Preparation method of copper foil electricity-conducting, heat-conducting, anti-shock and shielding adhesive tape

A technology of electrical conduction, heat conduction, and copper foil, which is applied in the direction of conductive adhesives, chemical instruments and methods, adhesives, etc., can solve the problem of lack of electrical conduction, heat conduction, shock resistance, shielding functions, unsatisfactory use of conductive tape, and affect the performance of electronic products And other problems, to achieve good conductive effect, simple structure, good viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

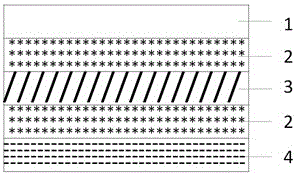

[0019] refer to figure 1 , the present embodiment proposes a method for preparing a copper foil conductive, thermally conductive, shock-resistant, and shielding adhesive tape, comprising the following steps:

[0020] S1: the substrate layer 3 is made of copper foil;

[0021] S2: Mix 20 parts by weight of nano-scale metal powder and 10 parts by weight of nano-scale graphite powder, then add 40 parts by weight of toluene, stir for 5 minutes, add 10wt% conductive heat transfer fluid, and stir for 15 minutes to obtain Conductive heat conduction glue;

[0022] S3: Use a release material to prepare the release material layer 1, use a coating machine to coat the conductive heat-conducting adhesive on the release material layer 1, and then cure it in an oven at 80°C for 5 minutes, and the conductive heat-conducting adhesive is cured into a conductive heat-conducting adhesive Layer 2, and then transferred to both sides of the base material layer 3, making a copper foil double-sided a...

Embodiment 2

[0025] refer to figure 1 , the present embodiment proposes a method for preparing a copper foil conductive, thermally conductive, shock-resistant, and shielding adhesive tape, comprising the following steps:

[0026] S1: the substrate layer 3 is made of copper foil;

[0027] S2: Mix 25 parts by weight of nanoscale metal powder and 13 parts by weight of nanoscale graphite powder, then add 50 parts by weight of toluene, stir for 8 minutes, add 13wt% conductive heat transfer fluid, and stir for 18 minutes to obtain Conductive heat conduction glue;

[0028] S3: Use a release material to prepare the release material layer 1, use a coating machine to coat the conductive and heat-conducting adhesive on the release material layer 1, and then cure it in an oven at 90°C for 8 minutes, and the conductive and heat-conducting adhesive will be cured into a conductive and heat-conducting adhesive Layer 2, and then transferred to both sides of the base material layer 3, making a copper foil...

Embodiment 3

[0031] refer to figure 1 , the present embodiment proposes a method for preparing a copper foil conductive, thermally conductive, shock-resistant, and shielding adhesive tape, comprising the following steps:

[0032] S1: the substrate layer 3 is made of copper foil;

[0033] S2: Mix 30 parts by weight of nano-scale metal powder and 15 parts by weight of nano-scale graphite powder, then add 60 parts by weight of toluene, stir for 10 minutes, add 15wt% conductive heat transfer fluid, and stir for 20 minutes to obtain Conductive heat conduction glue;

[0034] S3: Use a release material to prepare the release material layer 1, use a coating machine to coat the conductive and heat-conducting adhesive on the release material layer 1, and then cure it in an oven at 100°C for 10 minutes, and the conductive and heat-conducting adhesive is cured into a conductive and heat-conducting adhesive Layer 2, and then transferred to both sides of the base material layer 3, making a copper foil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com