Method and equipment for producing yellow phosphorus by utilizing closed annular heating furnace

A ring-shaped heating furnace and yellow phosphorus technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of difficult exhaust gas purification technology of phosphorus furnace, low utilization rate of exhaust gas, poor applicability, etc., and achieve saving The effect of high-quality fuel, shortening the time of preheating zone, and improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The equipment for producing yellow phosphorus provided by the present invention and the method for producing yellow phosphorus using the equipment will be described in detail below in conjunction with the accompanying drawings and examples.

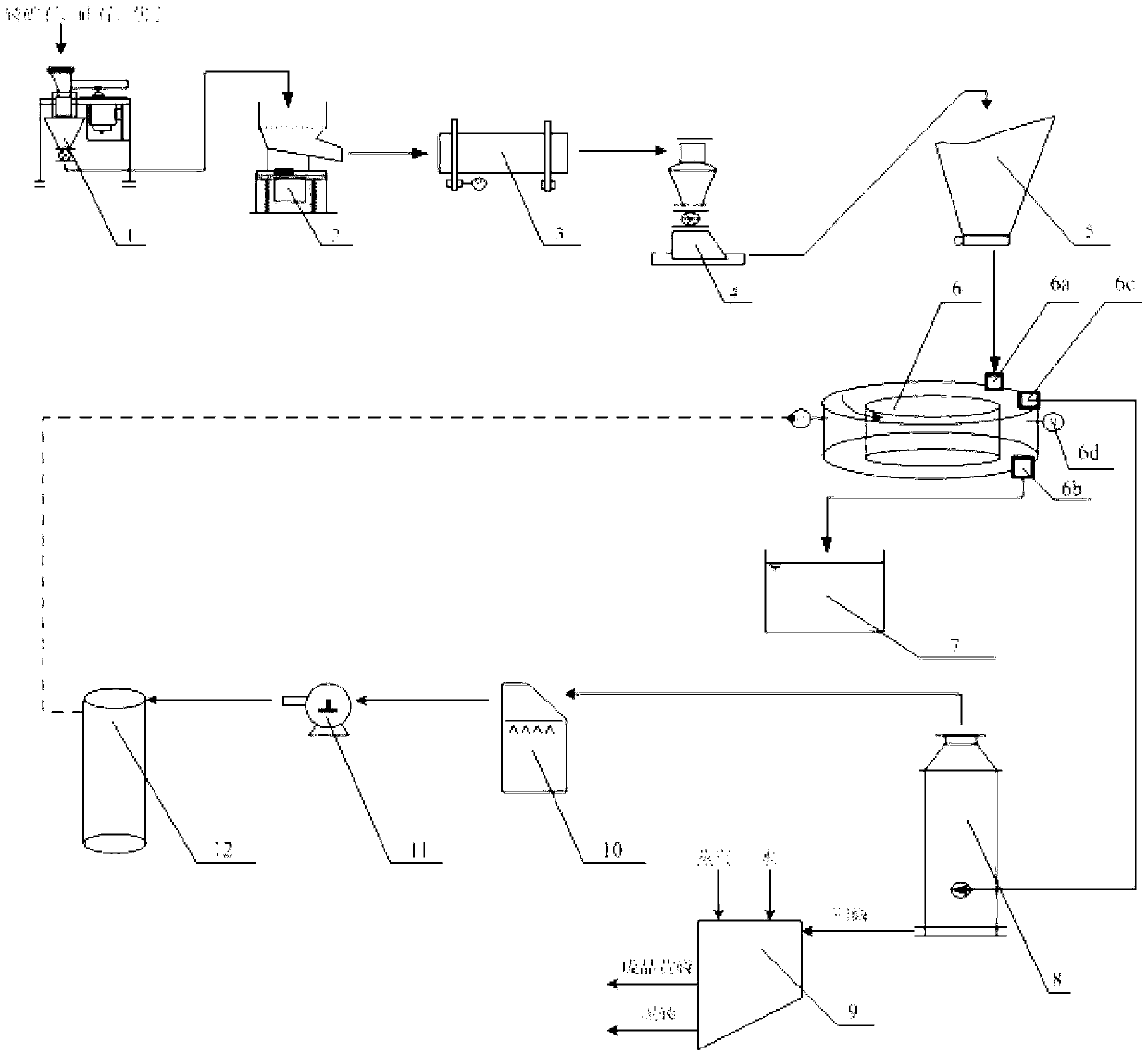

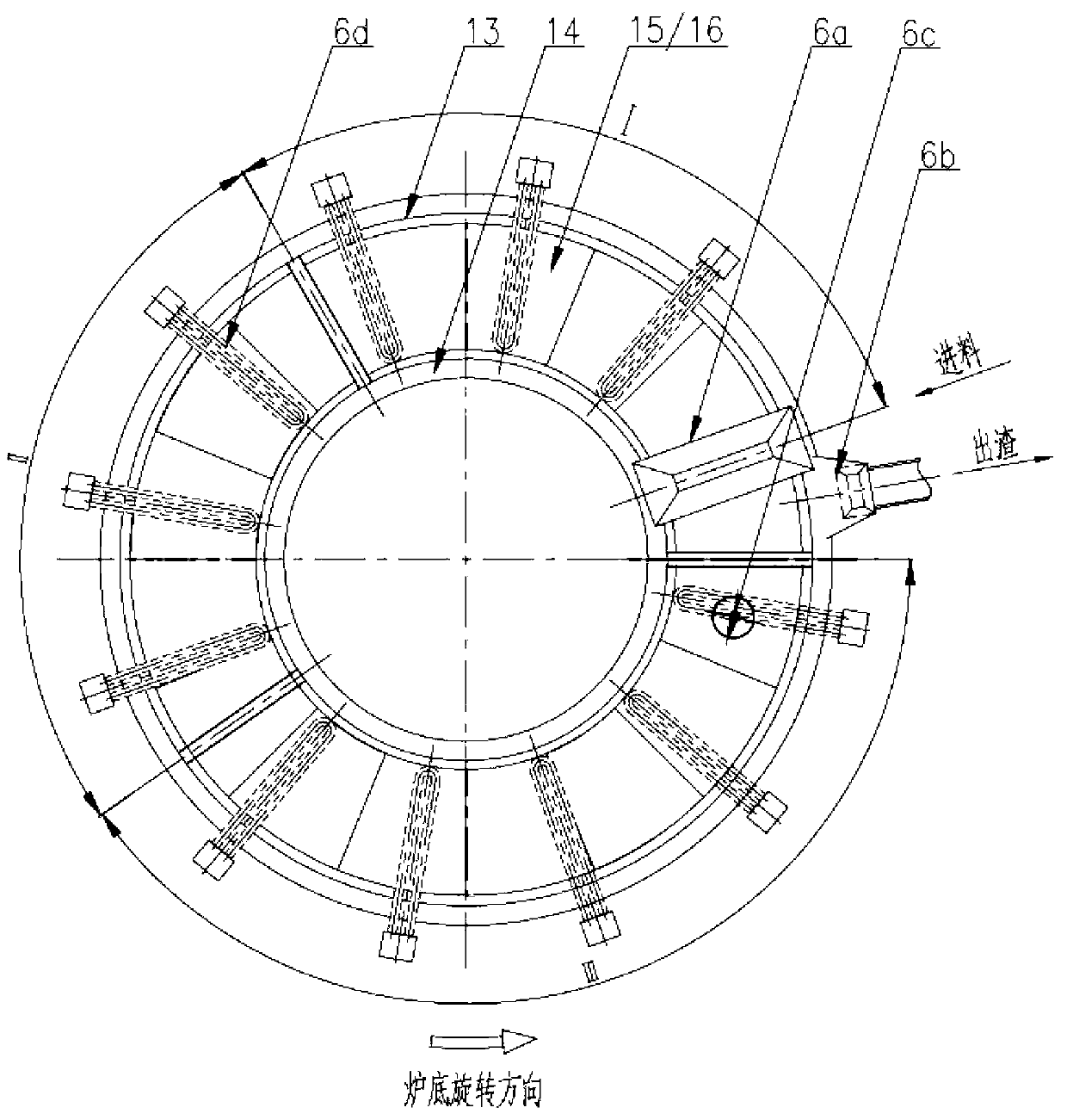

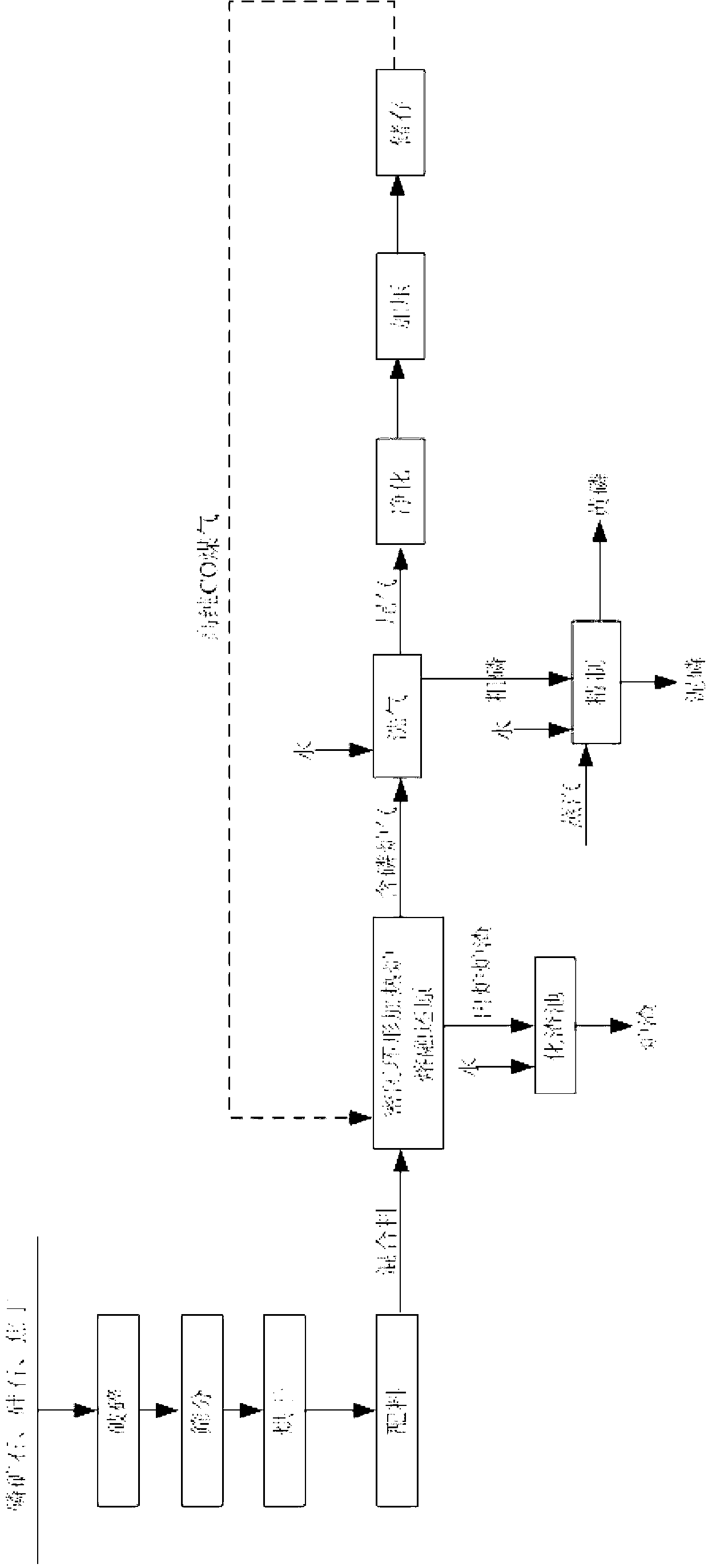

[0036] figure 1 Shown is an equipment for producing yellow phosphorus using a rotary hearth furnace, including a material crusher 1 for crushing raw materials (phosphate rock, silica, coke), a vibrating screener 2 for screening the crushed raw materials, and A dryer 3 for drying raw materials with qualified particle size, the dryer 3 is connected to the metering device 4 through a belt, the metering device 4 is connected to the mixing bin 5, and the mixing bin 5 is connected to the closed annular heating furnace 6; the closed annular heating Furnace 6 is respectively connected with furnace gas treatment tail gas recovery mechanism and slag collection pool 7; furnace gas treatment tail gas recovery mechanism is connected with closed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com