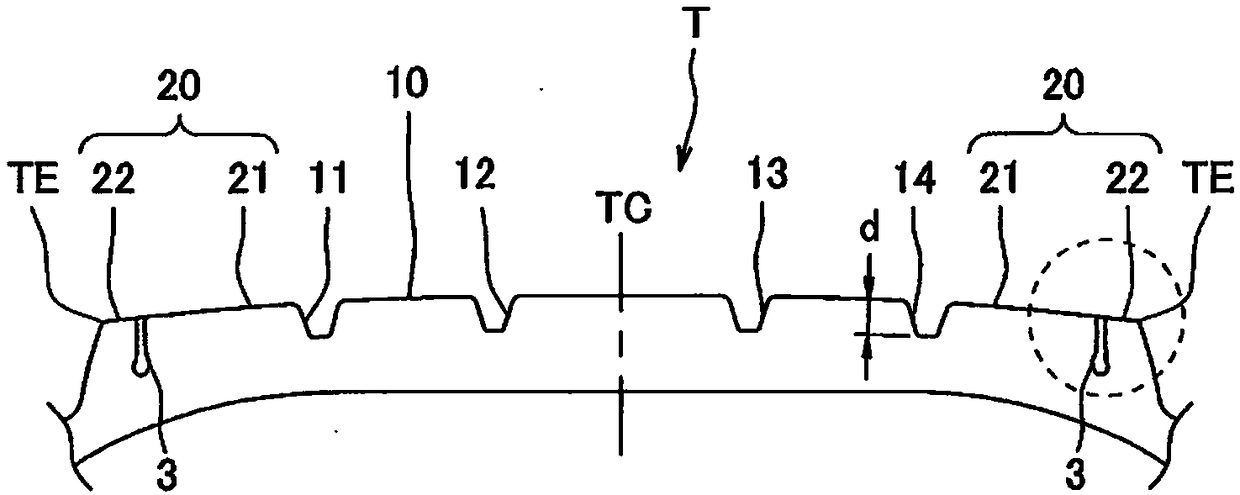

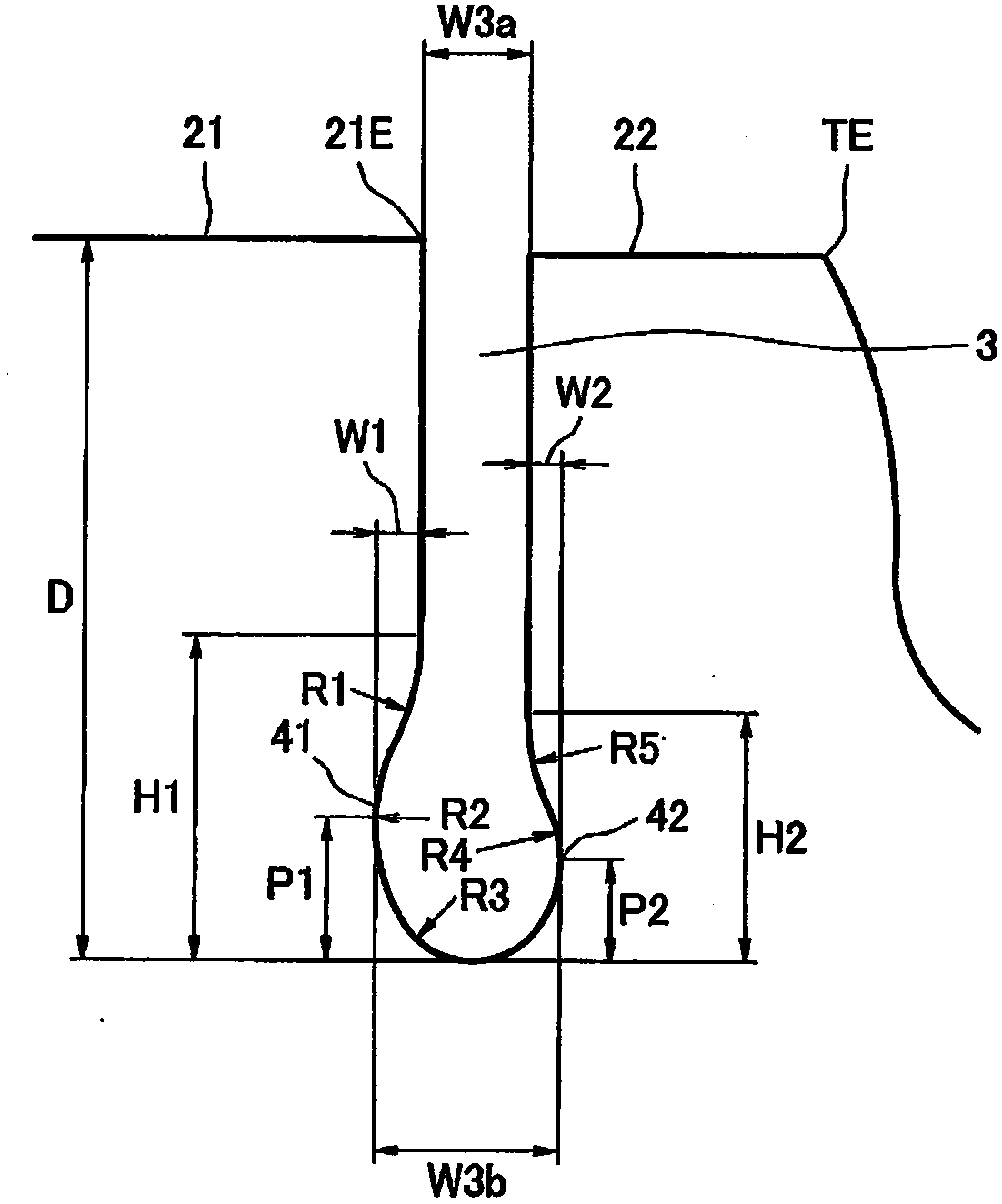

[0020] Embodiments of the present invention will be described with reference to the drawings. figure 1 The tread 10 of the pneumatic tire T of the present embodiment is schematically shown. figure 2 Will figure 1 An enlargement of the main part surrounded by the dotted box is given.

[0021] This pneumatic tire T has a pair of beads (not shown) and a pair of sidewalls extending outward in the tire radial direction from the beads in the same way as a normal pneumatic tire. connected to the outer end. In addition, a carcass extending in an annular shape is provided between a pair of beads, and reinforcing members such as a belt for reinforcing the carcass are embedded in the tread 10 , but illustration of these is omitted.

[0022] A plurality of main grooves extending in the tire circumferential direction are formed on the tread 10 , and in the present embodiment, four main grooves 11 to 14 are formed. The tread 10 is divided into a plurality of land portions including a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com