Patents

Literature

31results about How to "High defluorination efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

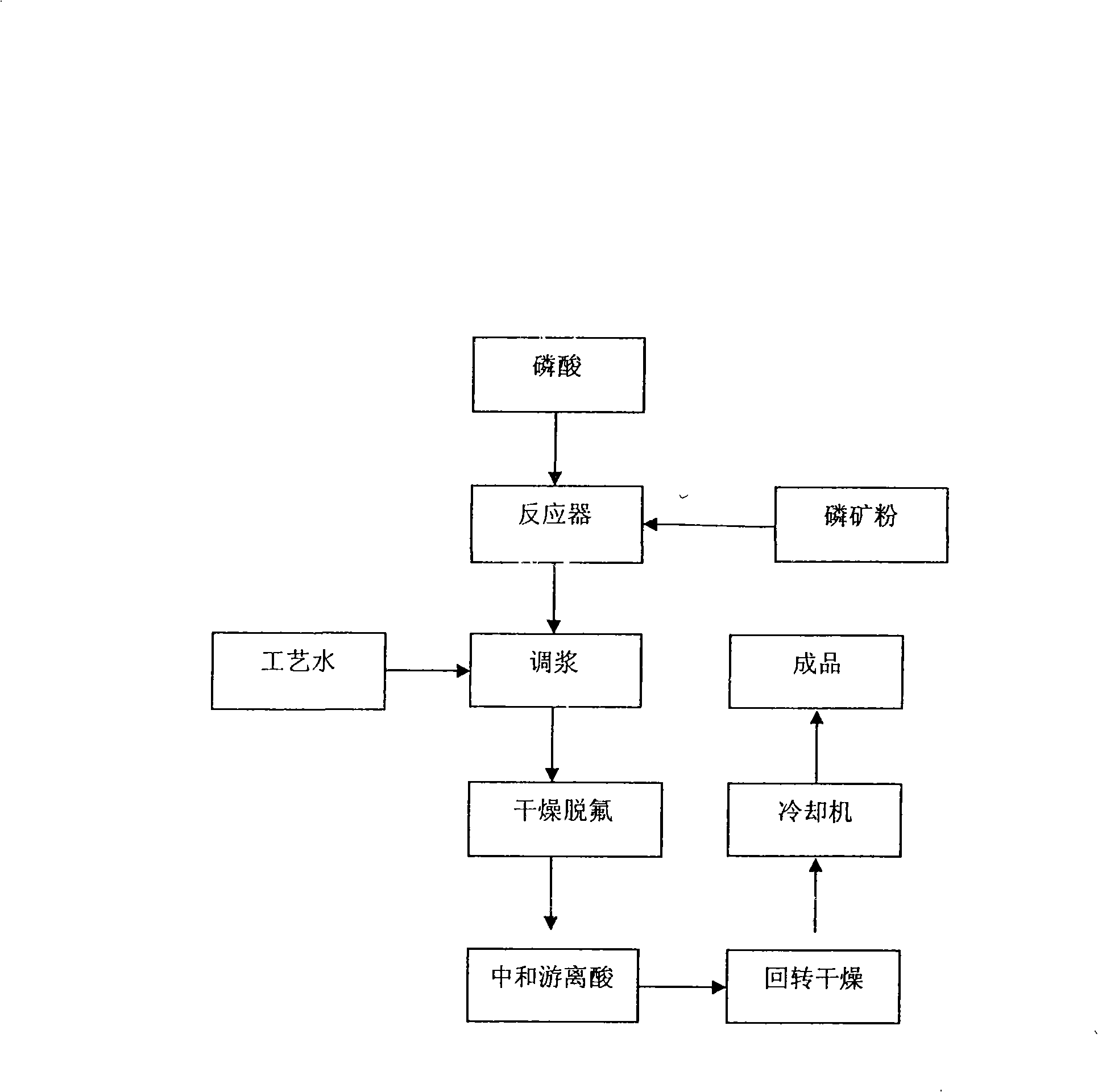

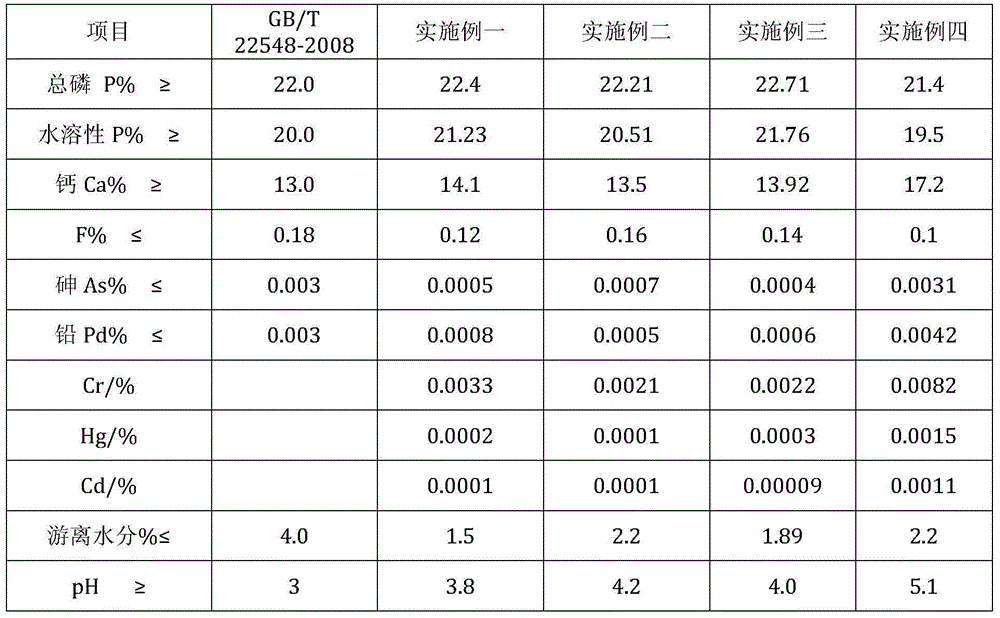

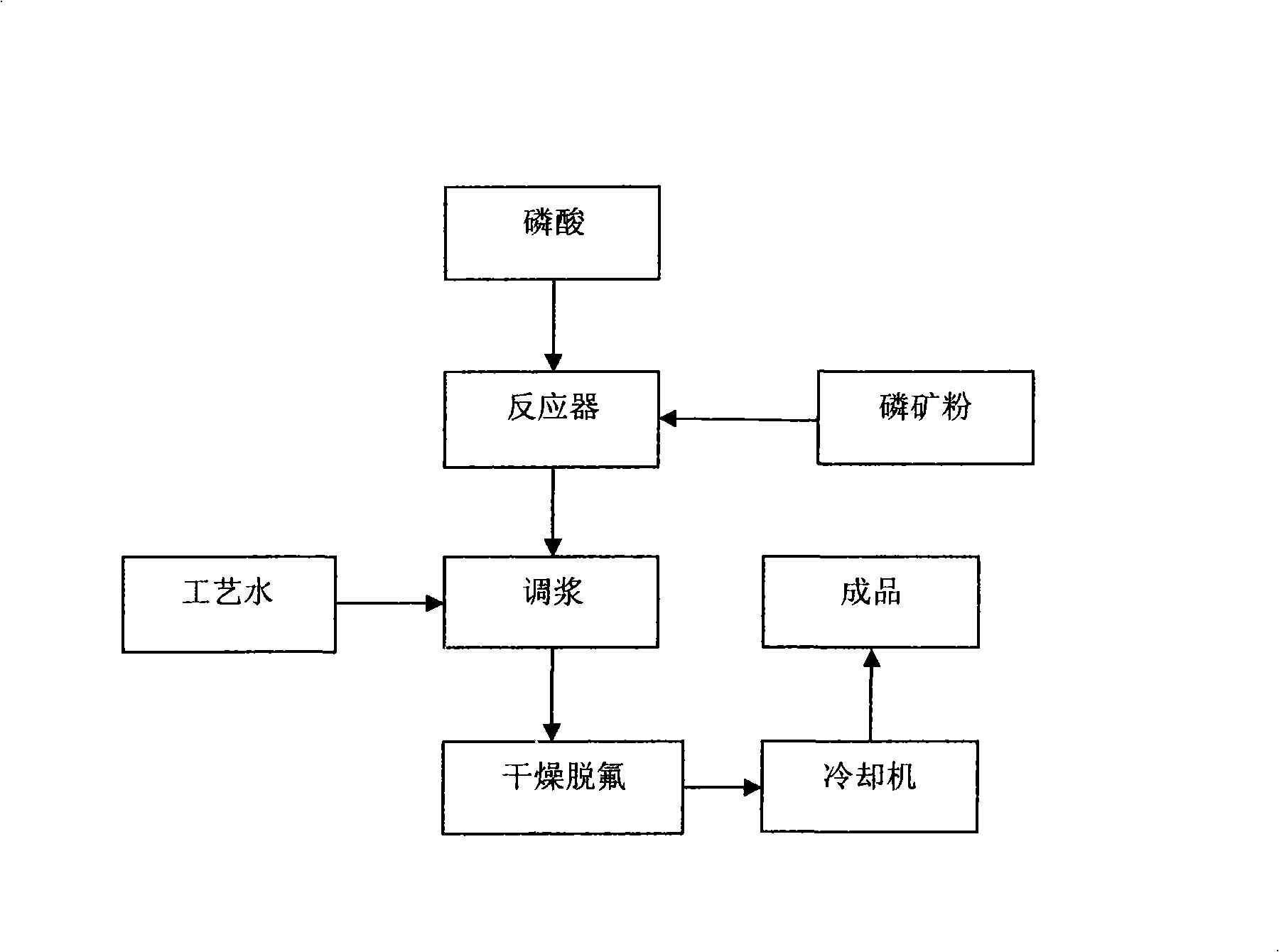

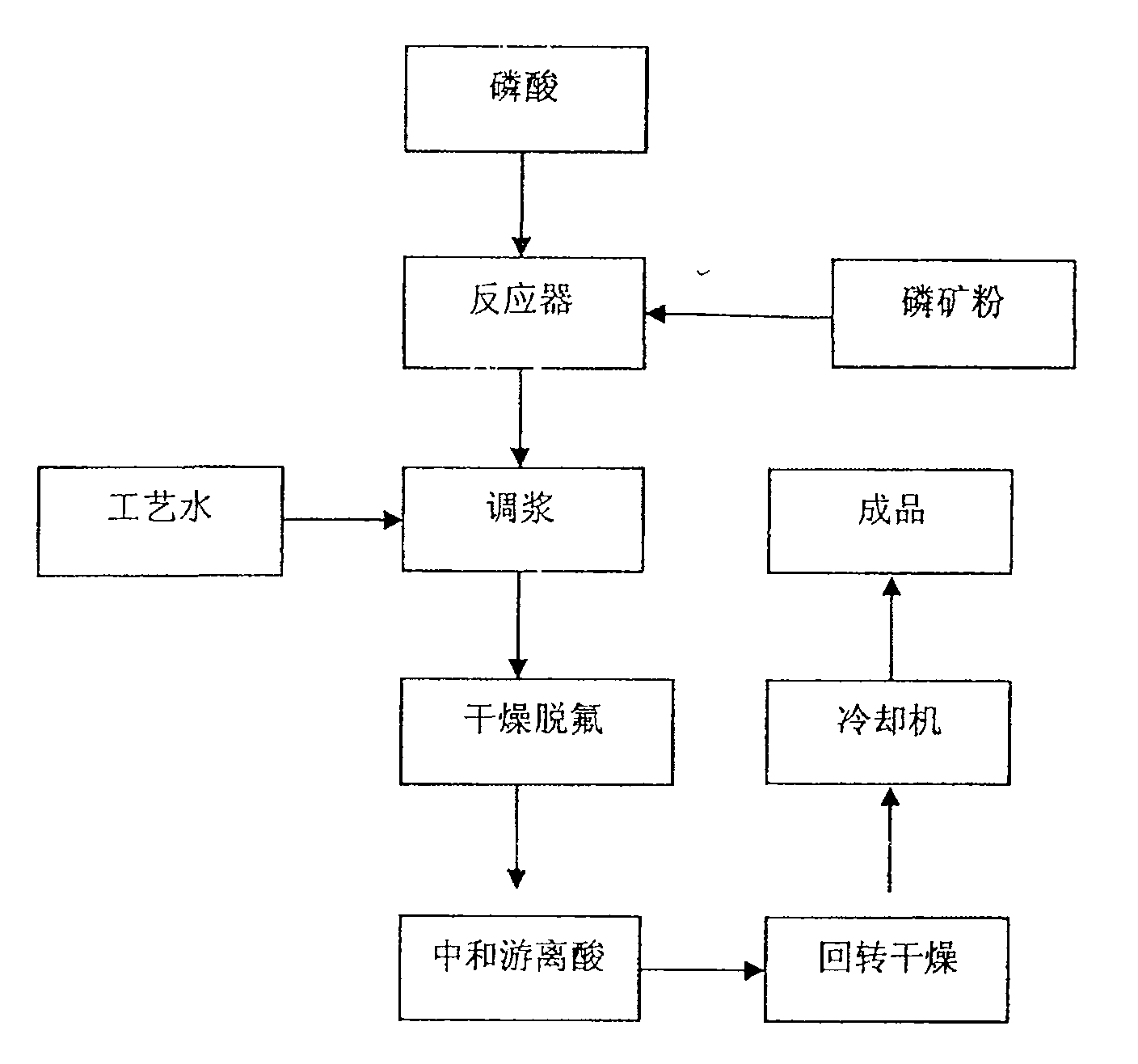

Method for producing feed-grade calcium phosphate

ActiveCN101264873AReduce acidityIncrease cycle ratioPhosphorus compoundsCalcium biphosphatePhosphate

The invention discloses a forage level calcium phosphate production method, comprising that excess phosphoric acid and rock phosphate are added into a reactor to react mixedly; the calcium dihydrogen phosphate material containing fluorine and phosphoric acid; the material is added into a drier to be dried and defluorinated, and the forage level calcium phosphate is made. The forage level calcium phosphate production method has the advantages of fast defluorination, high efficiency, resource saving, low cost, friendly environment, energy saving and emission reducing, which brings the industrial revolution of forge phosphate.

