Production process for single-direction rapid moisture guide composite knitted fabric

A technology of knitted fabrics and production technology, which is applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of long drying time and uncomfortable users, achieve improved temperature and heat balance, significant differential effect, and improve conductivity. The effect of wet performance and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

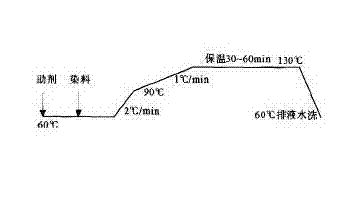

[0053] Example 1: The technological process of the unidirectional fast moisture-wicking composite knitted fabric.

[0054] 1. Weaving:

[0055] 1.1. Selection of raw materials.

[0056] According to the principle of moisture conduction in the present invention, the selection of raw materials is carried out. The inner layer of the fabric chooses hydrophobic fibers with better moisture conductivity, such as cooldry, coolplus, and coolmax fibers, and the outer layer of the fabric chooses hydrophilic fibers with better hygroscopicity, which are selected from natural fibers and regenerated fibers, such as cotton yarn, viscose, and natural fibers. The inner and outer layers are connected by hydrophobic and moisture-conducting fibers. The hydrophobic and moisture-conducting fibers are selected from honeycomb absorbing polyester, honeycomb absorbing polyester / tencel, and coolmax fibers, so that sweat can easily pass from the inner layer of the fabric to the outer layer and quickly e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com