Graphene/aluminum composite cathode material of lithium ion battery and preparation method thereof

A technology of lithium ion battery and negative electrode material, applied in battery electrodes, circuits, electrical components, etc., can solve the problems affecting the application of graphene, and achieve the effect of easy implementation, wide promotion, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

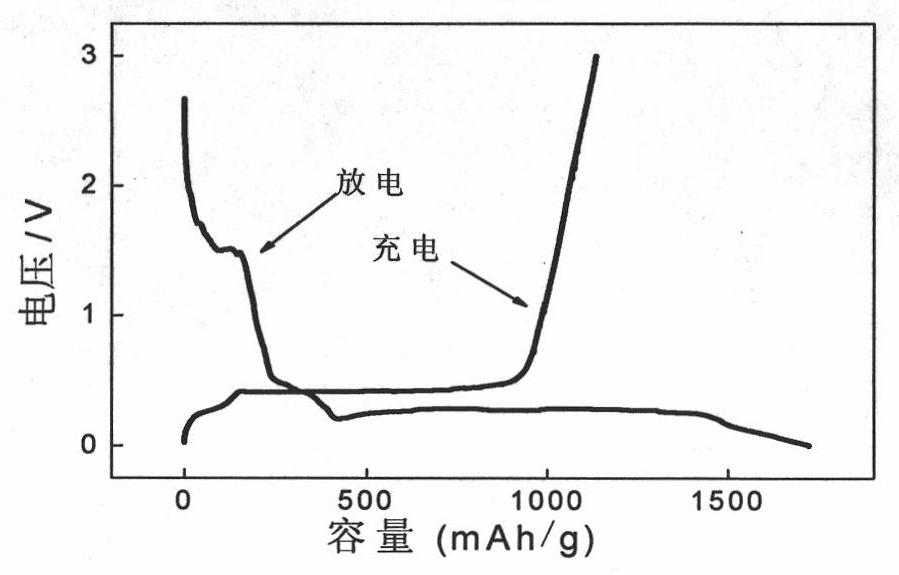

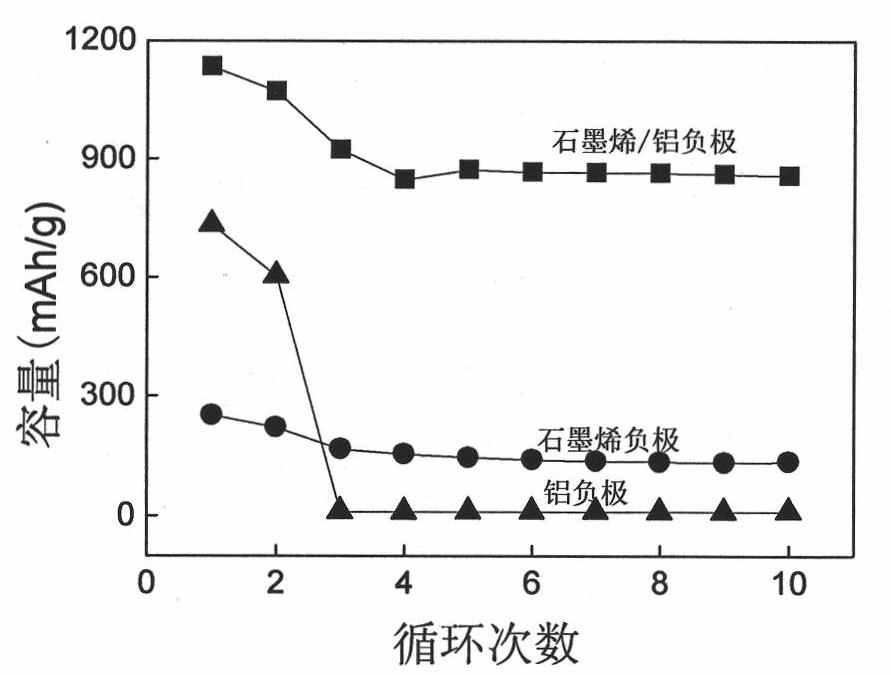

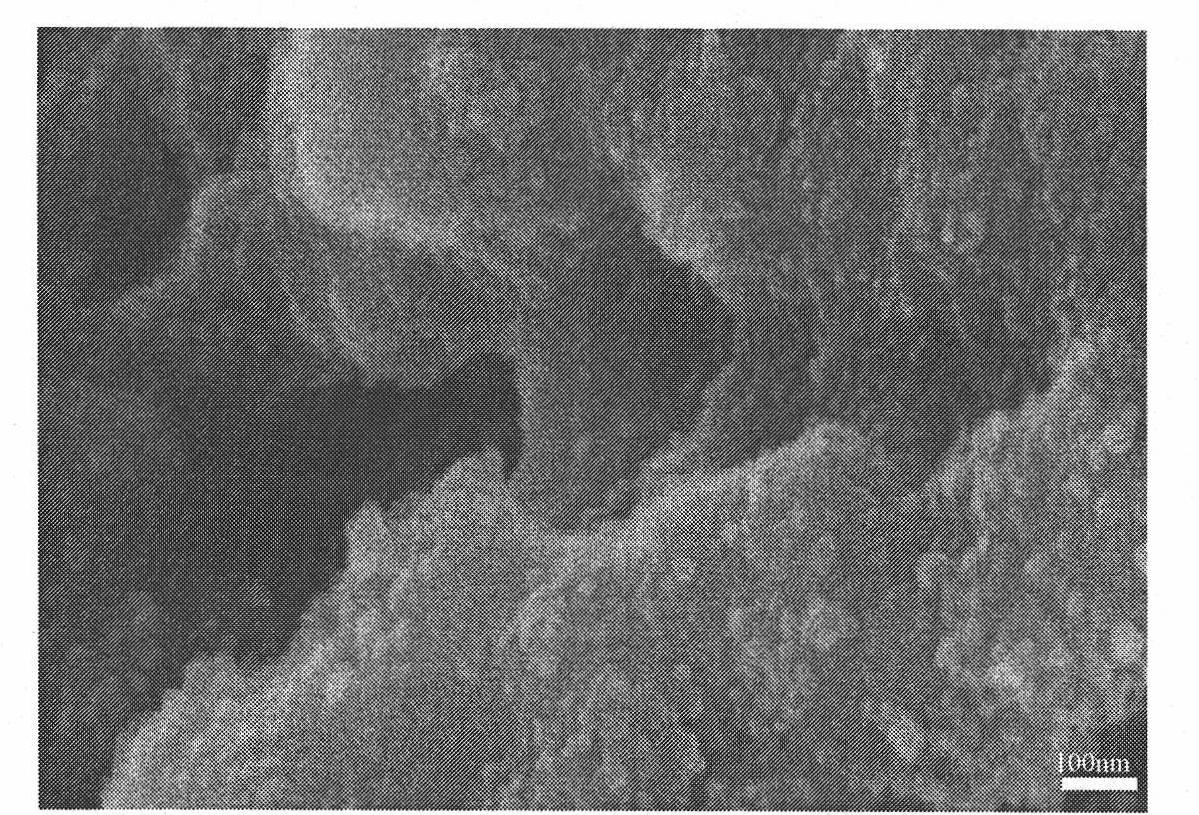

Image

Examples

Embodiment 1

[0014] Take by weighing Graphene 2g, aluminum powder 200mg, place in ball mill, after continuous ball milling 5h, obtain the fully mixed graphene / aluminum composite material; Take by weighing this composite material 540mg, concentration is 60% polytetrafluoroethylene (PTFE) Put 386mg of ethanol emulsion into a 100ml small beaker, then add 40ml of absolute ethanol to mix the above mixture evenly into a slurry, and when it is half-dried, press it on the copper foil current collector to make a negative electrode according to the battery plate manufacturing process Then place it in a vacuum drying oven and dry it at 150°C, use the lithium sheet as the positive electrode, and form a lithium-ion battery with the above materials, and charge and discharge the materials for 2 cycles of aging at a current density of 10mA / mg. The graphene / aluminum composite negative electrode material is obtained.

[0015] Preparation of the positive electrode of the lithium-ion battery: take the positiv...

Embodiment 2

