Ceramic fiber blowing cotton packing device and method

A technology of ceramic fiber and blown cotton, applied in the direction of packaging, transportation and packaging, single objects, etc., can solve the problems of uncontrollable weight, time-consuming and labor-consuming, large volume, etc. Control precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

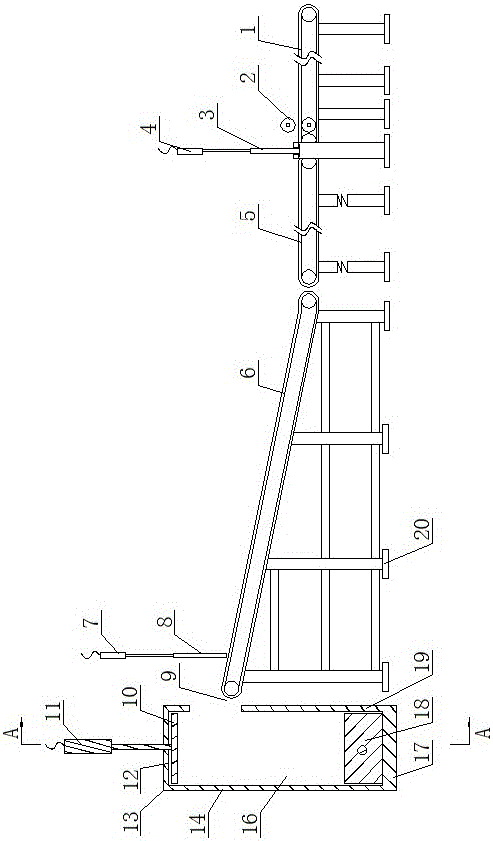

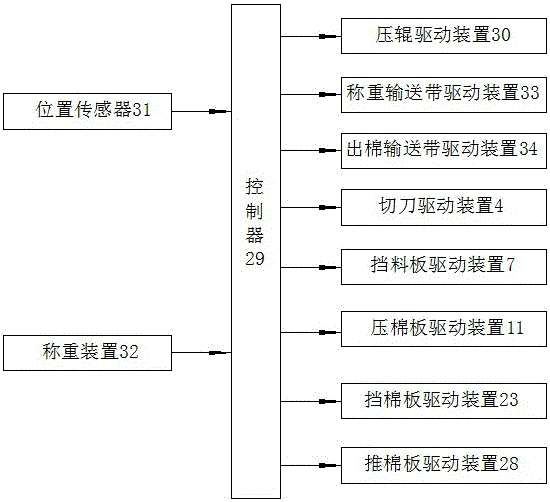

[0047] as attached figure 1 , attached figure 2 And attached image 3 As shown, the ceramic fiber blown cotton packaging device of the present invention includes a controller 29, a bagging device, a conveyor belt frame 20, and a conveyor belt and a conveyor belt driving device assembled on the conveyor belt frame 20, and the conveyor belt includes sequentially arranged The cotton feeding conveyor belt 1, the weighing conveyor belt 5 and the cotton discharging conveyor belt 6, the conveyor belt rack 20 below the weighing conveyor belt 5 corresponds to a weighing device 32; the cotton feeding conveyor belt 1 and the weighing conveyor belt 5 A cutter 3 is provided, and a cutter driving device 4 is connected to the cutter 3, and the cutter driving device 4 drives the cutter 3 to cut ceramic fiber blown cotton to obtain ceramic fiber blown cotton blocks of predetermined weight; bagging The device includes a box body 13, a cotton pressing device and a cotton pushing device. The b...

Embodiment 2

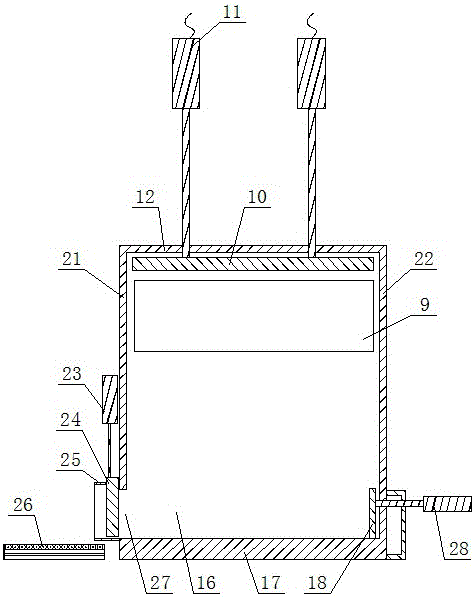

[0061] as attached Figure 4 , attached Figure 5 And attached Figure 6 As shown, the ceramic fiber blown cotton packaging device of the present invention is a further improvement on the basis of Embodiment 1. The difference between this embodiment and Embodiment 1 is: the box body 13 is a cuboid box body, including a bottom wall 17, a top The wall 12, the side wall I19 and the side wall III14 which are arranged opposite to each other on the left and right, and the side wall II21 and the side wall IV22 which are arranged opposite to the front and back, the cotton inlet 9 is opened on the upper end of the side wall I19, and the cotton outlet 27 is opened on the side wall II21 and The lower end of any one of the side walls IV22; a partition 15 is arranged between the side wall I19 and the side wall III14 in the box body 13, the partition 15, the side wall II21, the side wall I19, the side wall IV22 and the bottom The wall 17 forms the forming chamber 16 with an open top surfa...

Embodiment 3

[0070] The packing method of ceramic fiber blown cotton is a method for packing ceramic fiber blown cotton by adopting the packing device of ceramic fiber blown cotton in embodiment 1. The input end of the cotton feeding conveyor belt 1 is communicated with the cotton collector, 25 upper sleeve cotton bags, including the following workflow:

[0071] (1) Import ceramic fiber blown cotton: the controller 29 cooperates with the conveyor belt driving device, and the ceramic fiber blown cotton is sequentially introduced into the cotton feeding conveyor belt 1 and the weighing conveyor belt 5;

[0072] (2) Obtain a predetermined weight of ceramic fiber blown cotton: the controller 29 cooperates with the weighing device 32 and the cutter driving device 4 respectively, and the ceramic fiber blown cotton is weighed by the weighing device 32, and is cut Knife 3 cuts the ceramic fiber blown cotton into ceramic fiber blown cotton blocks of predetermined weight;

[0073] (3) Quickly impor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com