One-way heat conduction special copper tube and preparation method thereof

A copper tube, one-way technology, applied in the field of one-way heat conduction special copper tube and its preparation, can solve the problems of poor heat conduction directivity, overheating of parts to be radiated, easy excessive heat dissipation, etc., and achieve the effect of improved thermal conductivity and good heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

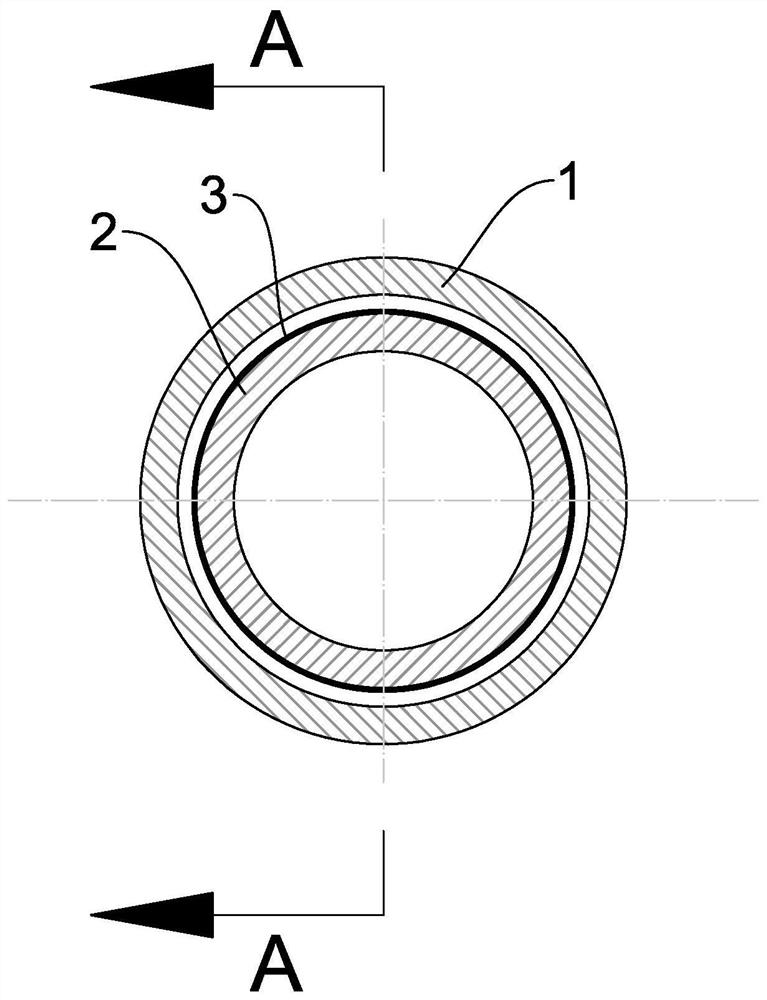

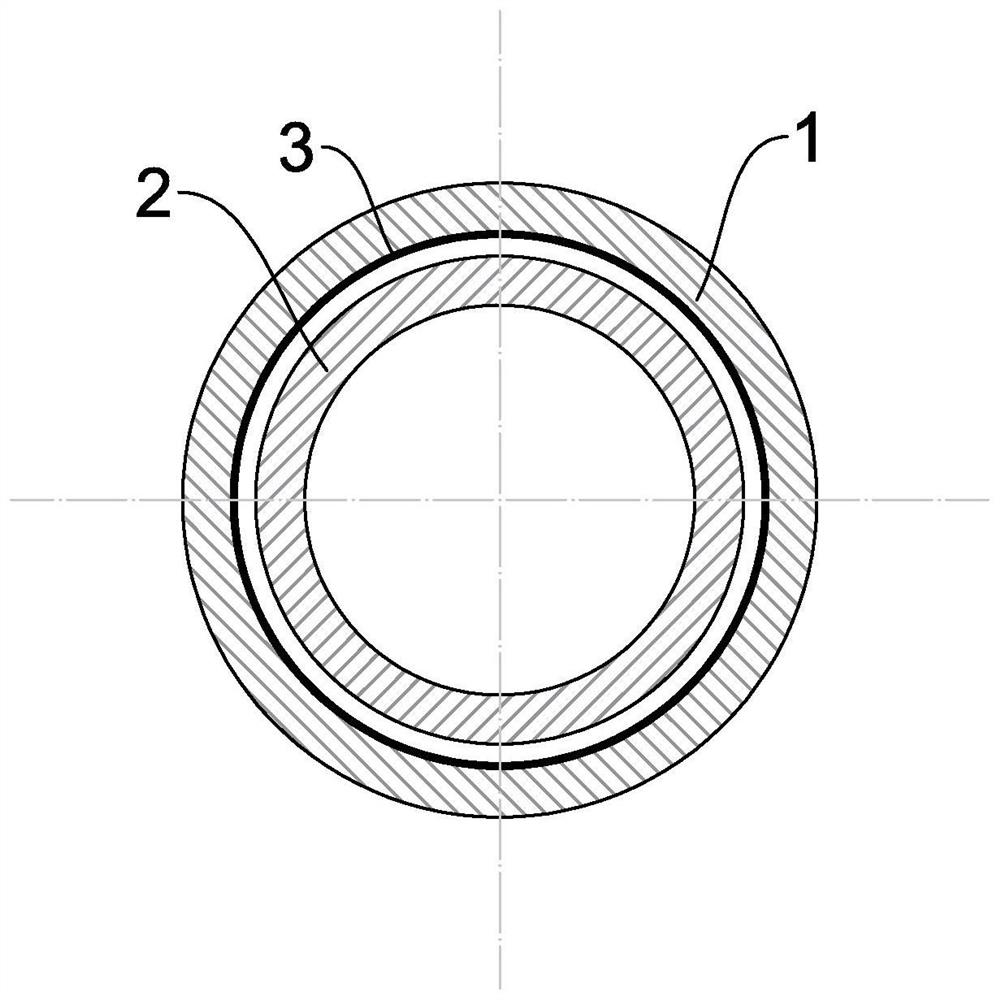

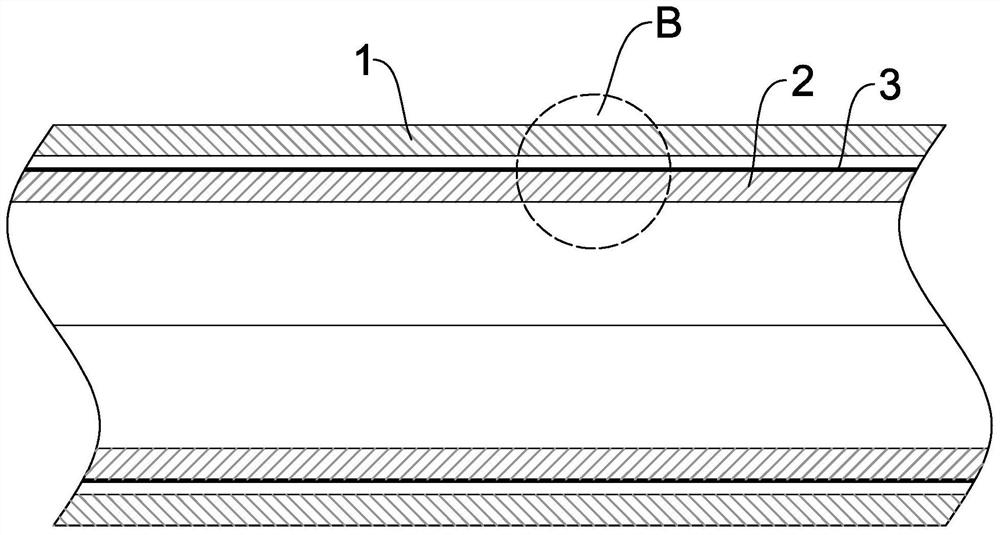

[0063] Prepare the polymer vesicle layer 3 on the outer wall of the inner copper tube 2:

[0064] 1) Select the outer wall of the inner copper tube 2 as the object covered with the polymer vesicle layer 3, which is recorded as the substrate reaction surface;

[0065] 2) Pretreatment of the reaction surface of the substrate, the pretreatment process is: degreasing, descaling, cleaning and drying of the reaction surface of the substrate;

[0066] Then it is subjected to template treatment, and the template treatment process is as follows: the inner wall of the inner copper tube 2 is coated with a layer of anti-acid film, placed in 1wt% dilute nitric acid solution for 30 seconds, taken out and cleaned, and then placed in ammonia gas Treat at 110°C for 2 hours in the atmosphere;

[0067] 3) Prepare a dichloromethane solution of saturated polystyrene-poly(ethylene-r-butylene)-polystyrene block copolymer, the saturated polystyrene-poly(ethylene-r-butylene)-polystyrene The dichloro...

Embodiment 2

[0079] Prepare the polymer vesicle layer 3 on the outer wall of the inner copper tube 2:

[0080] 1) Select the outer wall of the inner copper tube 2 as the object covered with the polymer vesicle layer 3, which is recorded as the substrate reaction surface;

