Reflective type high-power light-emitting diode (LED) packaging structure

An LED packaging and high-power technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the brightness of LED lighting, reducing the utilization rate of LED lighting, and achieving the effects of simple structure, improved service life, and high thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

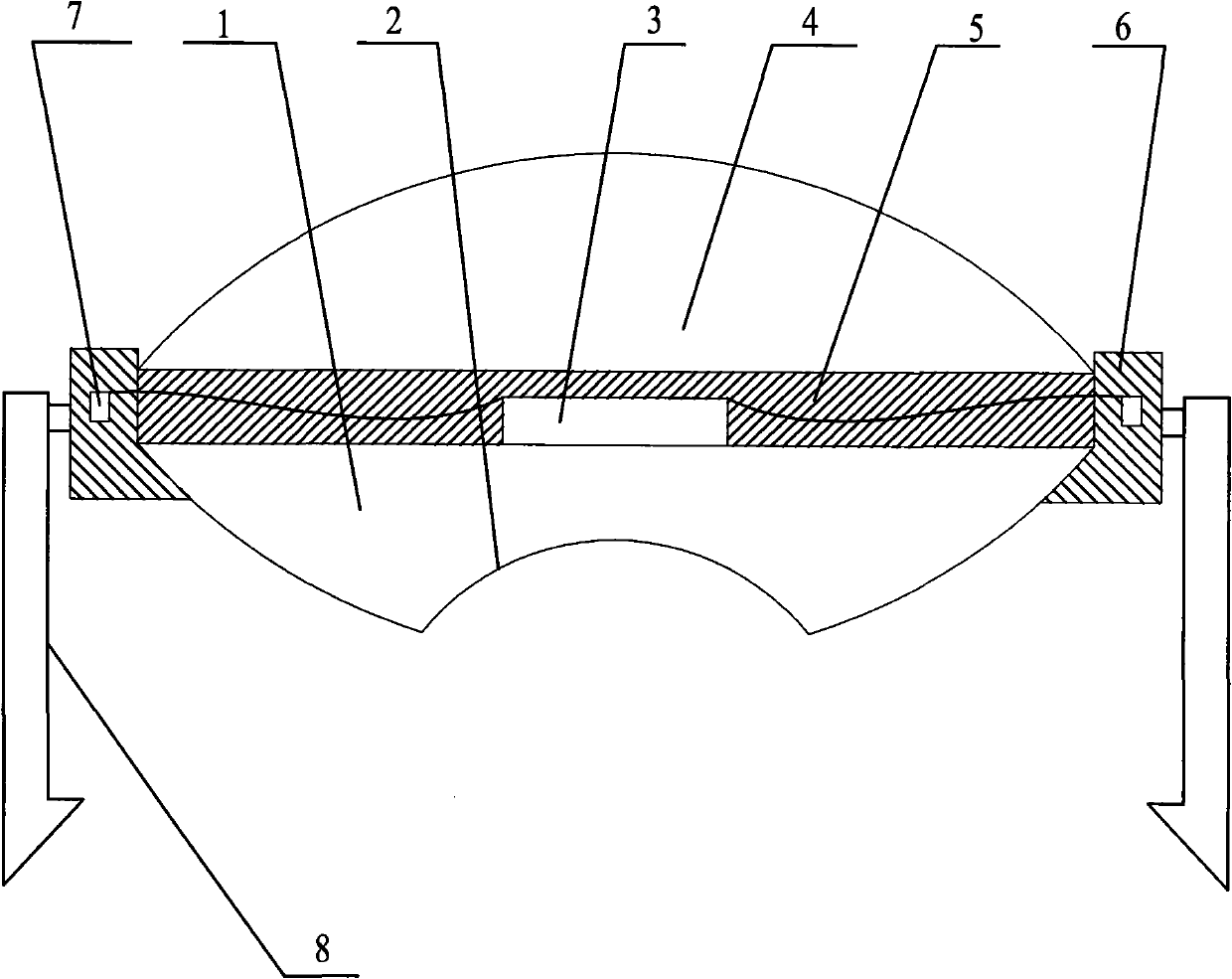

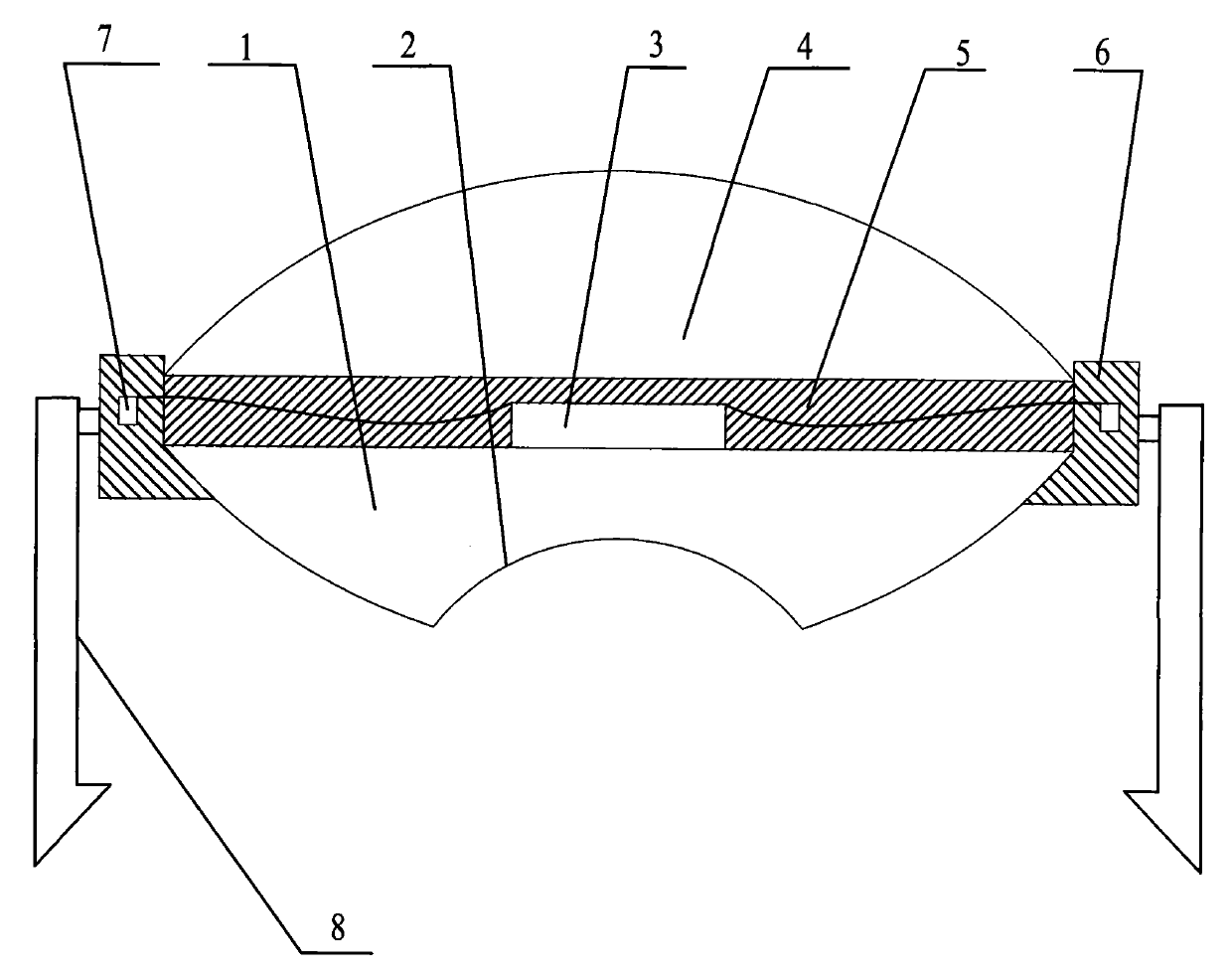

[0015] like figure 1 As shown: the present invention includes a reflective substrate 1 , a reflective groove 2 , an LED light-emitting chip 3 , a focusing lens 4 , silica gel 5 , a fixing bracket 6 , a conductive electrode 7 and a conductive pin 8 .

[0016] like figure 1 As shown: the LED light-emitting chip 3 is placed on the reflective substrate 1 , the outer peripheral surface of the reflective substrate 1 is surrounded by a fixed bracket 6 , and the fixed bracket 6 is fixedly connected with the reflective substrate 1 . The fixed support 6 is provided with a fixedly connected conductive electrode 7 , and the conductive electrode 7 is electrically connected to the LED light-emitting chip 3 by wires, and is used to provide power to the LED light-emitting chip 3 . The fixed bracket 6 is provided with a fixedly connected conductive pin 8, the conductive pin 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com