Inflatable load-carrying radial tire

A technology of radial tires and tires, applied to tire parts, tire sidewalls, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] See attached picture.

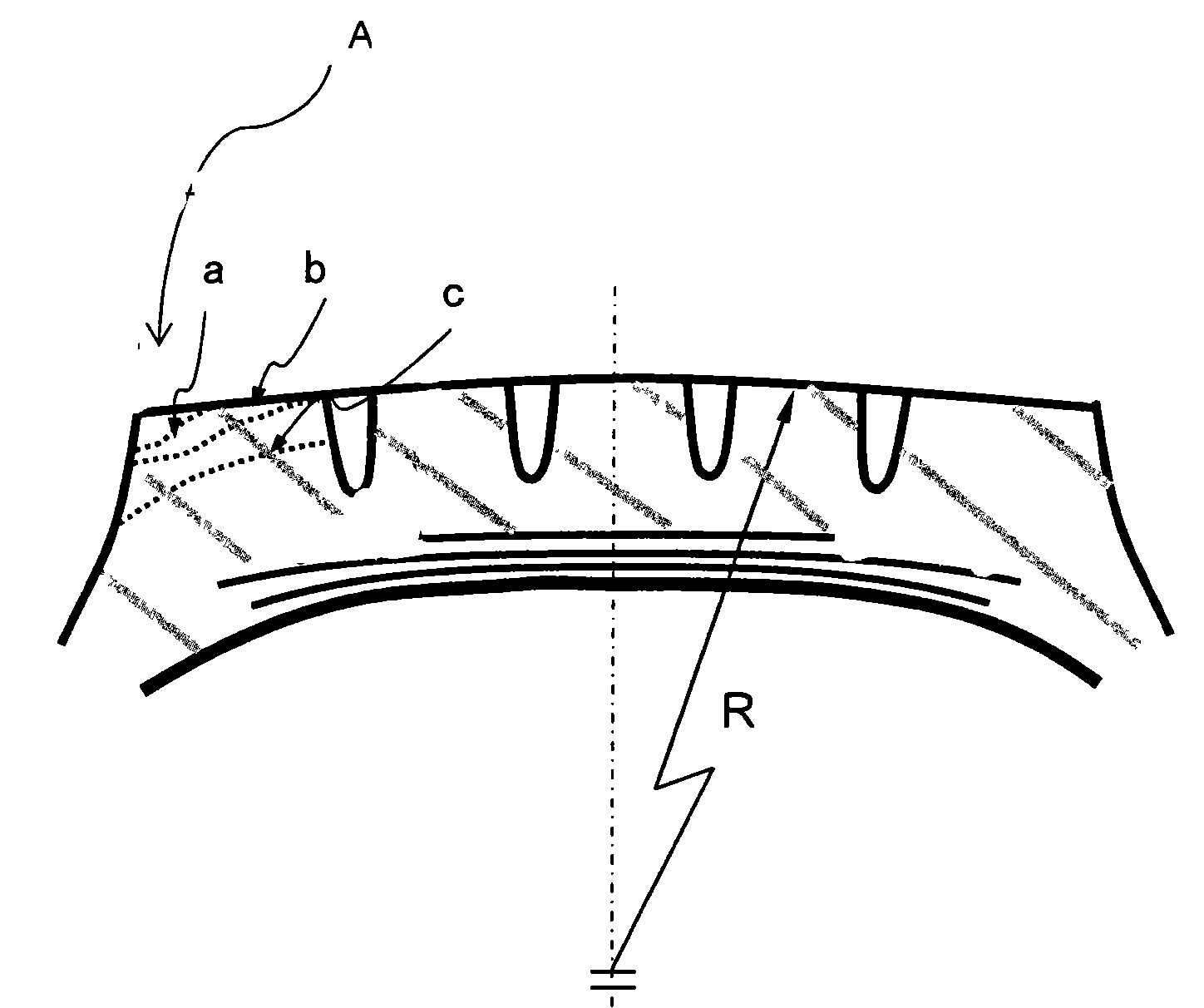

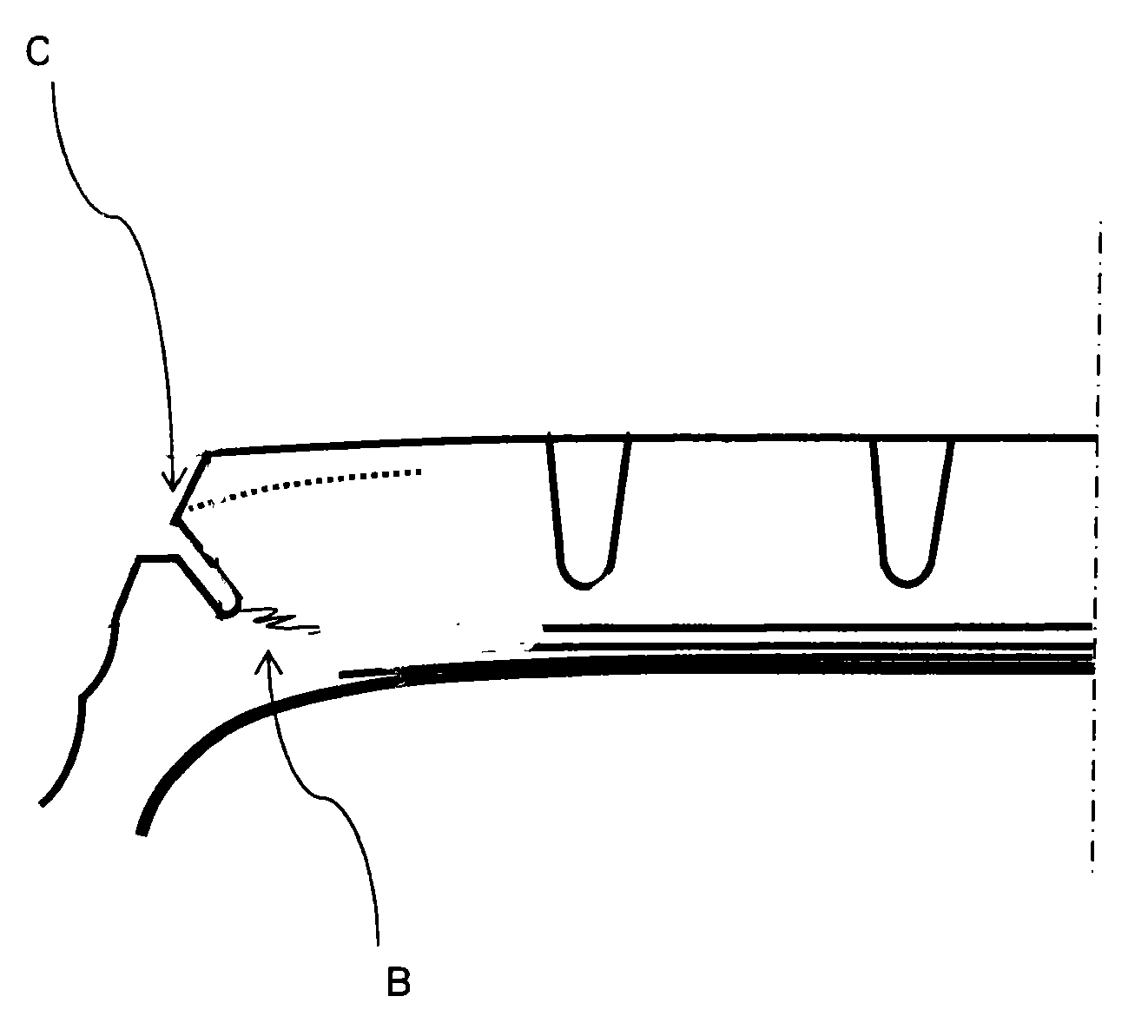

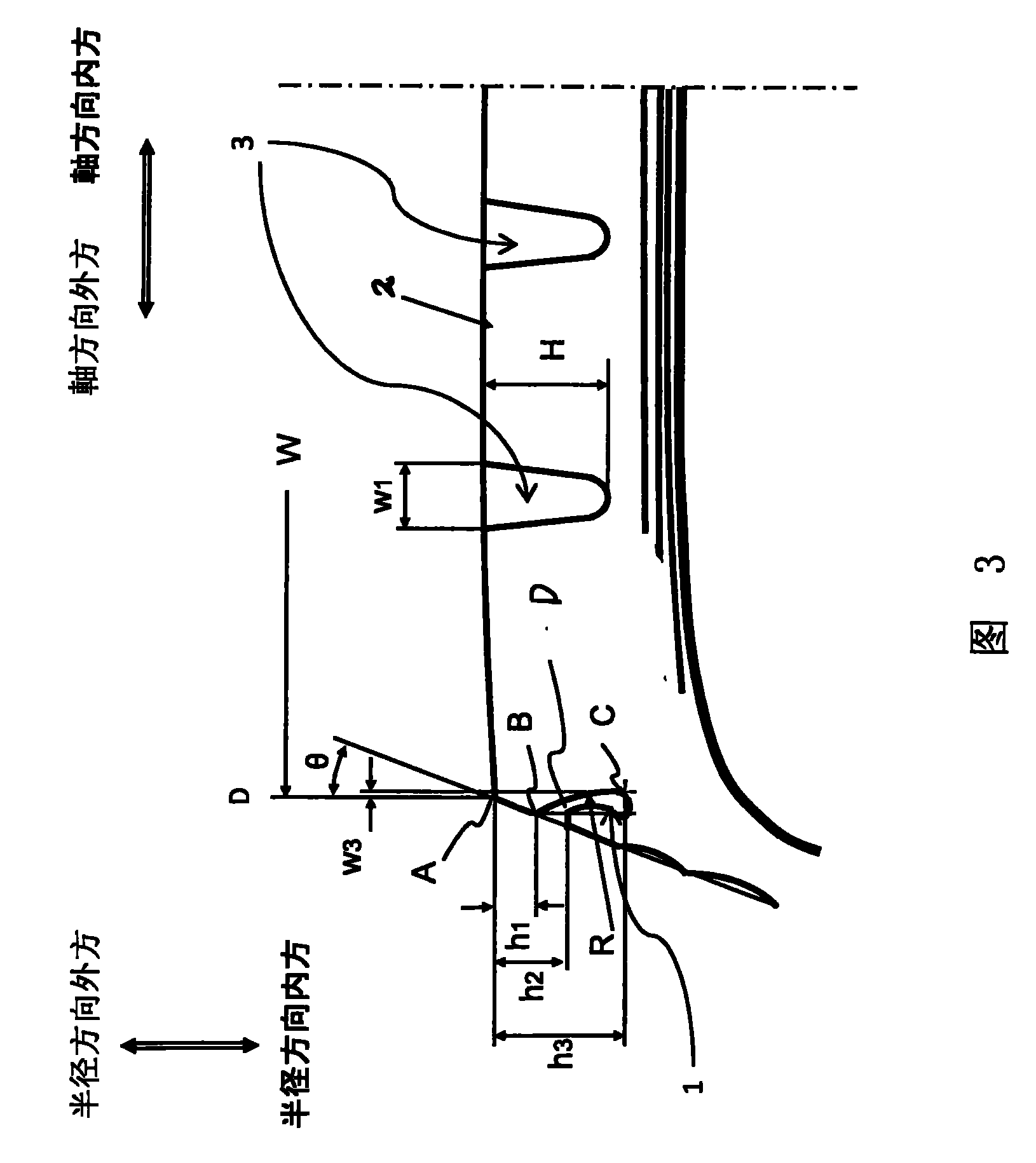

[0024] The load-bearing pneumatic all-steel wire radial tire involved in the present invention is at the crown position (such as image 3 The 2 parts shown) have several main grooves (such as image 3 The three parts shown) extend in the circumferential direction and have a running surface that is in contact with the road surface. For trucks and bus all-steel radial tires, at least one lateral side of the outer contour that is inclined from the crown end to the radially inward direction is arranged. In fact, it is an annular dish-shaped groove that is continuous in the circumferential direction and also continues inward in the radial direction (such as image 3 Part 1 shown), the annular dish-shaped groove is located from the end of the crown toward the radially inward, and the depth is the depth of the main groove (such as image 3 Within 20% to 160% of H) shown. The arc surface of the inner wall of the annular dish-shaped groove, the radius ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com