Gel heating pad and method for manufacturing same

A gel and heating layer technology, applied in the direction of electric heating devices, ohmic resistance heating, heating element materials, etc., can solve problems such as roughness, non-skin-friendly, hard touch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

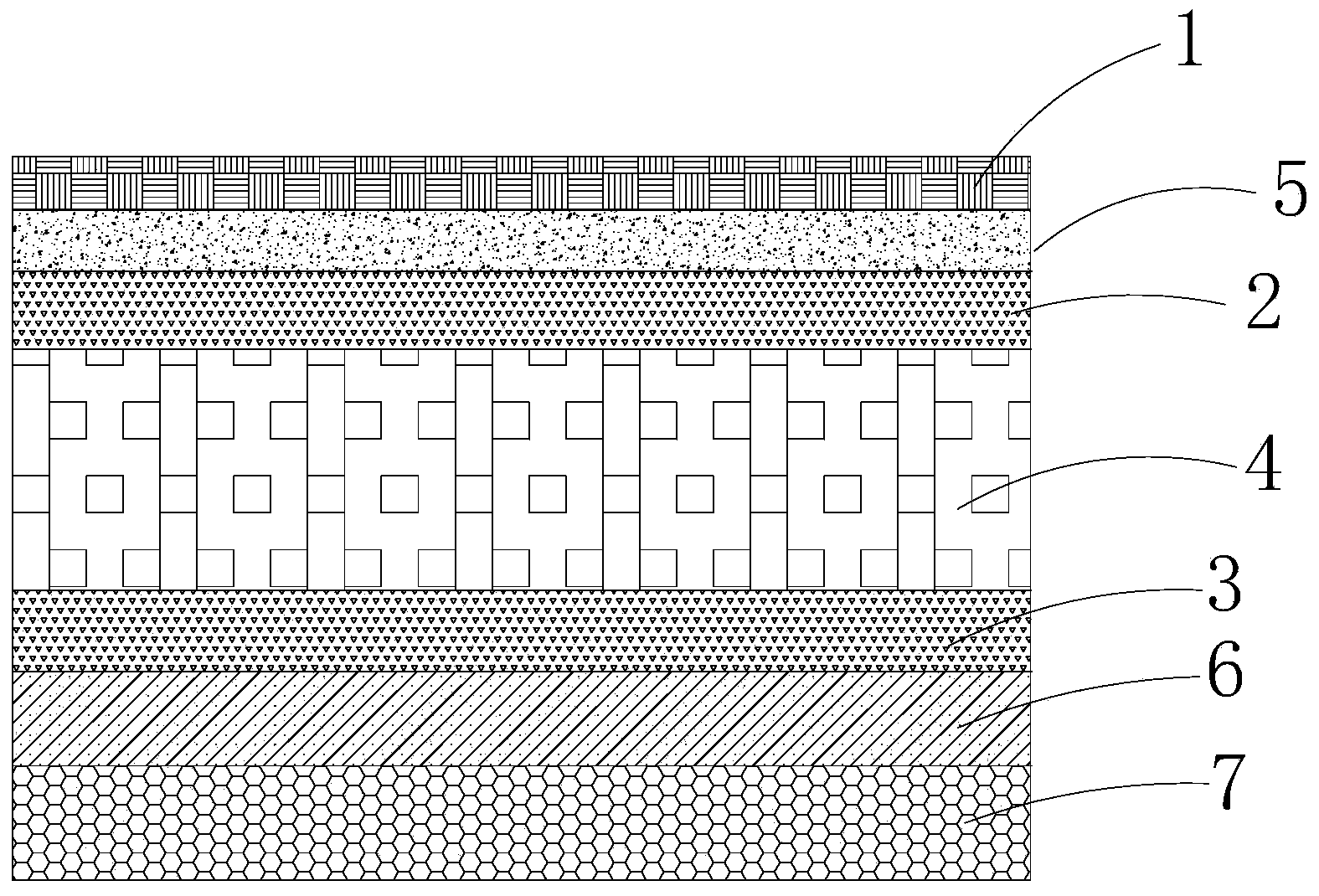

[0033] The technical characteristics of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0034] In the embodiment of the present invention, polyurethane materials A and B are produced by Shenzhen Youneng Rubber and Plastic Products Co., Ltd., and the product number is 3909500000; among them, 8301A: colorless transparent liquid, 500 ± 100 cps; 8301b: colorless transparent liquid, 800 ± 200cps.