Owner:GUIZHOU CHANHEN CHEM CO LTD

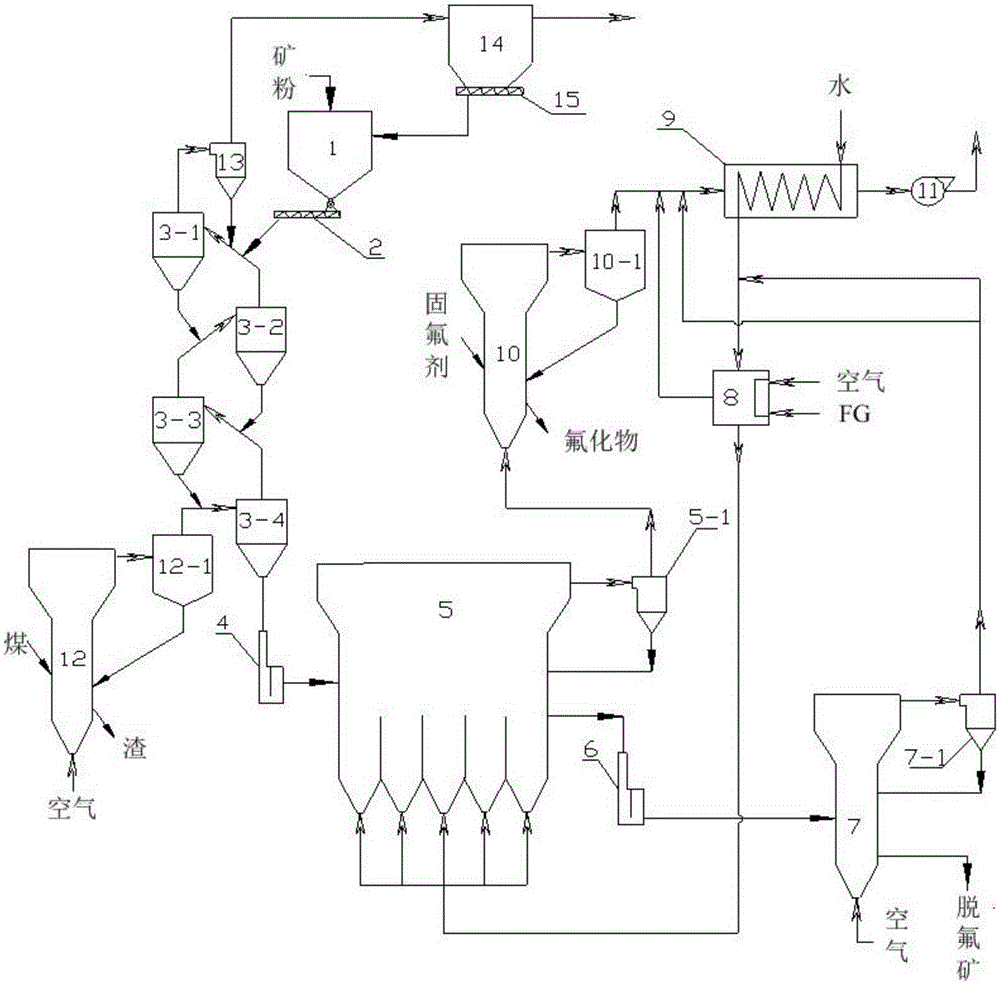

