Pulverizer

A crusher and material crushing technology, which is applied in the direction of grain processing, etc., can solve the problems that the heat conduction loss cannot be completely eliminated, and the temperature adjustment of the inner lining board cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

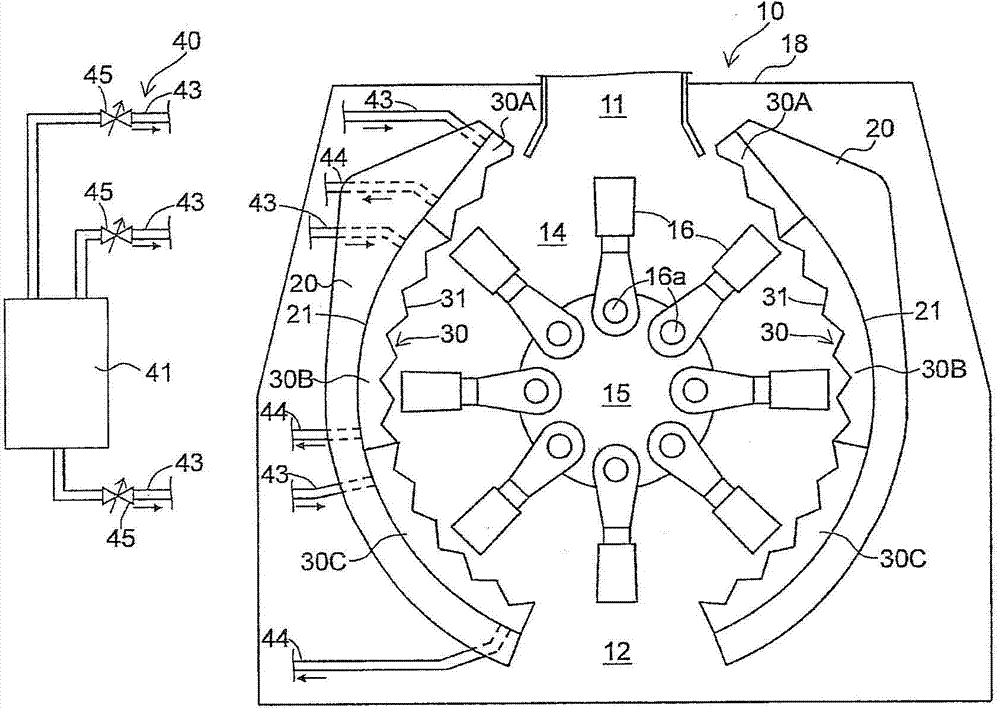

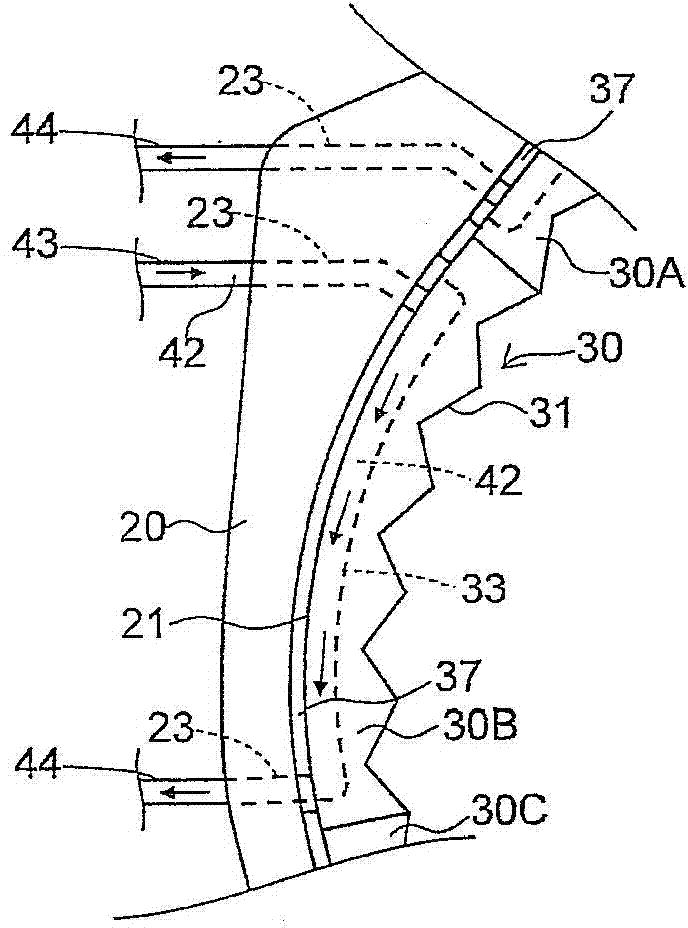

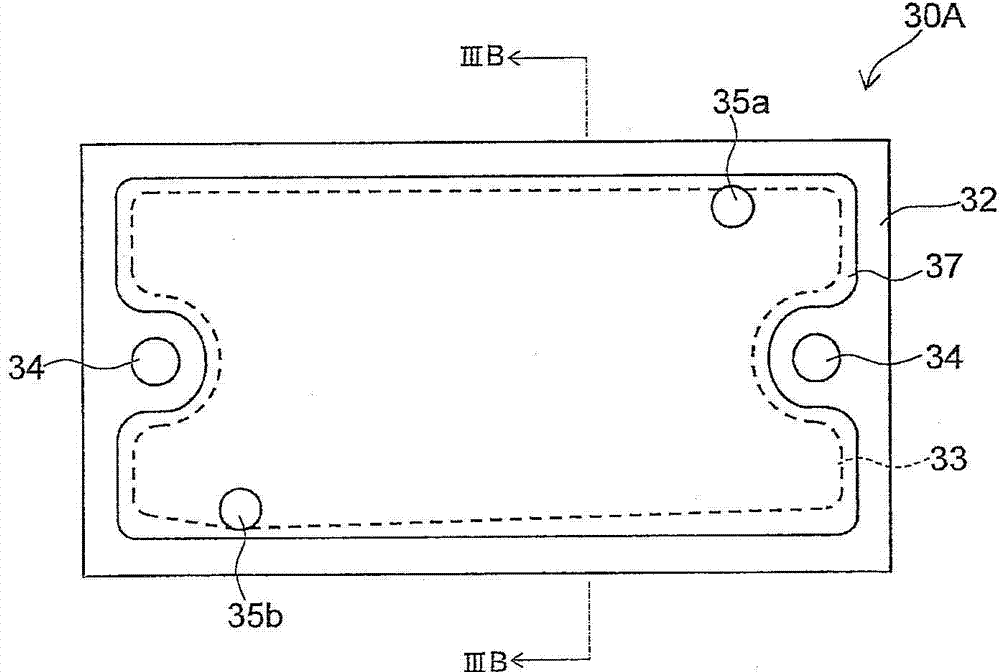

[0047] Refer below Figures 1 to 5C A crusher according to one embodiment of the present invention will be described.

[0048] figure 1 It is a front view showing the crusher 10 . again, in figure 1 shows a cross section when the crusher 10 is cut with a plane perpendicular to the axial direction of the rotor of the crusher 10 . The crusher 10 crushes the material by impacting the material thrown into the crushing space 14 inside the housing 18 from the inlet 11 formed in the housing 18 . The crushed material is discharged from the discharge port 12.

[0049] The crusher 10 includes a rotor 15 and a plurality of impact members 16 attached to the rotor 15 in a crushing space 14 inside a casing 18 . The impact members 16 are mounted on the rotor 15 at regular intervals along the circumferential direction of the rotor 15 . As the impact member 16, for example, a hammer is used. Such as figure 1 As shown, each percussion member 16 can also be mounted to the rotor 15 via a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com