Method for conveying vehicle body between welding production lines and welding device

A welding production line and car body technology, applied in the field of car body manufacturing, can solve problems such as difficulty in grasping the rhythm of car body transportation, affecting production efficiency, production delays, etc., and achieve the effects of saving machine transportation time, increasing production tempo, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

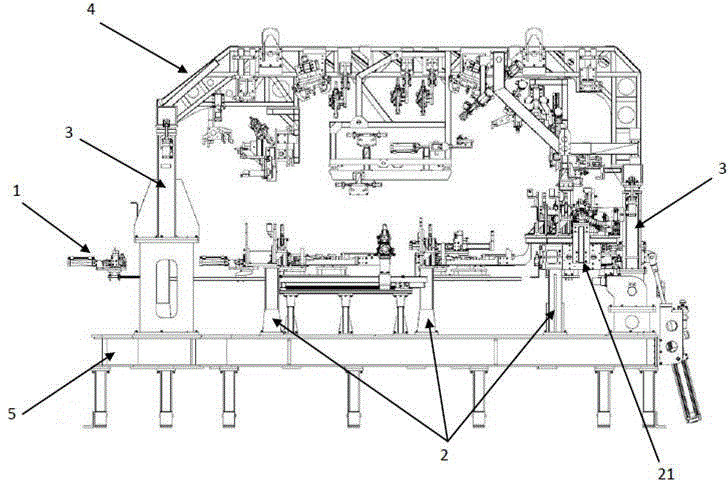

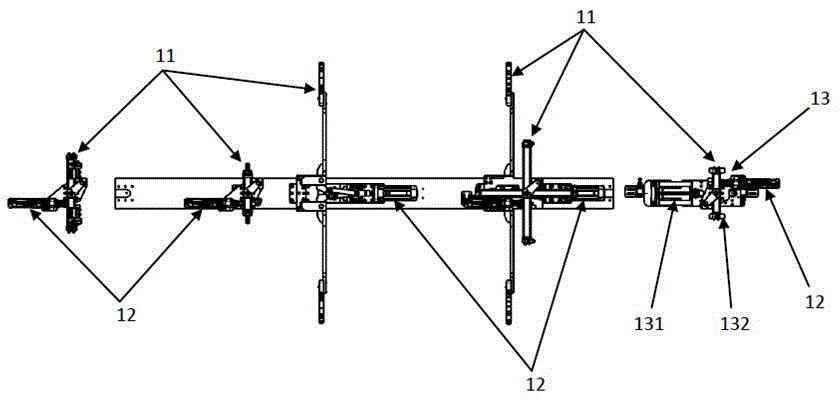

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

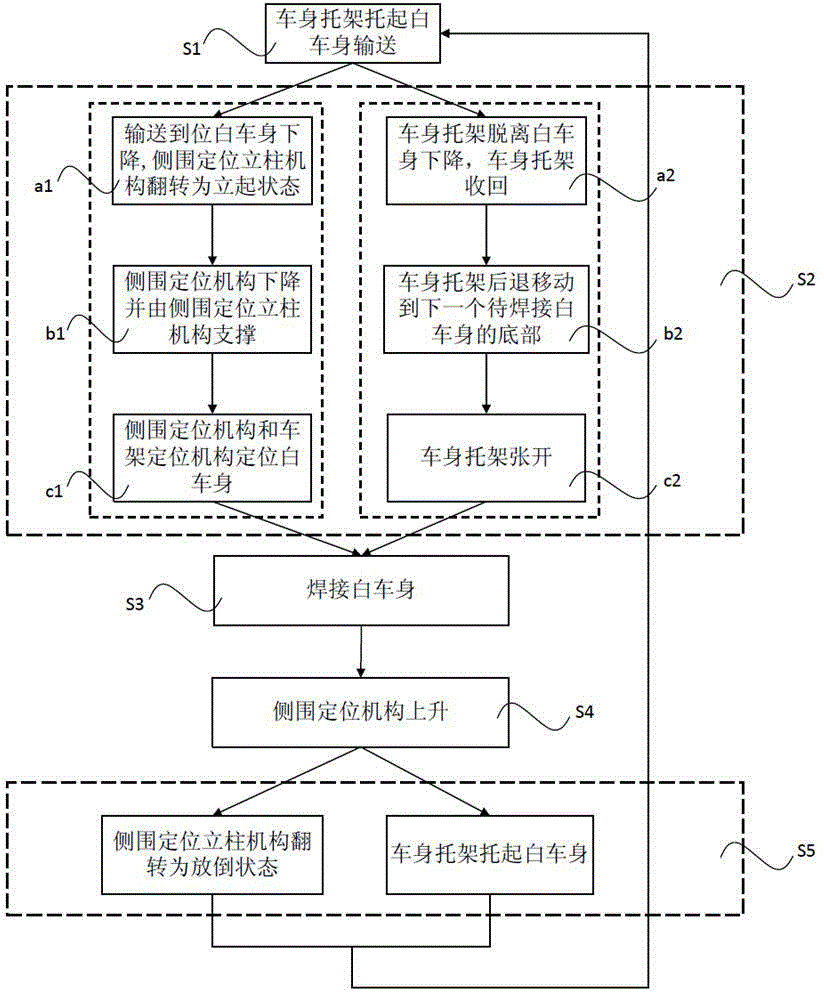

[0031] combine figure 1 As shown, the S1 body bracket supports the body-in-white for transportation: the body-in-white bracket 11 of the body conveying mechanism 1 is lifted upwards under the drive of the liftable lifting guide rail, supports the body-in-white and transports the body-in-white to the welding station.

[0032] S2 sends the body-in-white to the welding station and positions the body-in-white, including the following steps:

[0033] a1 conveyed in place, the body-in-white is lowered, and the side wall positioning column mechanism is turned over to the upright state; a2, the body bracket is detached from the body-in-white and lowered, and the body bracket is retracted: the side wall positioning column mechanism 3 includes a reversible rear positioning column 32, which is placed on the body-in-white During the conveying process, the rear posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com