Method for preparing grapheme reinforced aluminum matrix composite material

A technology for strengthening aluminum-based and composite materials, which is applied in the field of preparing graphene-reinforced aluminum-based composite materials, can solve problems such as easy agglomeration and poor graphene dispersibility, achieve uniform dispersion, improve tensile strength, and prevent graphene agglomeration phenomenon. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

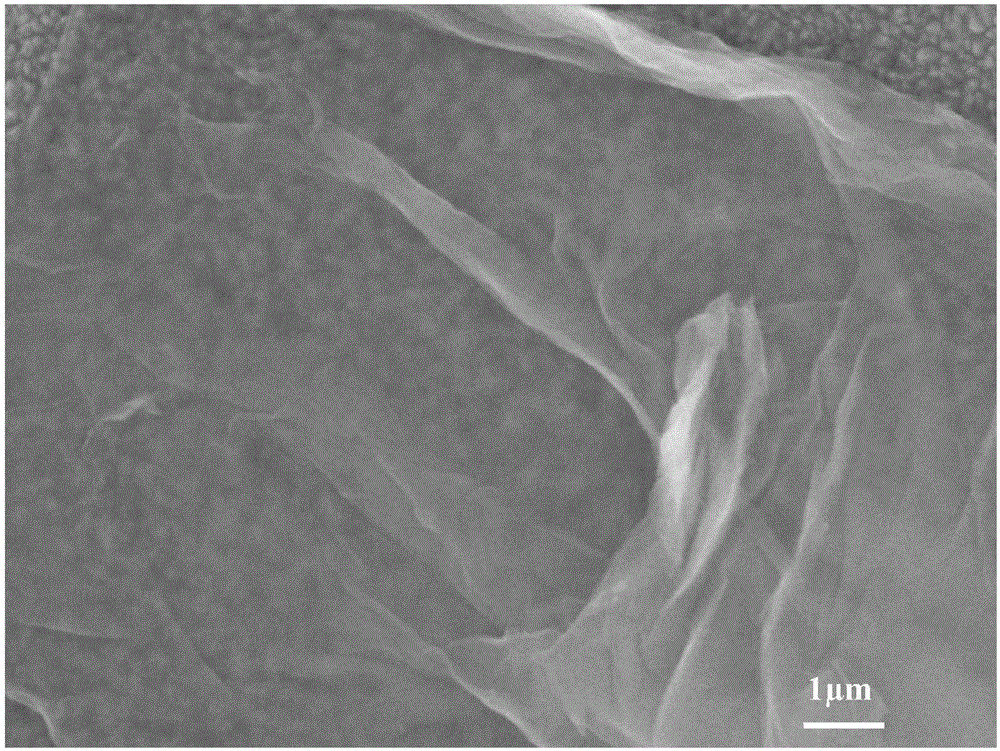

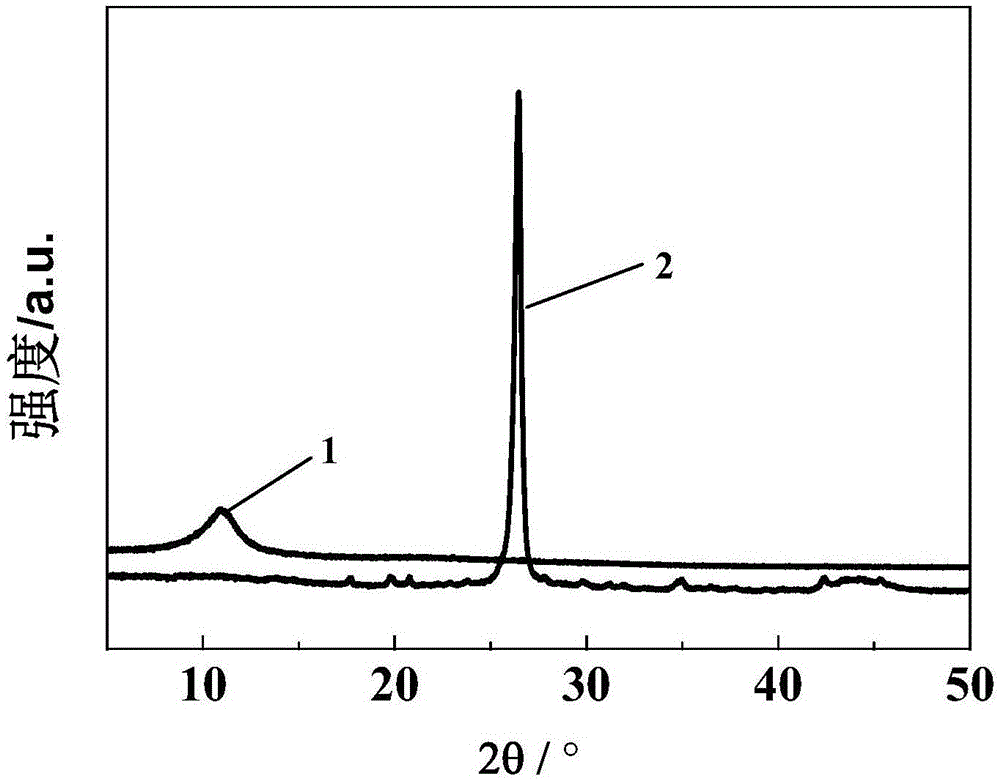

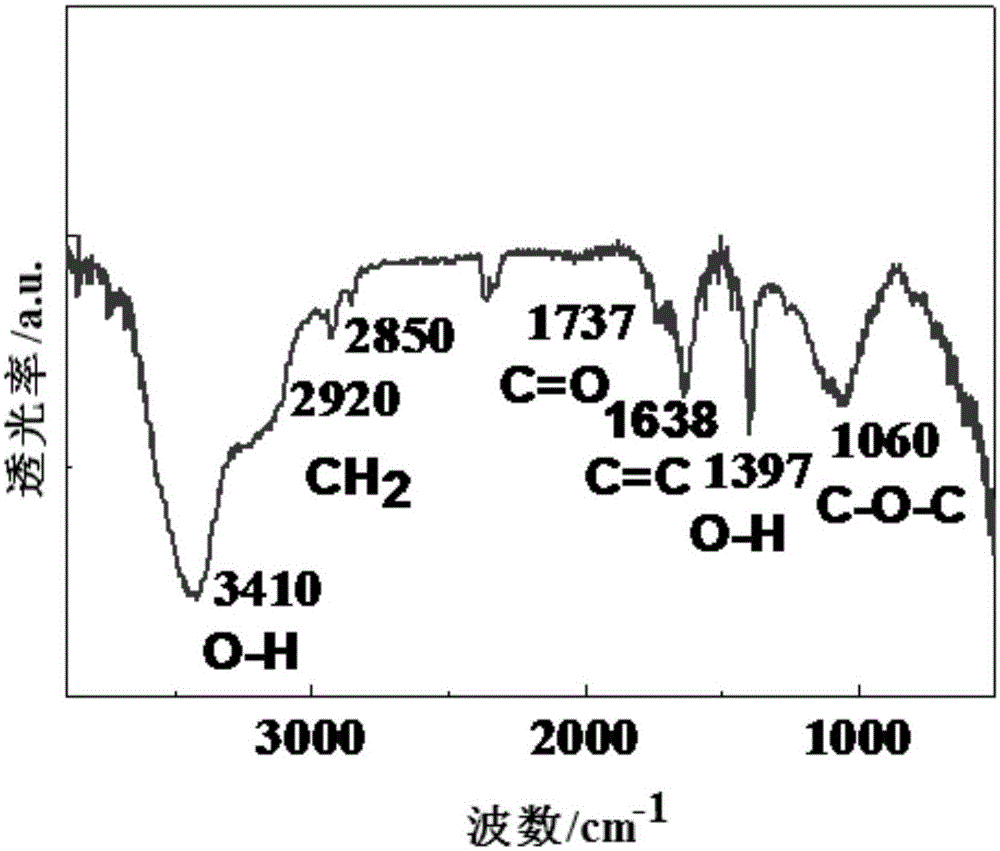

[0026] Specific embodiment one: this embodiment is a kind of method for preparing graphene-reinforced aluminum-based composite material, specifically according to the following steps:

[0027] 1. Preparation of graphene oxide: add 1g of graphite powder and 1g of sodium nitrate to the Erlenmeyer flask containing 46mL of concentrated sulfuric acid under the condition of ice-water bath, mix and stir for 20min under the condition of ice-water bath; Add 6g of potassium permanganate and stir for 40 minutes to obtain a green-purple mixed solution. Keep the green-purple mixed solution at a temperature of 30°C to 40°C for 1 hour, and then add it at a temperature of 30°C to 40°C. Incubate 40mL of distilled water at a temperature of 85°C to 95°C for 30 minutes to obtain a brown mixed solution. Add 100mL of distilled water and 6mL of hydrogen peroxide to the brown mixed solution at room temperature to obtain a bright yellow mixed solution. Then repeatedly wash the bright yellow mixed solu...

specific Embodiment approach 2

[0031] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mass concentration of the concentrated sulfuric acid described in step one is 98%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0032]Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the volume ratio of the weight of the aluminum powder described in step 2 to the CTAB solution with a mass fraction of 1% is 1g:1mL. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com