Heat conduction material-doped vanadium phosphorus oxide catalyst, preparation thereof and application thereof to selective catalytic oxidization synthesis of maleic anhydride with n-butane

A technology of heat-conducting materials and catalysts, applied in physical/chemical process catalysts, chemical instruments and methods, organic chemistry, etc., can solve the problems of uneven heating of catalysts, poor catalytic stability and selectivity, etc., to achieve mass production , improve catalytic activity, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

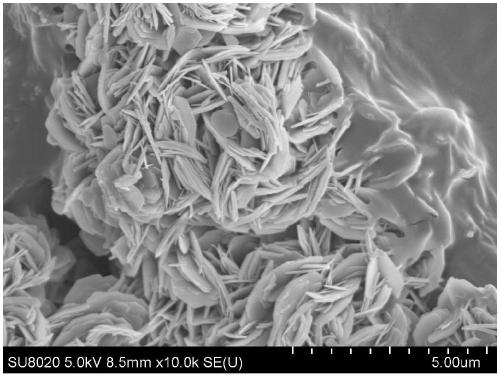

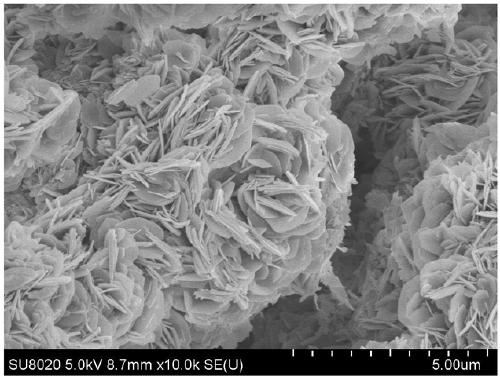

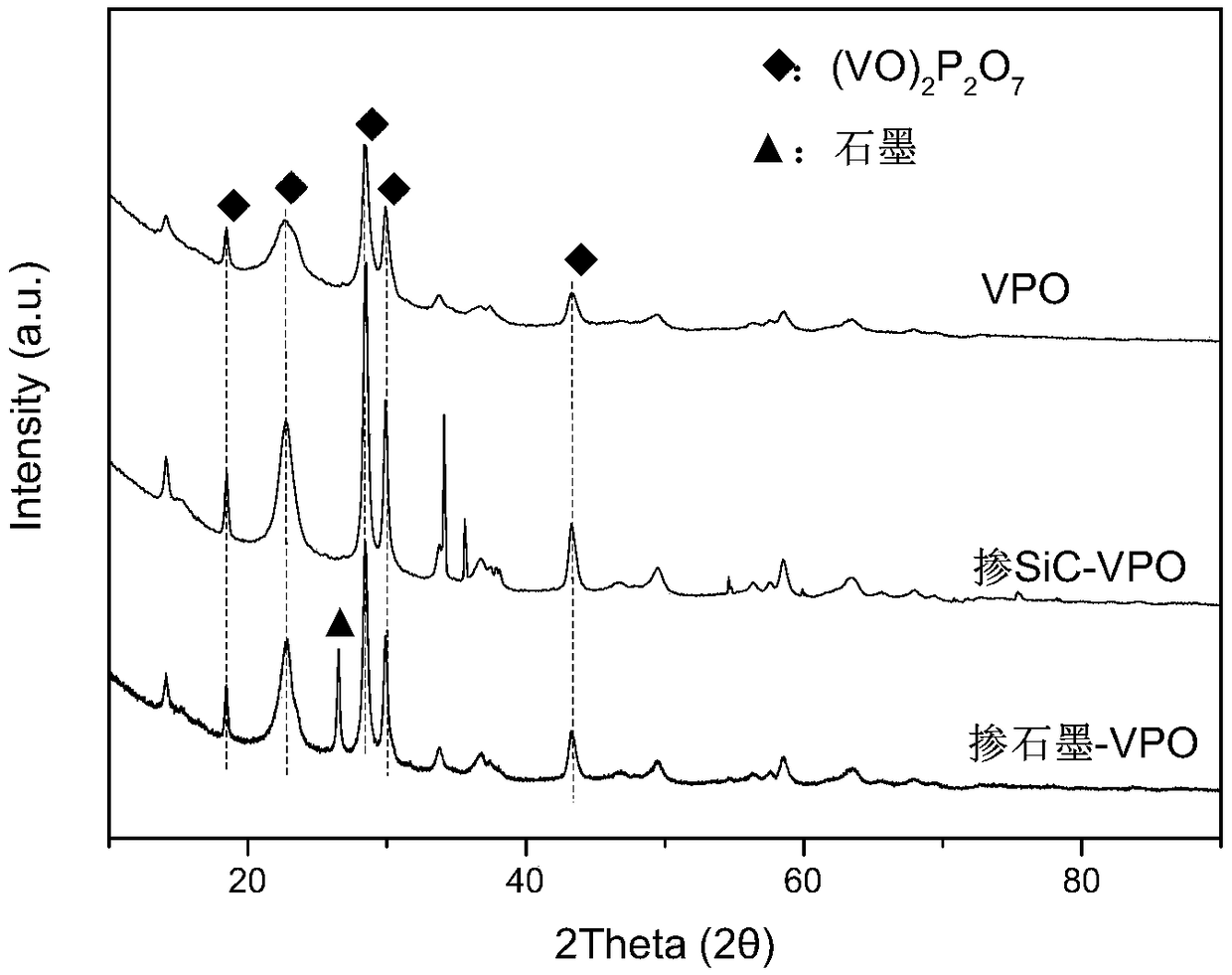

[0031] Weigh V 2 o 5 Put 20g in a 500ml flask, add a mixture of 200ml of isobutanol and 50ml of benzyl alcohol, then add 4.4g of SiC, stir and mix evenly, reflux at 136°C for 3 hours, then cool down to below 90°C, and then add dropwise at a constant speed H with a mass fraction of 85% 3 PO 4 15.5ml and stirred, then the temperature was raised to 136°C and reflux continued for 16 hours. Cool to room temperature, filter again, wash with ethanol and suction filter to obtain a sky blue precipitate. Collect and dry overnight in air at 120°C to obtain a catalyst precursor. Then, the obtained catalyst precursor powder was pressed into tablets under a pressure of 20 MPa, crushed, and 20-40 mesh catalyst particles were sieved. Afterwards, the catalyst particles were placed in the reaction atmosphere (C 4 h 10 / O 2 / N 2 =1.4 / 19.5 / 79.1) from room temperature to 430°C at a rate of 2°C / min for in-situ activation for 12 hours to obtain an activated vanadium-phosphorus-oxygen cata...

Embodiment 2