[0081] 2) Pretreatment of the reaction surface of the substrate, the pretreatment process is: degreasing, descaling, cleaning and drying of the reaction surface of the substrate;

[0082] Then it is templated. The templating process is as follows: Potential activation is performed on the reaction surface of the substrate, an insulating polymer film is attached to the inner wall of the inner copper tube 2, the inner copper tube 2 is used as an electrode, and graphite is used as a counter electrode. Conduct electrodeposition activation in copper sulfate electrolyte, the activation current density is 10mA / cm 2 , the activation time is 2 minutes;

[0083] 3) Prepare a saturated polystyrene-poly4-vinylpyridine block copolym...

Embodiment 3

[0094] Prepare the polymer vesicle layer 3 on the inner wall of the outer copper tube 1:

[0095] 1) Select the inner wall of the outer copper tube 1 as the object covered with the polymer vesicle layer 3, which is recorded as the substrate reaction surface;

[0096] 2) Pretreatment of the reaction surface of the substrate, the pretreatment process is: degreasing, descaling, cleaning and drying of the reaction surface of the substrate;

[0097] Then it is templated. The templating process is as follows: a commercially available AAO film with a pore size of 400nm (AAO template) is used as a template for preparing a copper film, and the copper film is prepared by a secondary replica method, and the copper film is transferred through a scotch tape. And attach the copper film to the inner wall of the outer copper tube 1, carefully peel off the scotch tape, and then heat-treat at 500°C for 5 hours to complete the templating treatment and form a pre-template on the reaction surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com