[0035] The preparation method of the embodiment of the present invention is as follows:

[0036] 1) Put the HC-8301A / B raw materials into the A / B tank of the pouring machine respectively, and control the temperature at 20-50°C.

[0037] 2) If necessary, vacuum degas the raw materials of tank A / B first, and then adjust the proportion of tank A and B within the required range.

[0038] 3) Fine-tune the sample sheet, adjust the ratio and curing speed, etc.

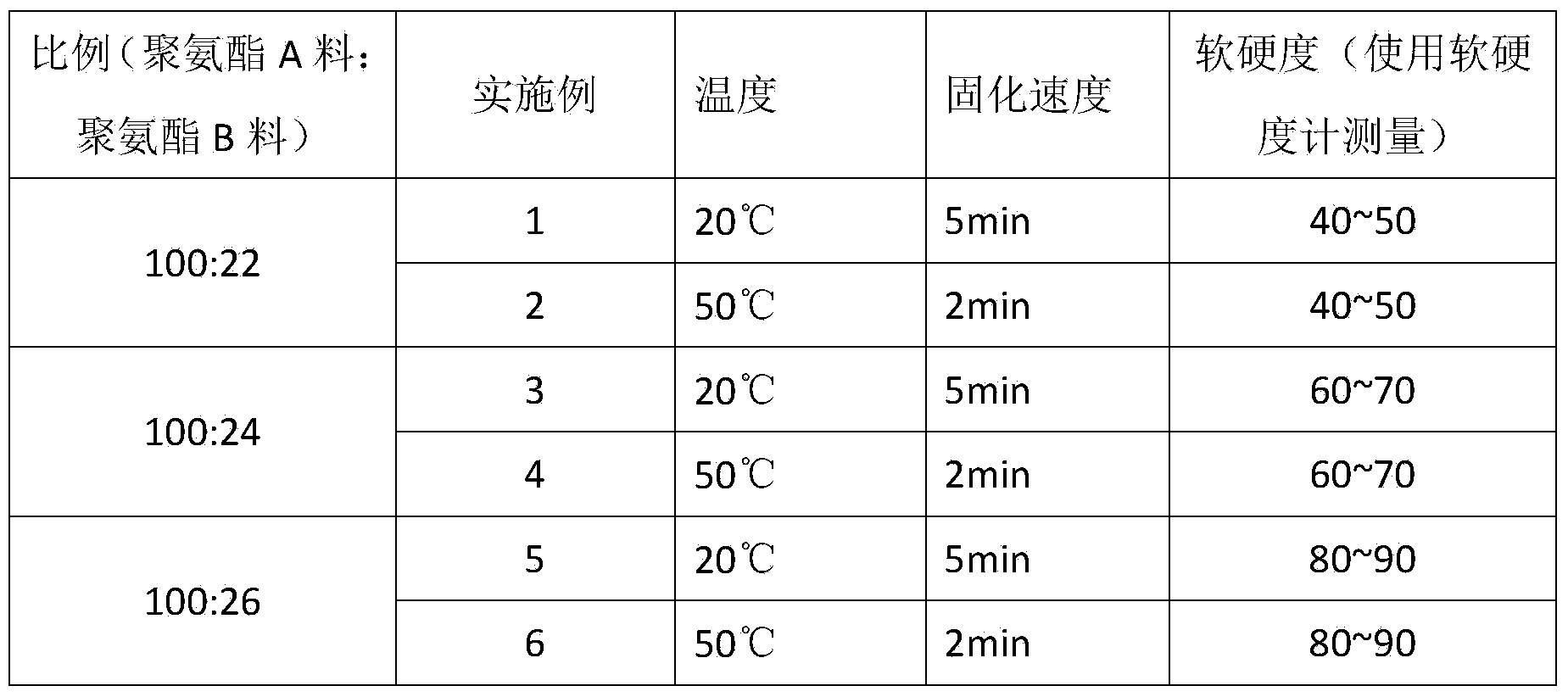

[0039] The addition ratio of the polyurethane A mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com