Rated voltage of 35kv or below shallow sea wind farm photoelectrical transmission composite cable

A technology for wind farms and photoelectric transmission, which is applied in the directions of submarine cables, insulated cables, communication cables, etc., can solve the problem of increasing manufacturing costs, increasing laying costs and laying difficulties, and the mechanical strength of cables, wear resistance, corrosion resistance, and waterproof performance are difficult to adapt to. and other problems, to achieve the effect of convenient installation, good waterproof performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

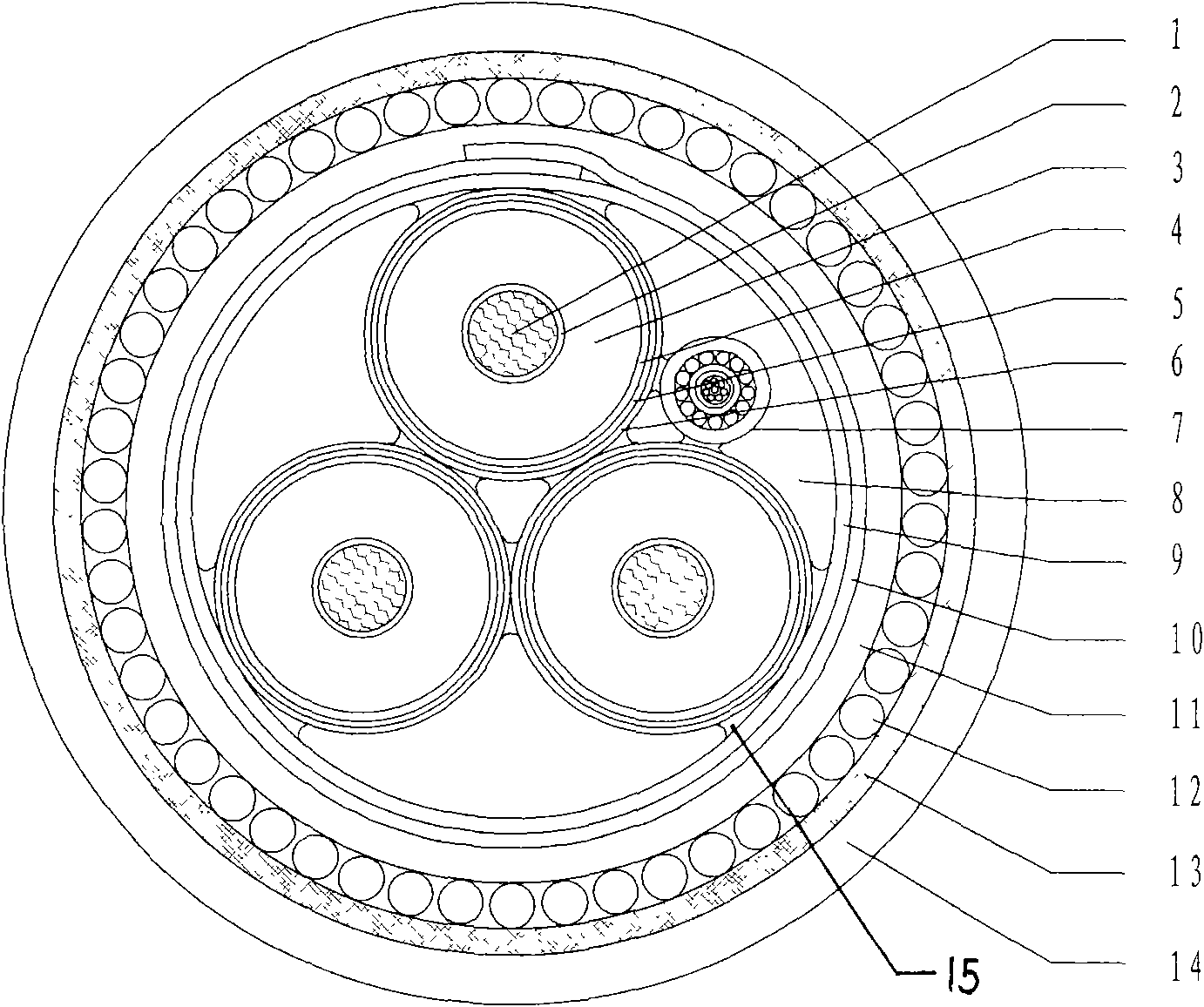

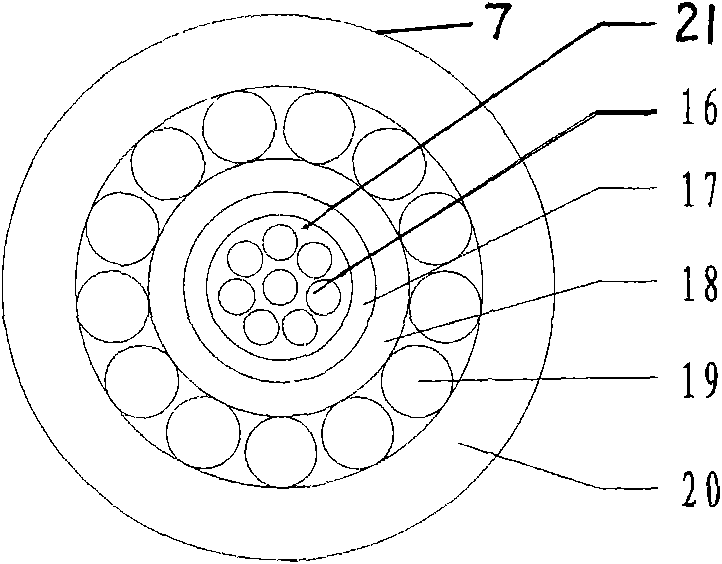

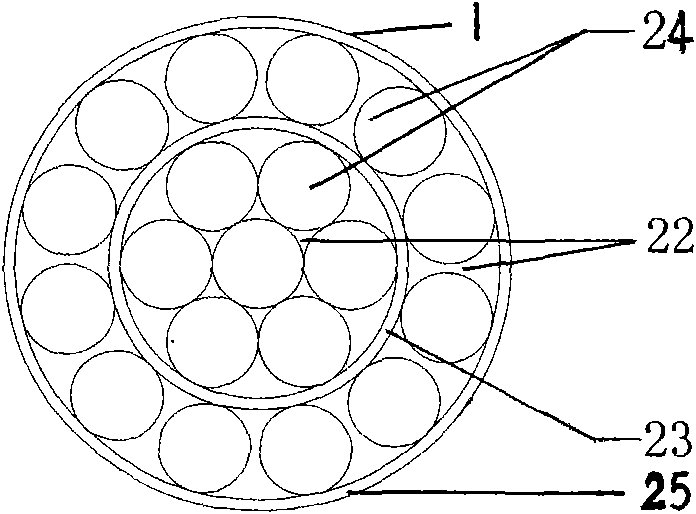

[0010] refer to figure 1 , figure 2 , image 3 Firstly, the conductor 1 is made: multiple strands of copper wires 24 coated with water-blocking oil paste 22 are stranded to form the central layer of the conductor 1, and then the central layer is covered with a semi-conductive resistance water tape layer 23, and then coated with multiple strands of resistive oil. The copper wire 24 of the water-oil paste 22 is coated on the outside of the semiconductive resistance water tape layer 23 of the central layer, and then coated with the outer semiconductive resistance water tape layer 25 to form the conductor 1 . Make optical fiber communication unit 7 again: outside the loose tube 17 made of stainless steel tube with optical fiber 16 and fiber paste 21 inside, cover the inner sheath 18 made of high-density polyethylene and the armored layer 19 made of phosphating steel wire successively 1. The outer sheath 20 made of high-density anti-corrosion polyethylene is made into the optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com