Superconductive heat pipe electric heater

A technology of electric heaters and superconducting tubes, applied in heating methods, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of slow temperature increase, poor heat dissipation effect, long heating time, etc., to achieve temperature balance, The effect of saving heating time and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

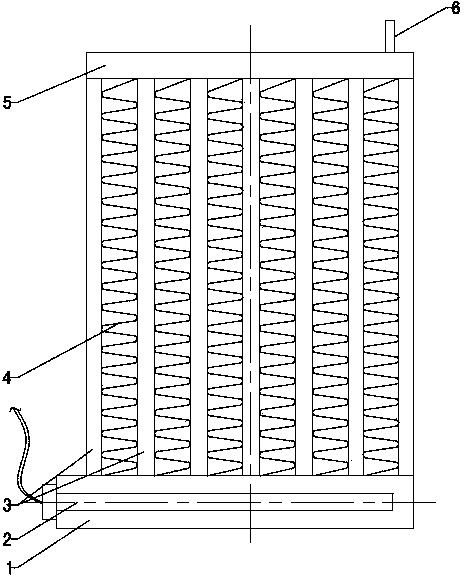

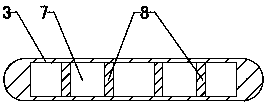

[0026] Refer to attached figure 1 , 2 And 4: The superconducting heat pipe electric heater includes a heater shell 9, an electric heating rod 2 and a heat dissipation fin 4, the heat conduction medium absorbs the heat released by the heating element and dissipates heat to the air through the heat dissipation fin 4, and the heater shell The circulation chamber 5 is installed on the upper part of the body 9, and the heating chamber 1 is installed on the bottom. The circulation chamber 5 and the heating chamber 1 are connected through a plurality of side-by-side heat pipes 3 as heat conduction elements. A circulation channel, the circulation chamber 5, the heating chamber 1 and the heat pipe 3 form a closed vacuum space, the circulation chamber 5, the heating chamber 1 and the heat pipe 3 are filled with heat conduction medium, and the electric heating rod 2 is installed in the heating chamber 1; the heat pipe 3 The inner wall of the heater housing 9 at the rear can also be equi...

Embodiment 2

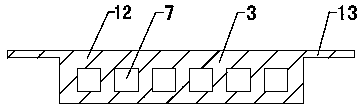

[0033] Refer to attached image 3: the heat pipe 3 is a flat tube with a T-shaped cross section, including a flat tube body 12, a medium circulation channel 7 and cooling fins 13, the flat tube body 12 is provided with a plurality of long strip through holes as the medium circulation channel 7, and the flat tube Radiating fins 13 are arranged symmetrically on both sides of the body 12 . The surface area of the upper and lower sides of the flat tube body 12 is relatively large, and the surface area of the left and right sides is relatively small. The cooling fins 13 are installed symmetrically on the left and right sides. The same plane as an extension of the upper or lower side. The vacuum degree in circulation chamber 5, heating chamber 1 and heat pipe 3 is 10 -3 Pa. When the heat pipe 3 dissipates heat outward, the heat dissipation fins 13 serve as auxiliary heat dissipation parts, effectively increasing the heat dissipation area of the heat pipe 3 and improving the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com