[0034] Weigh V 2 o 5 Put 20g in a 500ml flask, add a mixture of 200ml of isobutanol and 50ml of benzyl alcohol, then add 2.2g of SiC, stir and mix evenly, reflux at 136°C for 3 hours, then cool down to below 90°C, then add dropwise at a constant speed H with a mass fraction of 85% 3 PO 4 15.5ml and stirred, then the temperature was raised to 136°C and reflux continued for 16 hours. Cool to room temperature, filter again, wash with ethanol and suction filter to obtain a sky blue precipitate. Collect and dry overnight in air at 120°C to obtain a catalyst precursor. Then, the obtained catalyst precursor powder was pressed into tablets under a pressure of 20 MPa, crushed, and 20-40 mesh catalyst particles were sieved. The catalyst particles were then placed in a reaction atmosphere (C4H 10 / O 2 / N 2 =1.4 / 19.5 / 79.1) from room temperature to 430°C at a rate of 2°C / min for in-situ activation for 12 hours to obtain an activated vanadium-phosphorus-oxygen catalyst. The main ...

Embodiment 3

[0037] Weigh V 2 o 5 Put 20g in a 500ml flask, add a mixture of 200ml of isobutanol and 50ml of benzyl alcohol, then add 1.1g of SiC, stir and mix evenly, reflux at 136°C for 3 hours, then cool down to below 90°C, and then add dropwise at a constant speed H with a mass fraction of 85% 3 PO 4 15.5ml and stirred, then the temperature was raised to 136°C and reflux continued for 16 hours. Cool to room temperature, filter again, wash with ethanol and suction filter to obtain a sky blue precipitate. Collect and dry overnight in air at 120°C to obtain a catalyst precursor. Then, the obtained catalyst precursor powder was pressed into tablets under a pressure of 20 MPa, crushed, and 20-40 mesh catalyst particles were sieved. The catalyst particles were then placed in a reaction atmosphere (C4H 10 / O 2 / N 2 =1.4 / 19.5 / 79.1) from room temperature to 430°C at a rate of 2°C / min for in-situ activation for 12 hours to obtain an activated vanadium-phosphorus-oxygen catalyst. The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com