Garbage water separation equipment

A technology for separating equipment and moisture, which is applied in the field of garbage moisture separation equipment, and can solve the problems of inability to continue the operation of garbage moisture separation, difficulty in cleaning, and high moisture content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

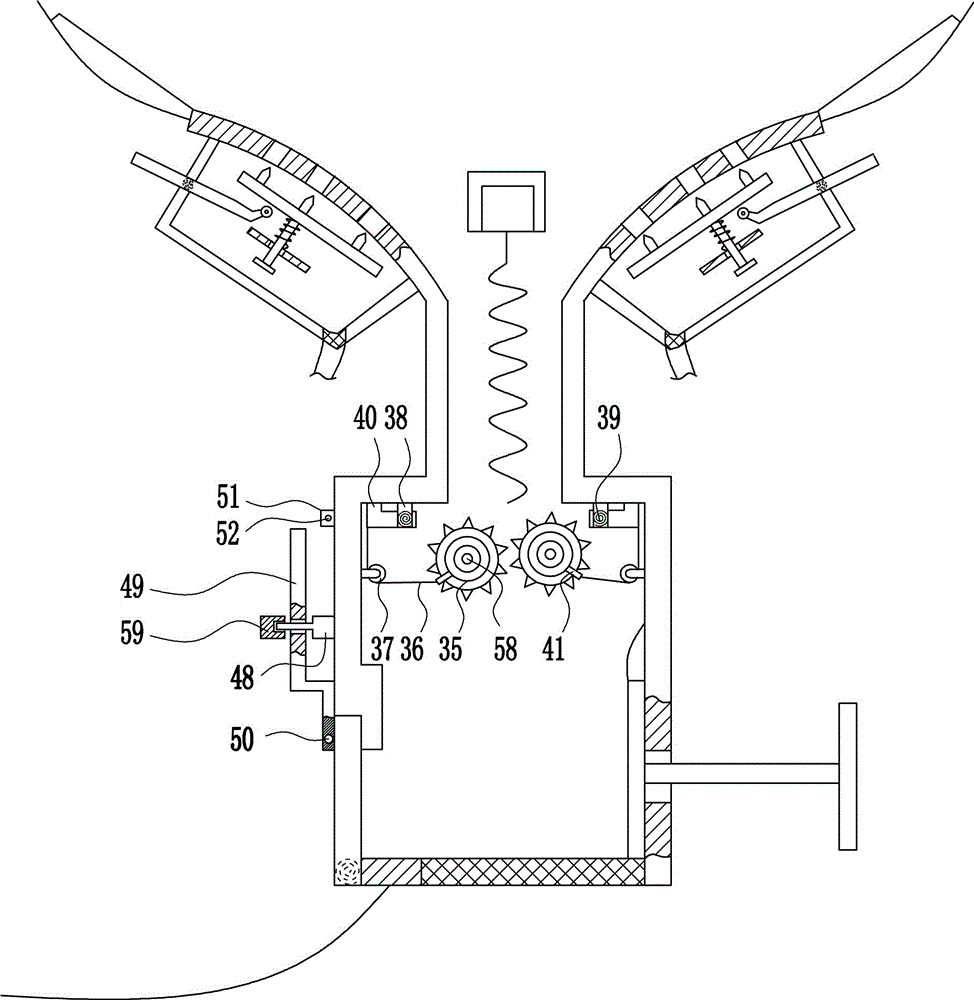

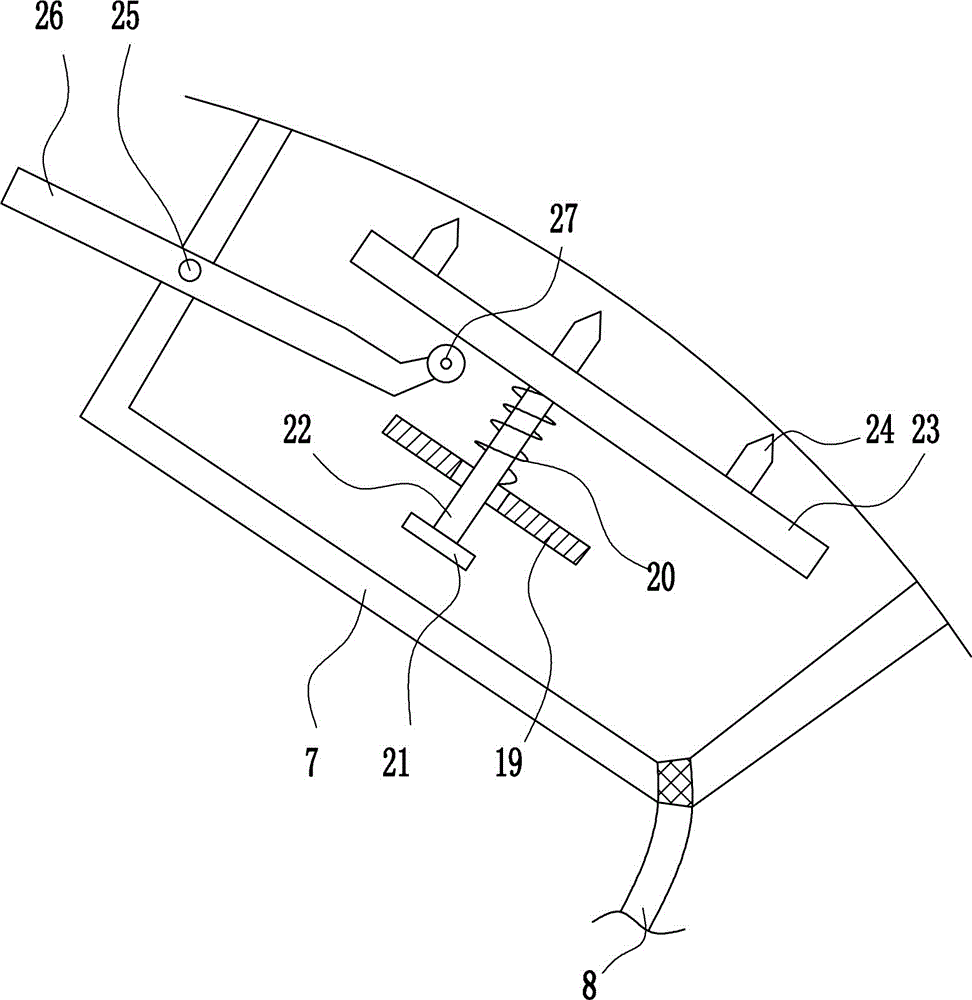

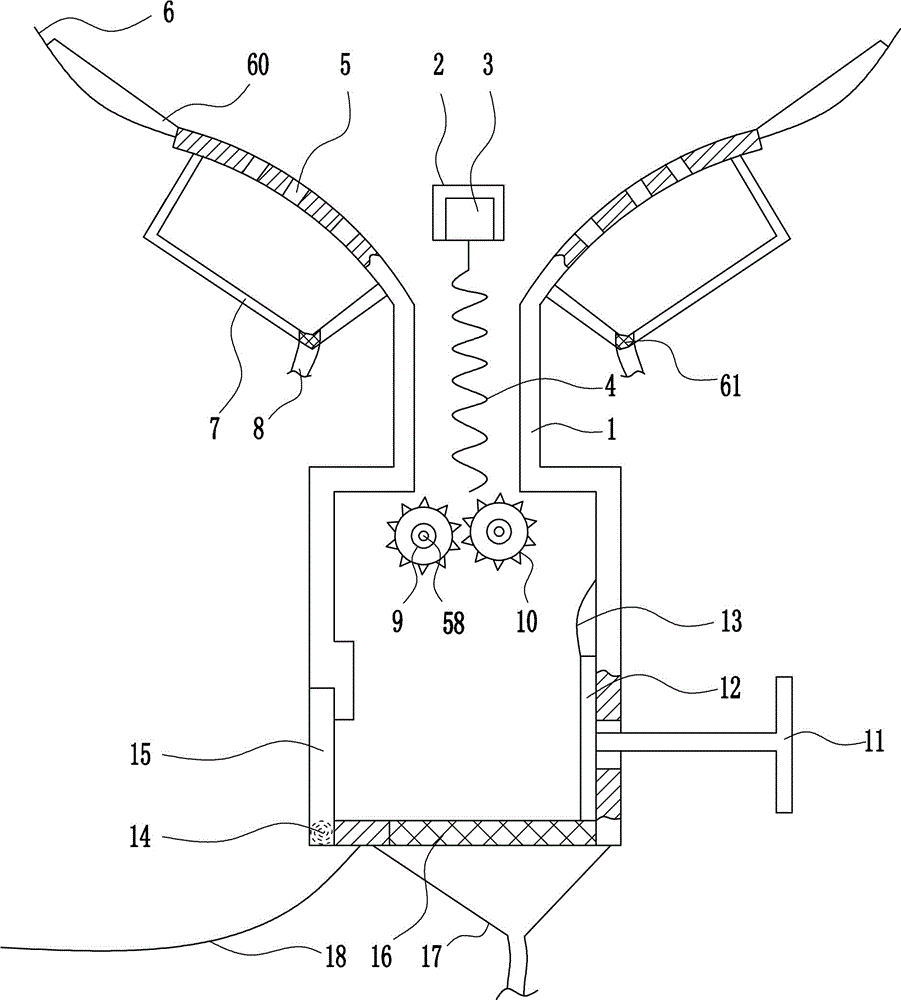

[0035] A kind of garbage water separation equipment, such as Figure 1-5 As shown, it includes a treatment box 1, a protective cover 2, a first motor 3, a screw rod 4, a first material guide plate 6, a collection box 7, a water outlet pipe 8, a second motor 9, a crushing drum 10, a push rod 11, Push plate 12, elastic film 13, the first torsion spring 14, the first baffle plate 15, the first filter screen 16, collecting bucket 17, the second material guide plate 18, the second rotating rod 58, the second baffle plate 60 and the first Two filter screens 61, the top of the processing box 1 is conical shape, the upper rear wall in the processing box 1 is connected with the protective cover 2 by means of screw connection, the protective cover 2 is provided with the first motor 3, the output shaft of the first motor 3 The top is connected with a screw rod 4 through a coupling, the first through hole 5 is evenly opened on the left and right sides of the upper part of the processing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com