Thermally and/or mechanically actuated component wall of a fluid and/or gas-conveying component, in particular a cylinder head of a combustion engine

A mechanical load, internal combustion engine technology applied in the field of component walls to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

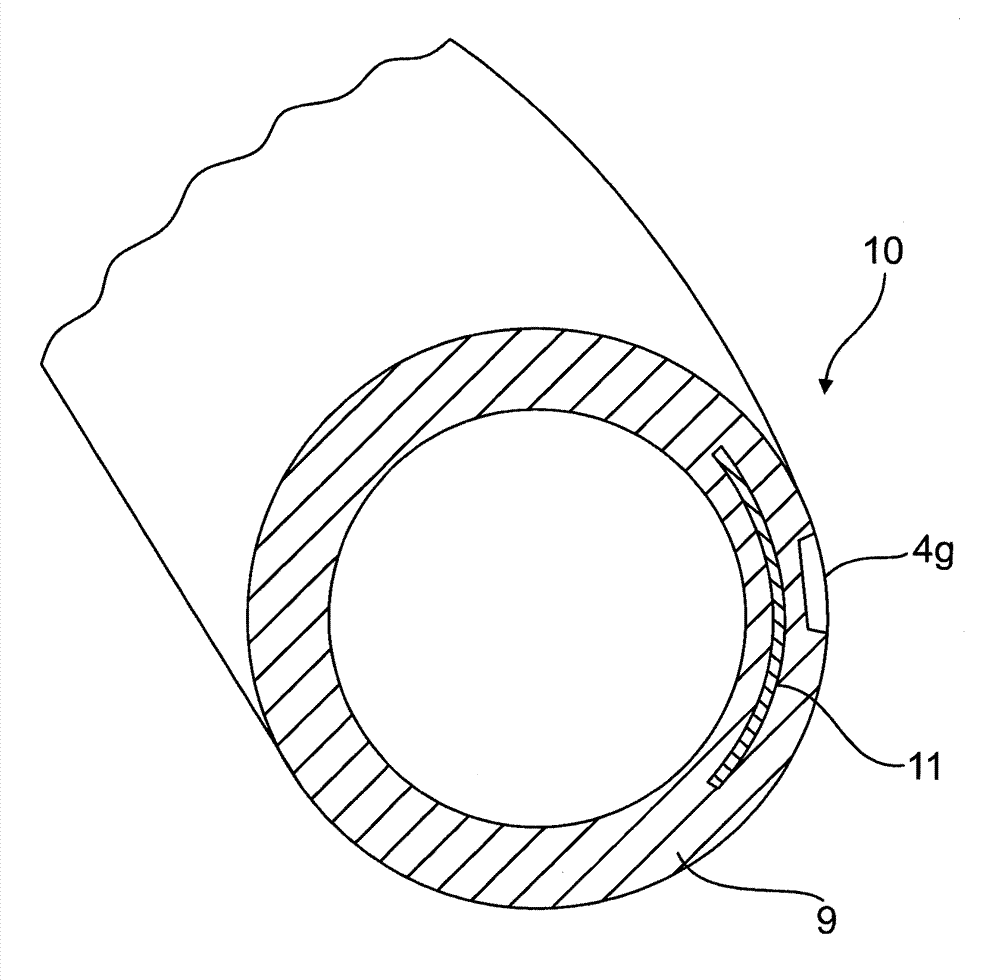

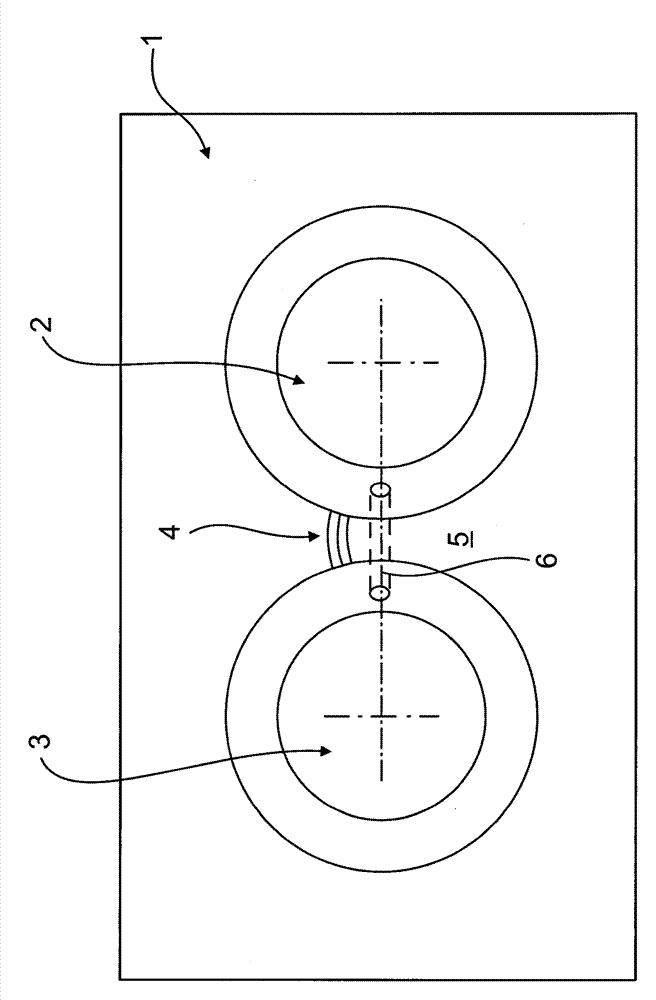

[0042] exist figure 1 A plan view of a partial area of a cylinder head 1 of an internal combustion engine is shown in the area of two adjacent valve seats 2 , 3 . As a crack initiation, a notch 4 is provided on the upper side of the bridging wall 5 , wherein the notch 4 is shifted a little relative to the smallest valve seat distance. Bore 