Positioning tool clamp for precision box-shaped sensor welding and using method of positioning tool clamp for precision box-shaped sensor welding

A positioning tooling and sensor technology, applied in the field of welding tooling fixtures, can solve problems such as inaccurate positioning, relative slippage of components, poor installation visibility, etc., and achieve the effects of avoiding damage, preventing relative slippage, and facilitating observation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

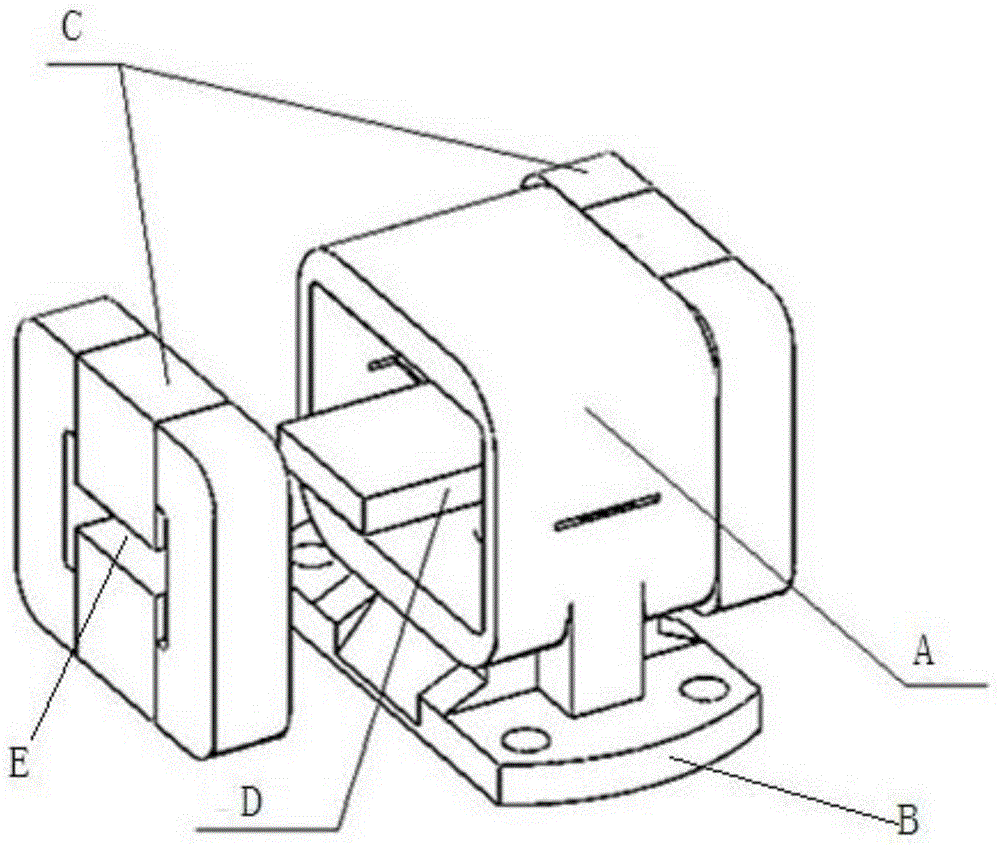

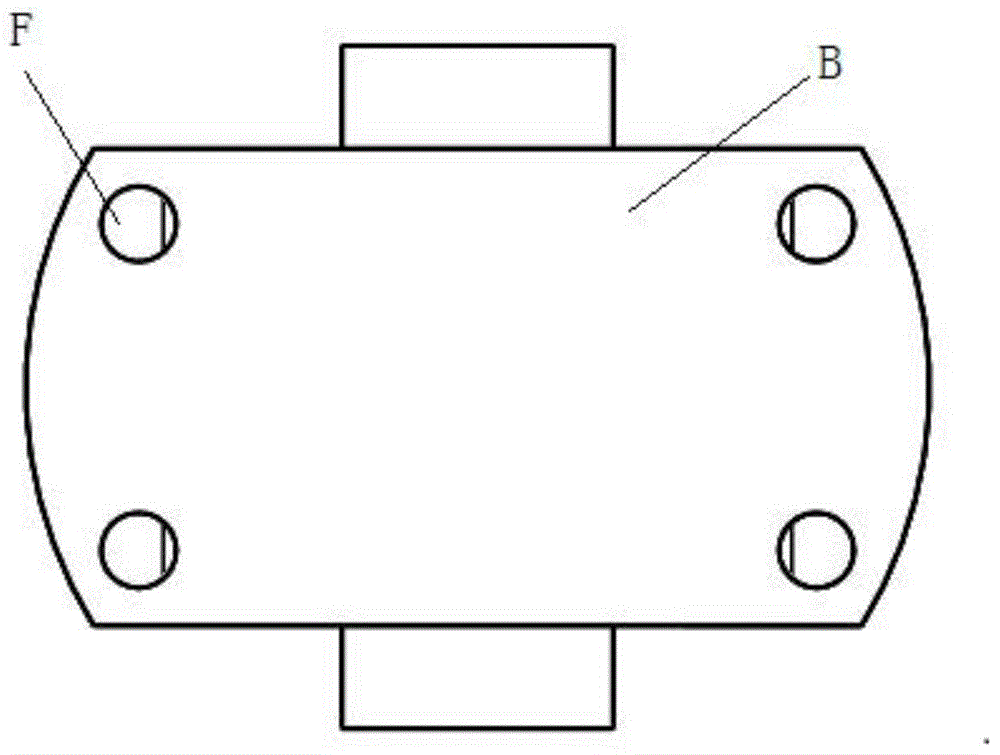

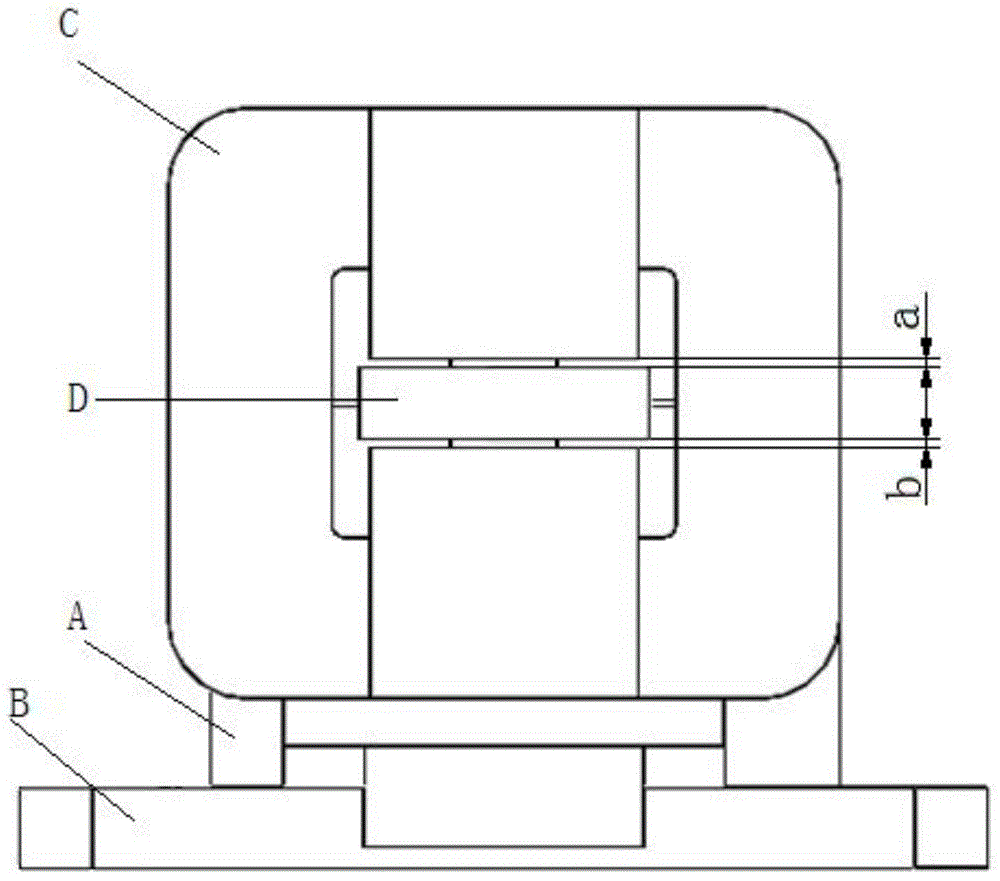

[0028] as attached figure 1 As shown in -3, the existing box-type sensor is composed of a body A, a base B, a cover plate assembly C and an extension plate D, and the extension plate D extends into the middle hole E of the cover plate assembly C, and is connected with the The gap width of the upper and lower edges is the same, and the error is not more than ±0.02mm. This requires that in the spot welding connection between the cover assembly C and the body A, the relevant components of the box-type sensor should be adjusted and fixed in advance according to the error requirements.

[0029] as attached Figure 4 As shown in -5, the positioning fixture of this patent includes an upper plate 1, a middle plate 2, a lower plate 3, a guide rail sleeve 4, a column 5, a heat dissipati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com