High-solidified oil floating-roof oil tank space heating device

A technology of floating roof oil tanks and heating devices, which is applied in the field of pipeline systems and can solve problems such as high energy consumption and restrictions on the economic benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

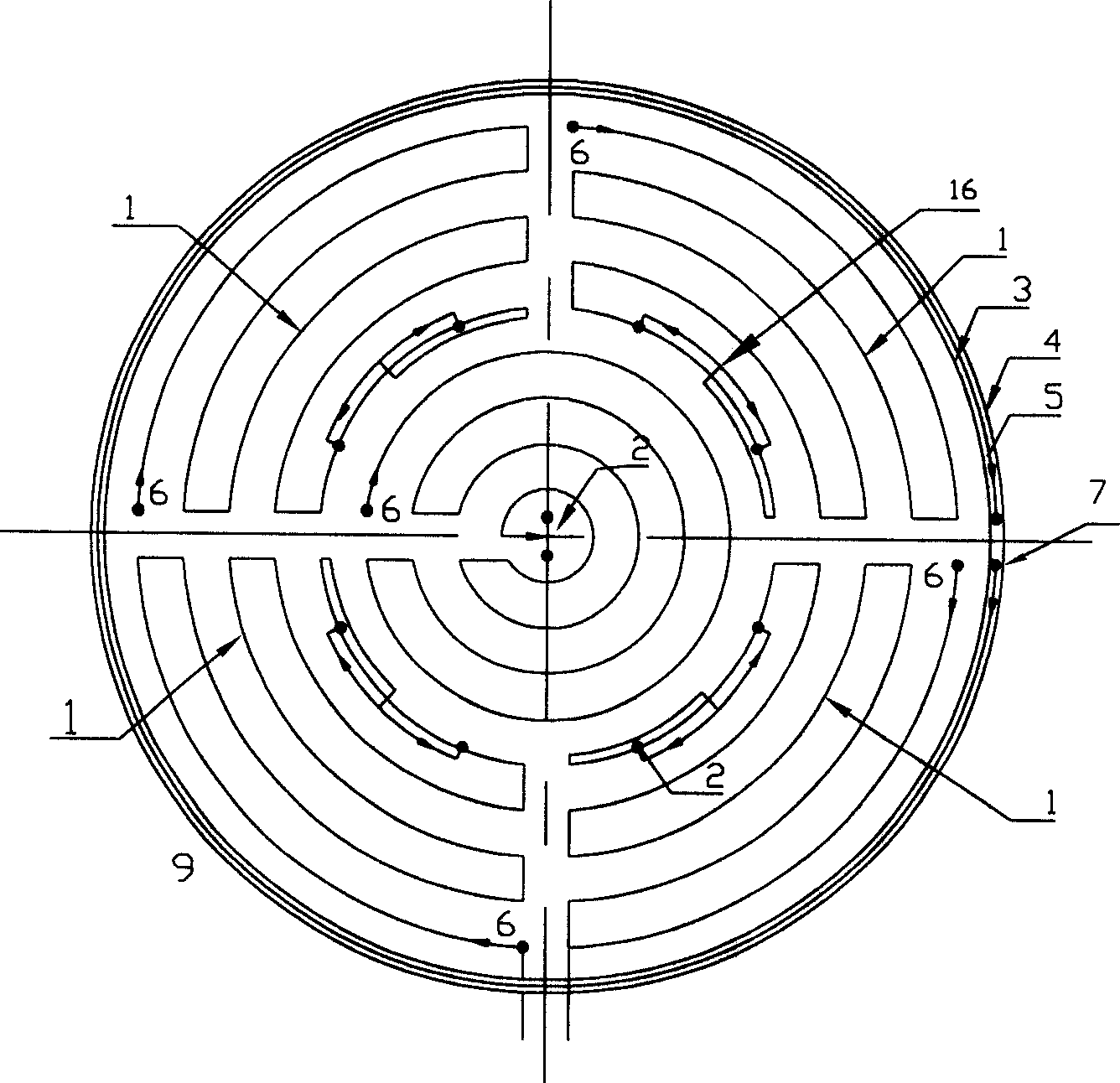

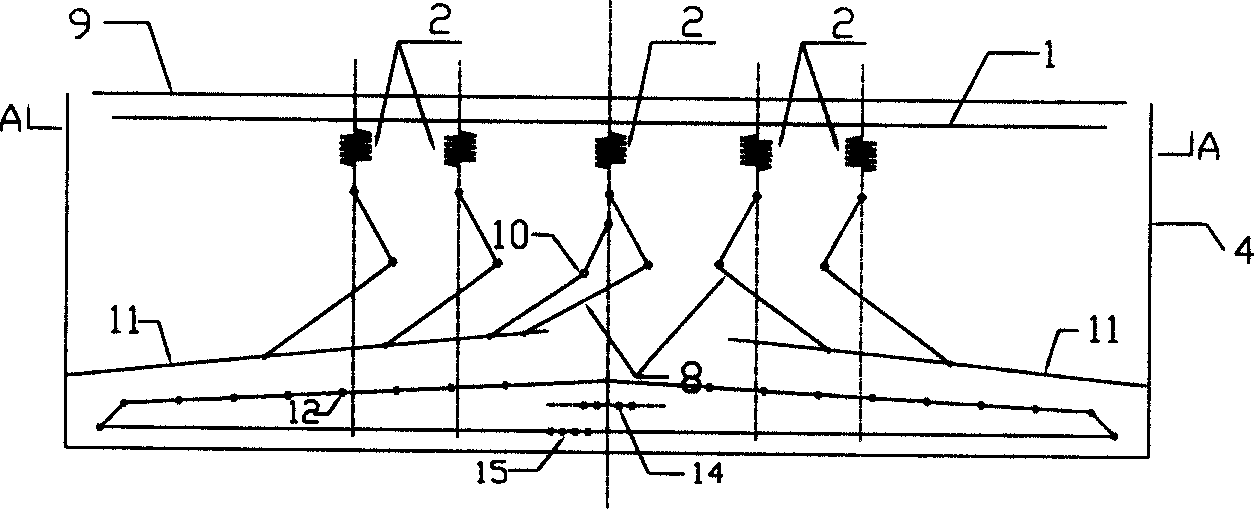

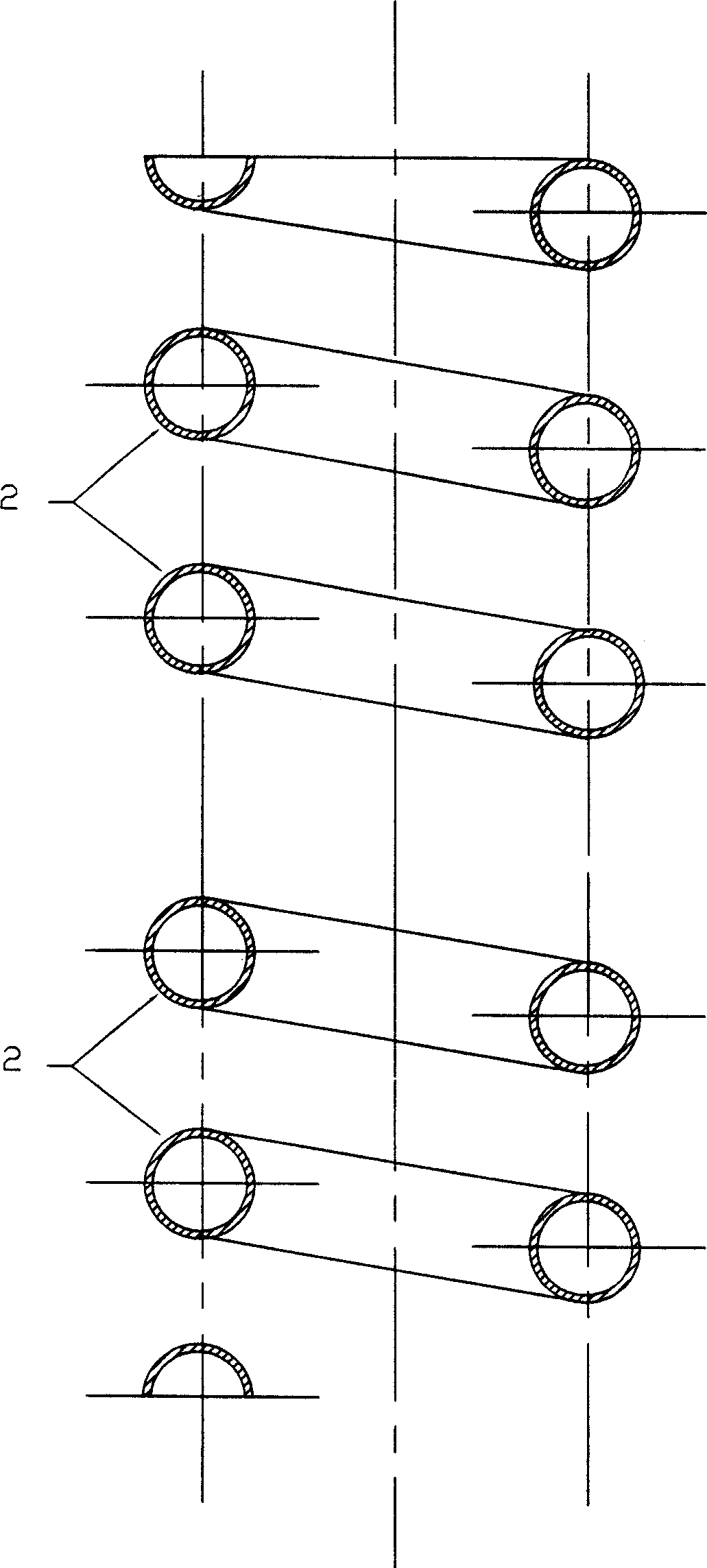

[0008] Example: Take 10 x 10 4 m 3 Take the storage of Daqing crude oil in a single-disk floating roof oil tank as an example. The wax content of Daqing crude oil is about 30%, and the freezing point is 32.5°C. In the northern part of our country, heating and storage is required in autumn, winter and spring. In this type of oil storage tank, the original tank bottom heater is used, and the tank top heater and the vertical spiral steam pipe 2 heater are added. The structure of the tank bottom heater is as follows: Figure 4 , Figure 5 Shown, it is formed by 12 coils of 4 steam pipes, and steam pipe 12 is the steel pipe of 114, and total length is 1417m, and steam supply pressure is 0.4Mpa (gauge pressure). The structure of the tank roof heater is as follows figure 1 , figure 2 As shown, five horizontal steam pipes 1 are respectively connected to serpentine coils in a central small circle area and four equal small sector areas around them. The steam pipe 1 is made of 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com