[0018] Take by weighing Graphene 2g, aluminum powder 2g, place in agitator, after continuous stirring 1h, obtain the fully mixed graphene / aluminum composite material; Take by weighing this composite material 1.08g, concentration is 60% polytetrafluoroethylene (PTFE ) Ethanol emulsion 0.45g into a 100ml small beaker, then add 40ml of N-methyl-2-pyrrolidone to mix the above mixture evenly into a slurry, when it is baked to semi-dry according to the battery plate manufacturing process, press it on the copper The negative plate is made on the foil current collector, and then it is placed in a vacuum drying oven and dried at 100°C. The lithium sheet is used as the positive electrode to form a lithium-ion battery with the above materials, and the materials are tested at a current density of 100mA / mg. After one cycle of charging and discharging, the graphene / aluminum composite negative electrode material was obtained.

[0019] Preparation of the positive electrode of the lithium-ion ...

Embodiment 3

[0022] Take by weighing Graphene 2g, aluminum powder 6g, place in ball mill, after continuous ball milling 3h, obtain the fully mixed graphene / aluminum composite material; Take by weighing this composite material 540mg, concentration is 60% polytetrafluoroethylene (PTFE) Put 100mg of ethanol emulsion into a 100ml small beaker, then add 30ml of N-methyl-2-pyrrolidone to mix the above mixture evenly into a slurry, and when it is half-dried, press it on the copper foil set Make a negative plate on the fluid, then place it in a vacuum drying oven and dry it at 100°C, use a lithium sheet as the positive electrode, and form a lithium-ion battery with the above materials, and charge and discharge one at a current density of 30mA / mg cycle, charge and discharge the graphene / aluminum material to obtain a graphene / aluminum composite negative electrode material.

[0023] The counter electrode of the lithium-ion battery is a lithium sheet;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com