Preparation method for nano-Y-shaped molecular sieve/amorphous silicon-aluminum composite material

A technology of amorphous silicon aluminum and composite materials, which is applied in the field of preparation of molecular sieve composite materials, can solve problems such as complex process, long time, and additional auxiliary equipment, and achieve the goal of increasing product yield, increasing product yield, and improving selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

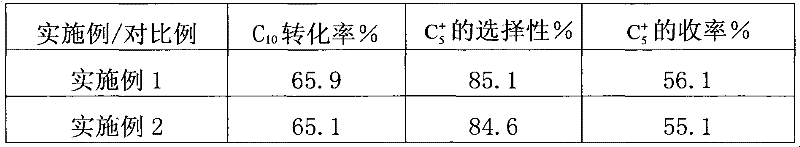

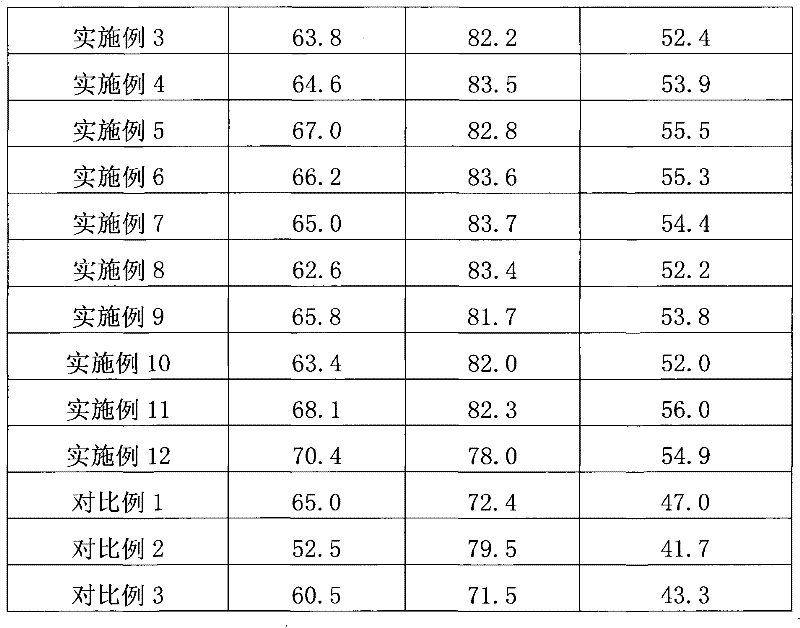

Examples

Embodiment 1

[0035] Example 1: Preparation method of Y-type molecular sieve / amorphous silicon-aluminum composite material.

[0036] (1) Synthetic guiding agent: use water glass as the silicon source and sodium metaaluminate as the aluminum source. Take 48g of water glass (modulus 3.0), add 8g of polyethylene glycol PEG-2000, stir at 15°C at a stirring speed of 200 rpm for 1 hour to obtain solution A; dissolve 7.8g of sodium hydroxide in 24mL Add 1.6 g of sodium metaaluminate to the water, and stir until the sodium metaaluminate is completely dissolved to obtain solution B; stir solution A at a stirring speed of 3000 rpm, pour solution B into solution A, and continue to stir at 3000 rpm Stir for 1.5 hours at a stirring speed of 200 rpm at 15°C and age for 12 hours at a stirring speed of 200 rpm. . Except surfactant, the molar ratio of other components is 0.04PEG-200:18Na 2 O:Al 2 o 3 : 22SiO 2 : 426H 2 O, the surfactant accounts for 7.3% of the total weight of the directing agent (in...

Embodiment 2

[0041] (1) Synthesis of guiding agent: take 42g of water glass (modulus 3.0), add 10g of Tween-20, and stir for 1 hour at 15°C with a stirring speed of 200 rpm to obtain solution A; oxidize 7.8g of hydrogen Dissolve sodium in 24mL of water, then add 1.6g of sodium metaaluminate, and stir until the sodium metaaluminate is completely dissolved to obtain solution B; stir solution A at a stirring speed of 3000 rpm, and pour solution B into solution A , continue to stir at a stirring speed of 3000 rpm for 1.5 hours, and finally stir and age at a stirring speed of 200 rpm at 15°C for 12 hours, add 18 mL of water after aging, and continue to stir at a stirring speed of 200 rpm at 15°C Stir for 0.5 hours. Except surfactant, the molar ratio of other components is _18Na 2 O:Al 2 o 3 : 20SiO2 2 : 380H 2 O, surfactant accounts for 9.7% of total weight (containing surfactant). Set aside for 15 hours.

[0042] (2) Synthesis of nanometer Y-type molecular sieve: Dissolve 3g of sodium h...

Embodiment 3

[0046] (1) Synthesis of guiding agent: take 36g of water glass (modulus 3.0), add 5g of polypropylene glycol-1000, and stir for 1 hour at 15°C with a stirring speed of 200 rpm to obtain solution A; oxidize 5.4g of hydrogen Dissolve sodium in 24mL of water, then add 1.6g of sodium metaaluminate, and stir until the sodium metaaluminate is completely dissolved to obtain solution B; stir solution A at a stirring speed of 3000 rpm, and pour solution B into solution A , continue to stir at a stirring speed of 3000 rpm for 1.5 hours, and finally stir and age at a stirring speed of 200 rpm at 15°C for 12 hours, add 20.4mL of water after aging, and continue to stir at 200 rpm at 15°C Stir at high speed for 0.5 hours. Except surfactant, the molar ratio of other components is 15Na 2 O:Al 2 o 3 : 18SiO 2 : 360H 2 O, the surfactant accounts for 5.4% of the total weight of the directing agent (including the surfactant). Set aside for 12 hours.

[0047] (2) Synthesis of nano Y-type mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com