6 runs as a crack stop parallel to the bridge wall surface in bridge wall 5 as connection of valve seats 2 , 3 below the cutout. For better visibility, the valve seats in all figures are shown without seat rings.

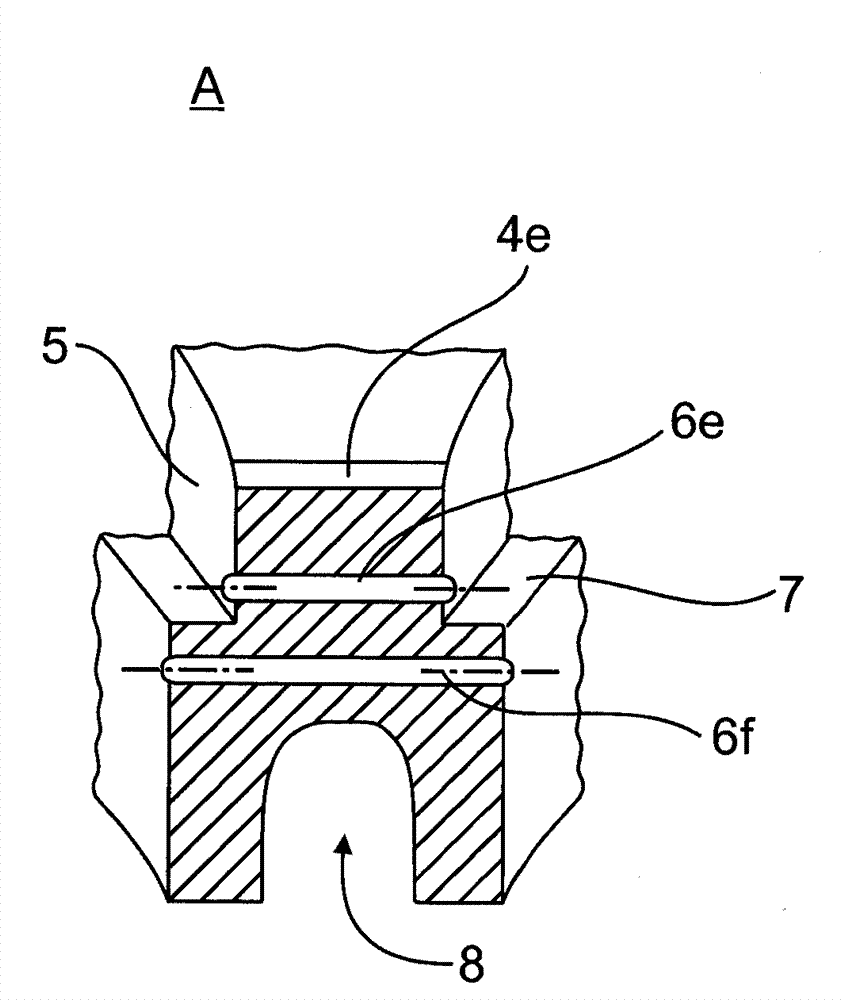

[0043] figure 2 A second alternative arrangement of the combination of crack initiation and crack arrestors is shown:

[0044] to this end, figure 2 A perspective plan view of a partial region of a four-valve cylinder head 1 with four valve seats 3 a , 3 b , 3 c , 3 d is shown. Here, compared to figure 1 The notches 4 a , 4 b , 4 c , 4 d are respectively arranged as crack initiations in the valve bridging region with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com