Method for preparing multilayered lattice metal and foamed aluminium composite material

A composite material and aluminum foam technology, applied in the field of multi-layer lattice metal-aluminum foam composite material and its preparation, can solve the problems of poor energy dissipation performance, low structural rigidity and strength, and limit the application of foam core sandwich structure, etc., to achieve The effect of excellent overall performance and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

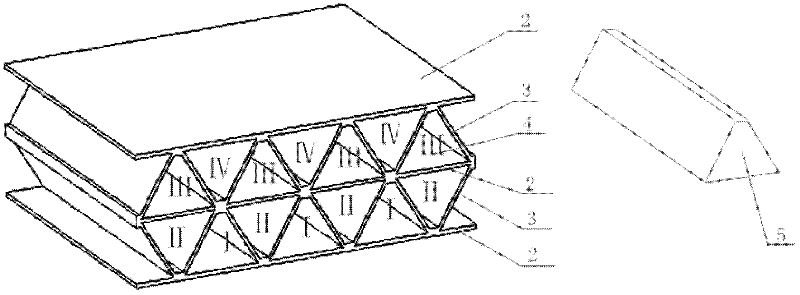

[0027] Embodiment 1: First, the corrugated core 3 is formed by molding and folding the flattened steel plate, then the corrugated core 3 and the panel 2 are cleaned to remove oil and rust, and the corrugated core is welded layer by layer by brazing or laser welding. Body 3 and panel 2 are welded to form 2 to 4 layers of corrugated structure lattice metal sandwich panels, wherein the corrugated structure core body of the corrugated structure lattice metal sandwich panel adopts the structural form of corrugated triangle vertices arranged in parallel (see figure 1 ); Then, according to the space size of the hole 4 in the corrugated structure core body 3, a cutting machine is used to cut the block aluminum foam into a triangular prism or a trapezoidal prism 5 adapted to the space size of the hole 4 in the corrugated structure core body 3; A layer of castor glue is evenly coated on the contact surface between the prism body and the core body of the corrugated structure, and then the...

Embodiment 2

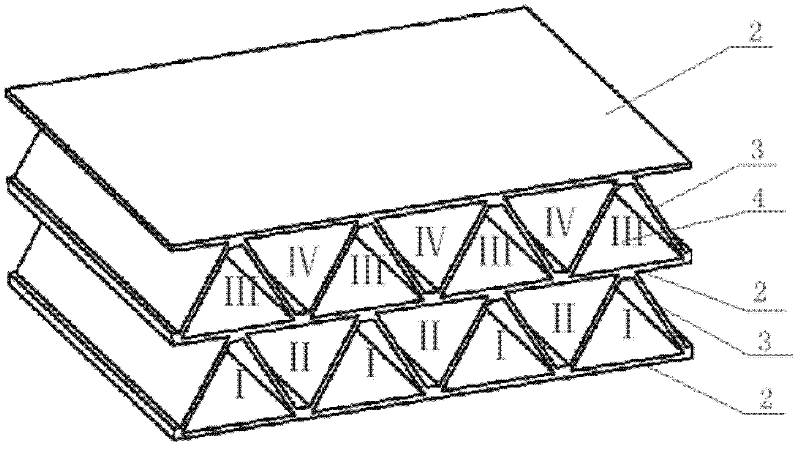

[0028] Embodiment 2: First, the corrugated core 3 is formed by molding and folding the flattened steel plate, and then the corrugated core 3 and the panel 2 are cleaned to remove oil and rust, and the corrugated core is welded layer by layer by brazing or laser welding. Body 3 and panel 2 are welded to form 2 to 4 layers of corrugated structure lattice metal sandwich panels, wherein the corrugated structure core body of the corrugated structure lattice metal sandwich panel adopts a structural form in which the vertices of triangles are arranged in parallel and staggered (see figure 2 ), then, according to the spatial size of the hole 4 in the corrugated structure core body 3, a cutting machine is used to cut the block aluminum foam into a triangular prism or a trapezoidal prism 5 adapted to the spatial size of the hole 4 in the corrugated structure core body 3; The contact surface between the prism and the corrugated structure core is evenly coated with a layer of castor glue,...

Embodiment 3

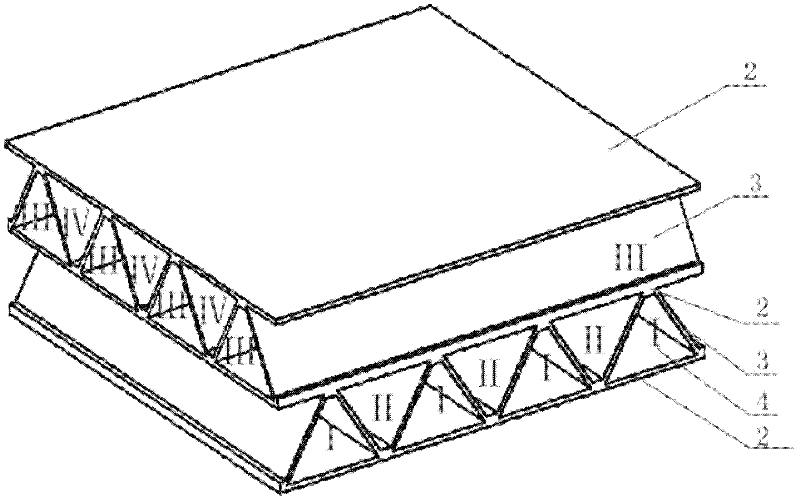

[0029] Embodiment 3: First, the corrugated core 3 is formed by molding and folding the flattened steel plate, then the corrugated core 3 and the panel 2 are cleaned to remove oil and rust, and the corrugated core is welded layer by layer by brazing or laser welding. The body 3 is welded with the panel 2 to form a 2-4-layer corrugated structure lattice metal sandwich panel, wherein the corrugated structure core body of the corrugated structure lattice metal sandwich panel adopts an orthogonal structure (see image 3 ); Then, according to the space size of the hole 4 in the corrugated structure core body 3, a cutting machine is used to cut the block aluminum foam into a triangular prism or a trapezoidal prism 5 adapted to the space size of the hole 4 in the corrugated structure core body 3; The contact surface between the prism body and the core body is uniformly coated with a layer of castor glue, and then the prism body is inserted into any layer of 2 to 4 layers of corrugated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com