LED chip heat dissipation structure

A technology of LED chip and heat dissipation structure, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as affecting the life of LED light sources, and achieve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

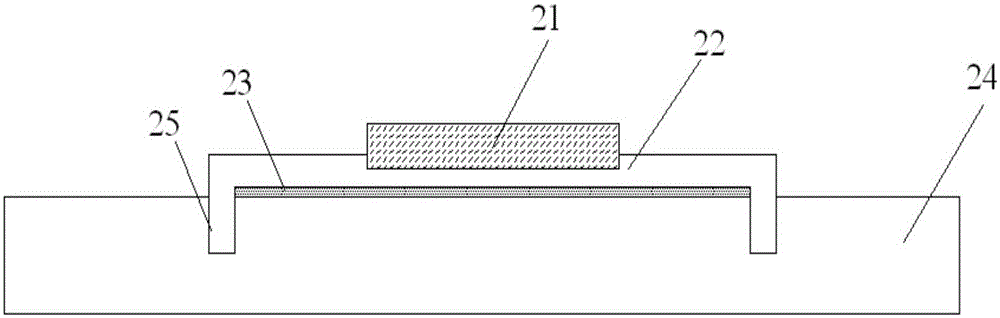

[0017] Such as figure 1 As shown, in the first embodiment of the present invention, a LED chip heat dissipation structure is provided, which includes an LED chip 21, a heat dissipation pad 22 and a heat dissipation substrate 24, a groove is provided on the heat dissipation pad, and the LED chip is arranged in the groove. Part of the side and bottom of the LED chip is in contact with the heat dissipation pad, wherein the heat dissipation pad is provided with at least one heat dissipation pin 25 , and a slot is provided on the heat dissipation substrate, and the heat dissipation pin is inserted into the slot. The form of the groove is not limited, and may be rectangular, square or circular.

[0018] The heat dissipation pad is metal, such as copper, silver or aluminum, and the heat dissipation substrate is a ceramic substrate, such as aluminum oxide or aluminum nitride.

[0019] In the present invention, the heat dissipation pad and the heat dissipation substrate can be combine...

no. 2 approach

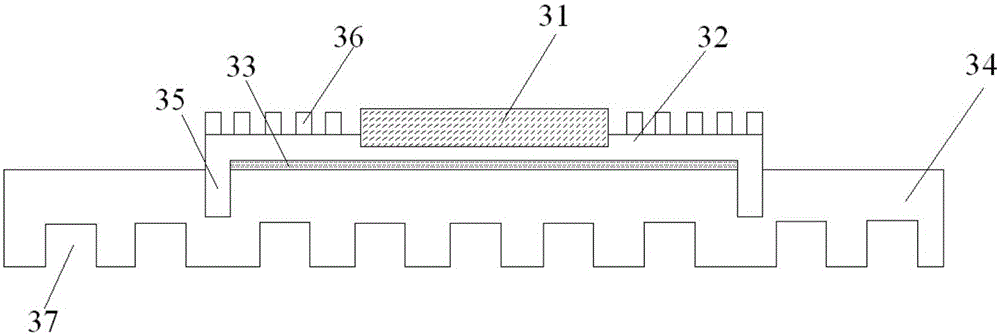

[0026] figure 2 The second embodiment of the present invention is illustrated, the LED chip heat dissipation structure, which includes the LED chip 31, the heat dissipation pad 32 and the heat dissipation substrate 34, the heat dissipation pad is provided with a groove, the LED chip 31 is arranged in the groove, and the LED chip 31 Part of the sides and the bottom are in contact with the heat dissipation pad 32 , wherein the heat dissipation pad is provided with at least one heat dissipation pin 35 , and a slot is provided on the heat dissipation substrate, and the heat dissipation pin 35 is inserted into the slot. The form of the groove is not limited, and may be rectangular, square or circular.

[0027] The heat dissipation pad is metal, such as copper, silver or aluminum, and the heat dissipation substrate is a ceramic substrate, such as aluminum oxide or aluminum nitride.

[0028] In this implementation, a ventilation groove 37 is provided below the heat dissipation subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com