Light packaging member of power machine with high heat transfer efficiency

A technology of high thermal conductivity and power devices, which is applied in semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve the problems of reducing chip thermal stress, deformation movement, high interface thermal resistance, etc., to reduce thermal stress, Effects of improved heat dissipation performance, reliability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

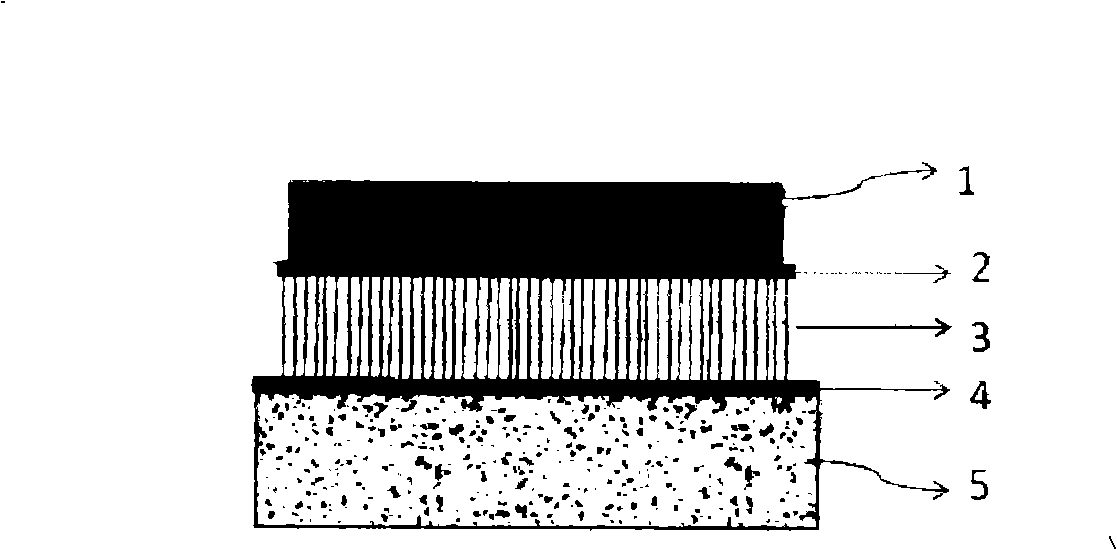

[0013] See attached figure 1 , consisting of an upper high thermal conductivity bonding interface layer 2 , a heat sink film 3 , a lower high thermal conductivity bonding interface layer 4 , and a heat dissipation substrate 5 sequentially bonded on the back of the chip 1 from top to bottom, wherein,

[0014] Bonding interface layers 2 and 4 are metals and their alloy materials with good thermal and electrical conductivity, including Sn, In, Zn, Au, Ag, Cu, Ti, Ni, Al, Mo and their alloys such as CuIn, AgIn, AuIn, InSn , AgSn, AuSn, etc., the above-mentioned bonding interface layer is prepared by magnetron sputtering, evaporation, chemical deposition and other methods; the bonding interface layer 2 and 4 are relatively thin, with a thickness of about 10-100 nanometers, have high thermal conductivity, and are easy to chip 1 is welded with the heat sink film 3 .

[0015] The heat sink film 3 is made of lightweight materials with highly directional thermal conductivity, and mater...

Embodiment 2

[0019] The material of the bonding interface layer 4 in Example 1 is selected from metal thin films including Fe or Co or Ni or Cu or Pd or Ti or Mo materials, with a thickness of 5-50 nanometers. The bonding interface layer 4 can be directly prepared on the surface of the heat dissipation substrate 5 by methods such as sputtering, electroplating, electroless plating, and electron beam evaporation, and then the heat sink film 3 can be directly grown, including conductive and high thermal conductivity carbon nanotube films, carbon nanofiber films, etc. Material. The heat sink film 3 is mainly prepared by methods such as hot wire chemical vapor deposition, plasma chemical vapor deposition or arc plasma deposition, wherein the thermal conductivity of the aligned carbon nanotubes is 600-2000W / m*K, which has a good conductivity.

[0020] The material process of the heat dissipation substrate 5 is the same as that of the first embodiment.

[0021] In this example, the bonding inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com