Pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire parts, tire treads/tread patterns, transportation and packaging, etc. It can solve the problems of deterioration of ground handling stability and low ground pressure, so as to improve handling stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

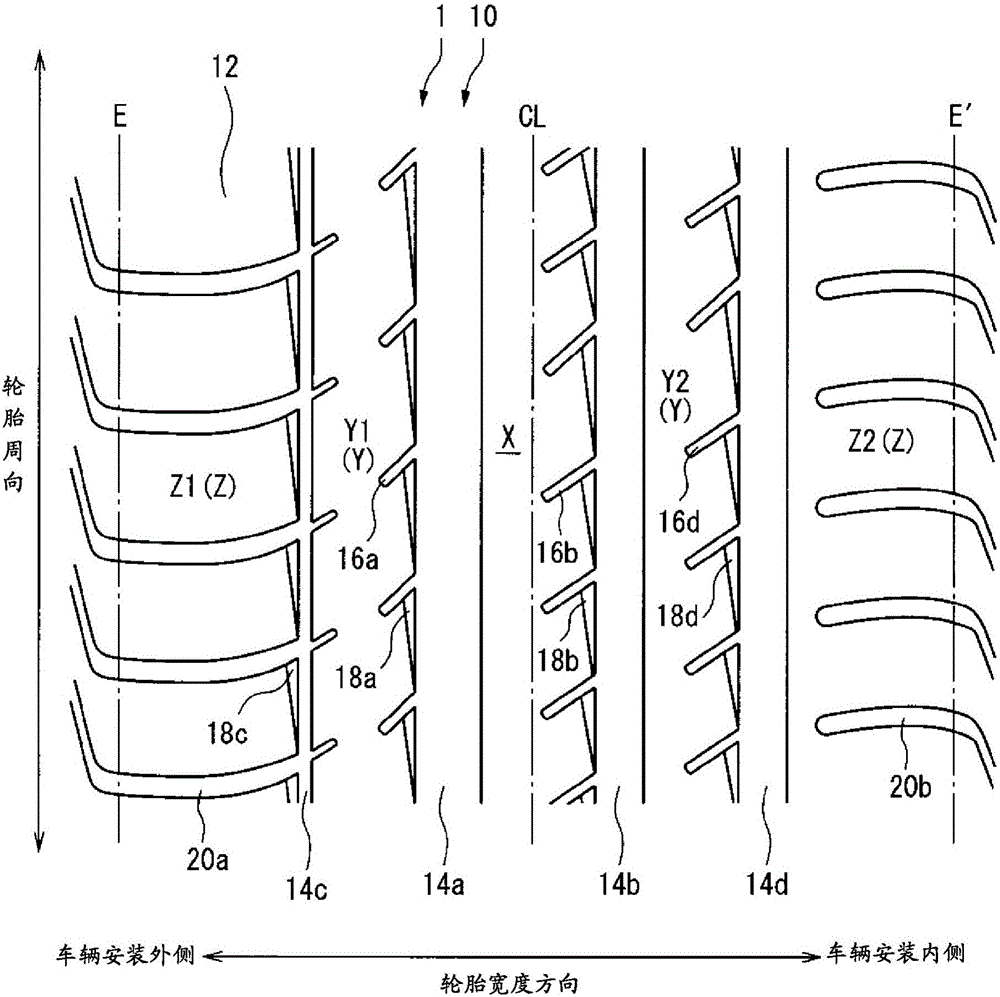

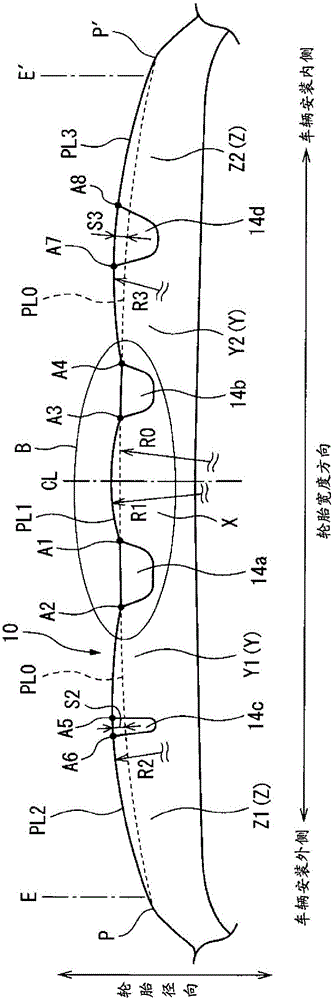

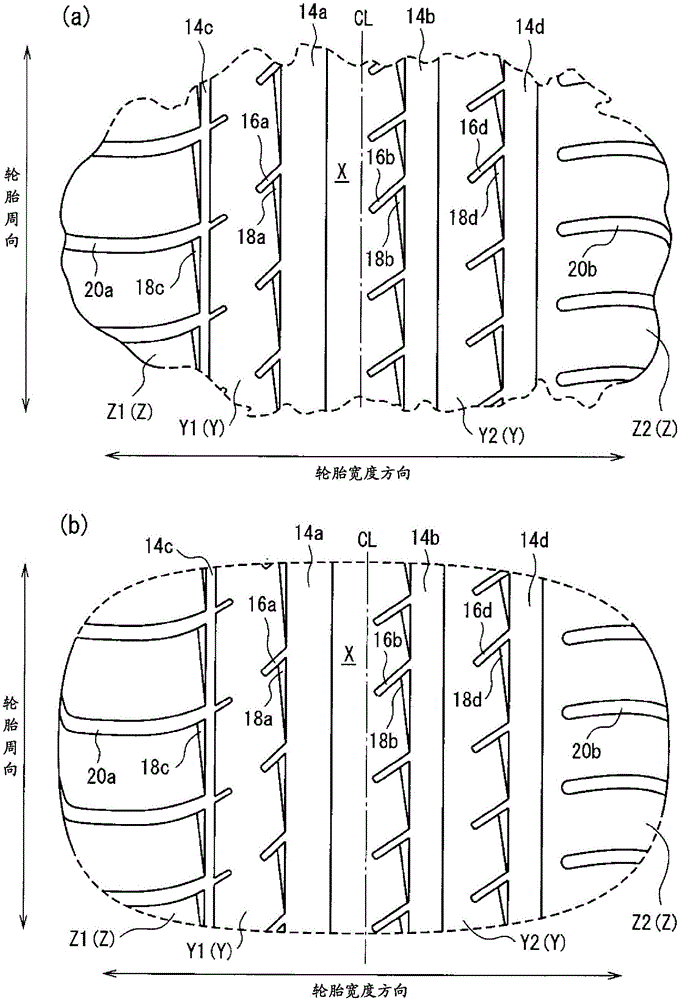

[0075] The tire size is 235 / 40ZR18 (95Y), which has the same figure 1 The tread pattern shown is an approximate tread pattern and has figure 2 ( Figure 4 ) of the tread surface contour lines PL1, PL2, PL3 of the pneumatic tires of Examples 1 to 6. In addition, the various conditions of the minute parts of the contour line of each tread surface of the pneumatic tires of Examples 1-6 are as shown in Table 1 below.

[0076] In contrast, the tire size was 235 / 40ZR18 (95Y), except figure 2 The pneumatic tire of the conventional example has the same structure as the pneumatic tire of Example 1 except that the contour lines PL1 , PL2 , and PL3 of the tread surface shown coincide with the reference contour line PL0 .

[0077] Each test tire of Example 1 to Example 6 and the conventional example produced in this way was assembled on a rim of 18×8.5J, and the air pressure was set to 230kPa, and it was mounted on a passenger car with a displacement of 2000cc. 1 (straight running p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com