Sealing element for a hydraulically-actuated friction clutch

A technology for friction clutches and sealing elements, which is applied to clutches, engine seals, fluid-driven clutches, etc., can solve the problems of troublesome and expensive manufacturing, complex structure of friction clutches, etc., and achieve the effect of simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

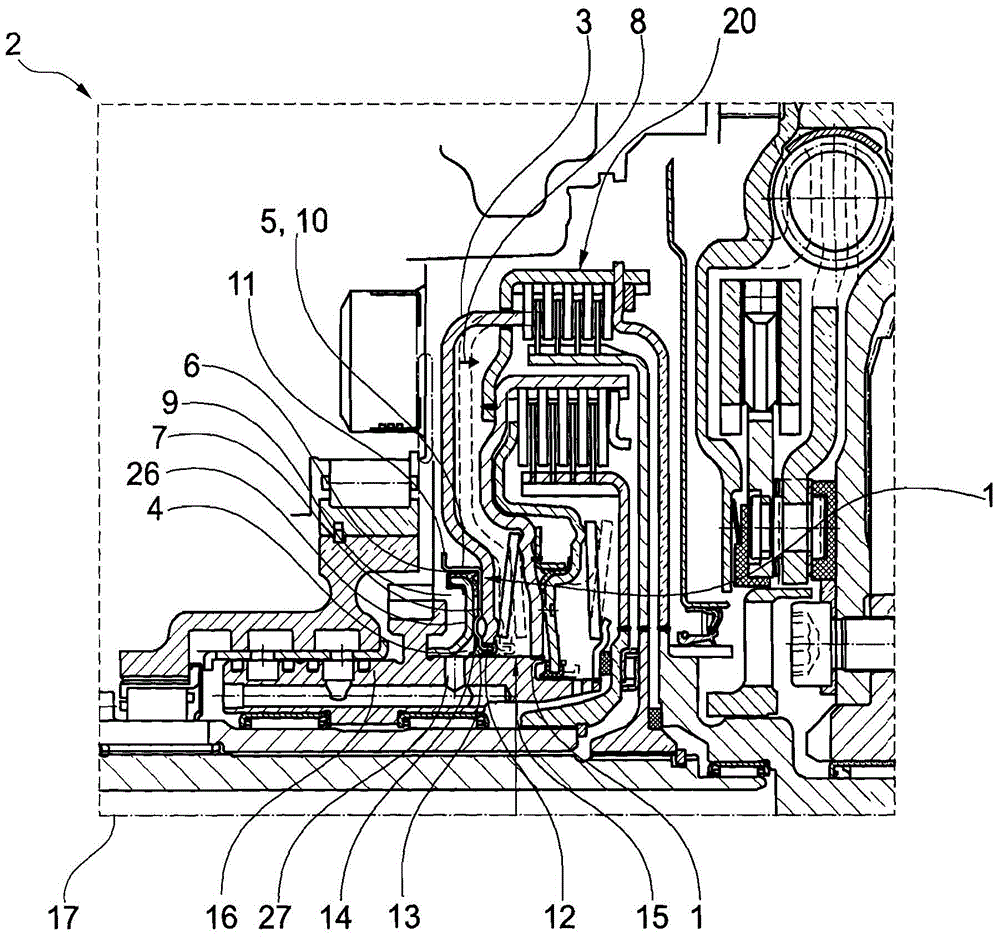

[0036] figure 1 A detail of a friction clutch 2 is shown, in which a separate sealing element 1 is arranged separately next to an actuating piston 3 , which is provided in the axial direction of movement for pressing against a disk pack 20 . In this case, the sealing element 1 is pot-shaped and surrounds the pressure chamber 4 on both sides with its pot wall 10 and its displacement surface 7 , which is simultaneously formed as a sliding surface 5 . The rear wall 26 of the pressure chamber 4 is arranged rigidly on the rotor 16 and thus delimits the pressure chamber 4 . In order to ensure a minimum distance between the actuating piston 3 or the sealing element 1 and the rear wall 26 , the sealing element 1 has an axial stop 14 which is integrated into the displacement surface 7 . Arranged on the rear wall 26 is a first axial sealing means 6 which slides on the sliding surface 5 . In order to stabilize the sliding surface 5 or the tank wall 10 , a flange 11 is provided which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com