Electronic device and circuit board assembly thereof

A technology of circuit board components and substrates, applied in the direction of electrical equipment construction parts, circuit heat parts, printed circuit parts, etc., can solve the problem of limited heat dissipation area, increase heat dissipation area, realize heat conduction, and improve heat dissipation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

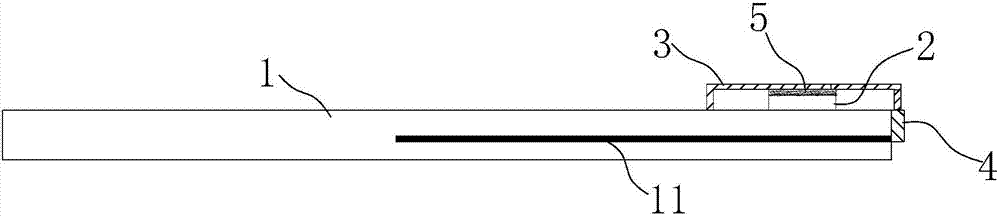

[0026] See figure 1 , this embodiment provides a circuit board assembly, including a substrate 1 , a heating element 2 , a shield 3 and a heat conducting member 4 .

[0027] The heating element 2 is arranged on the surface of the substrate 1, the shielding cover 3 is fixed on the surface of the substrate 1, and the heating element 2 is covered, and a thermal conductive glue 5 is connected between the heating element 2 and the shielding cover 3, and the inside of the substrate 1 has a layer metal layer 11. The shielding cover 3 is bonded to the metal layer 11 inside the substrate 1 through the heat conducting member 4 to realize heat conduction. Wherein, the way of heat conduction in this embodiment may be that the two surfaces are closely attached to each other, or the two may be bonded by a thermally conductive adhesive material.

[0028] Specifically, the thermally conductive adhesive 5 is pasted on the top surface of the heating element 2 , and the top of the thermally co...

Embodiment 2

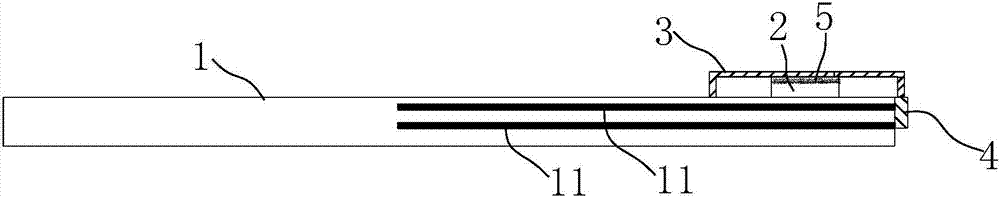

[0033] See image 3 The difference between this embodiment and Embodiment 1 is that two layers of metal layers 11 spaced up and down are arranged inside the substrate 1 of this embodiment, and the sides of the two layers of metal layers 11 are exposed to the side of the substrate 1, and are fixed to the The heat conducting element 4 on the side of the substrate 1 is bonded. Compared with the first embodiment, the heat conduction element 4 of this embodiment is attached to more metal layers 11 , so that the heat can be dispersed to a larger area, and the heat dissipation rate can be further improved.

Embodiment 3

[0035] The difference between this embodiment and Embodiment 1 is that a hole 12 is opened on the substrate 1, and the heat conduction element 4 is embedded in the hole 12. One end of the heat conduction element 4 is attached to the shielding cover 2, and the other end is attached to the metal Layer 11 fits.

[0036] Specifically, this embodiment provides three implementation forms of the above structure:

[0037] For the first form of implementation see Figure 4 , the top of the heat conducting element 4 is attached to the bottom of the shielding case 3 , and the heat conducting adhesive 5 is bonded between the top of the heating element 2 and the top wall of the shielding case 3 .

[0038] For the second implementation form, please refer to Figure 5 , the top of the heat conducting member 4 is attached to the bottom of the shielding case 3 , and the heat conducting adhesive 5 is bonded between the outer side of the heating element 2 and the inner side of the shielding ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com