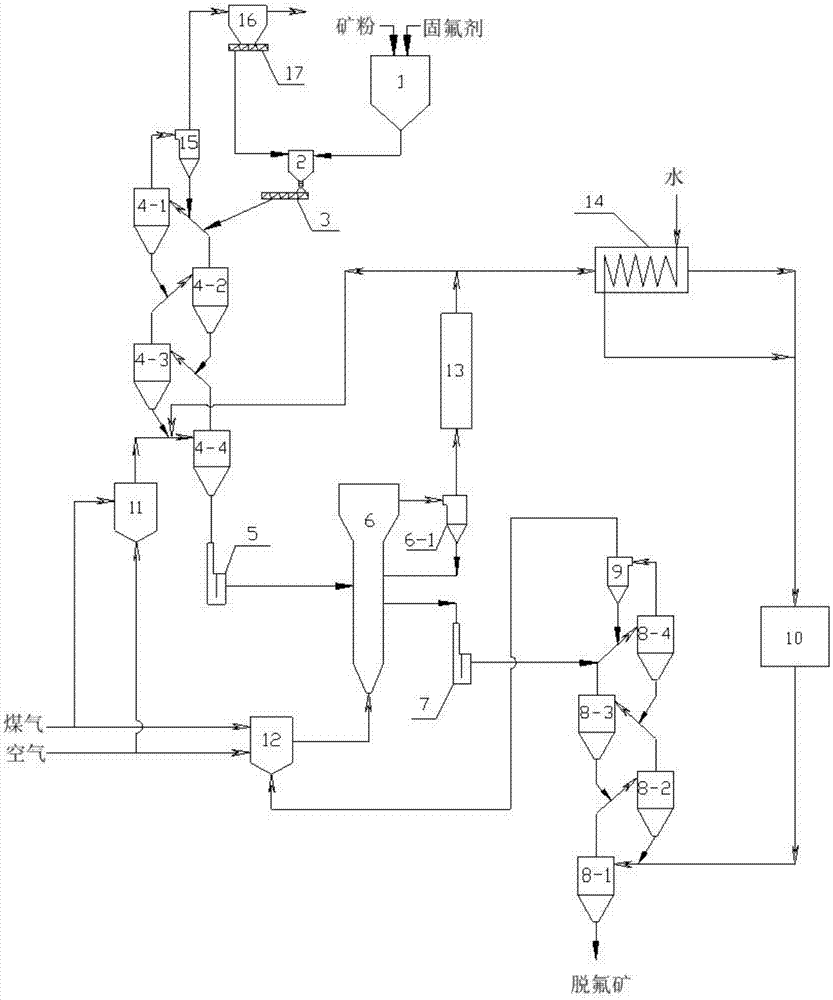

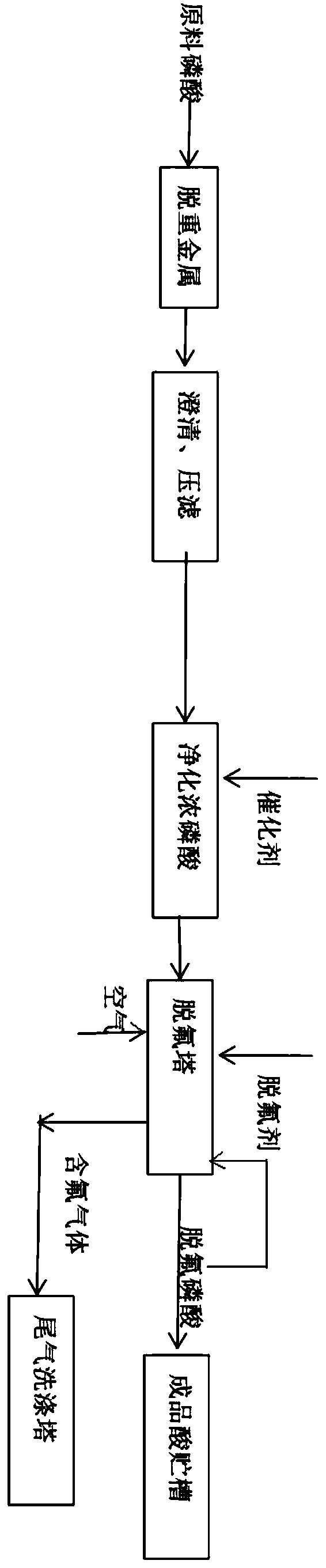

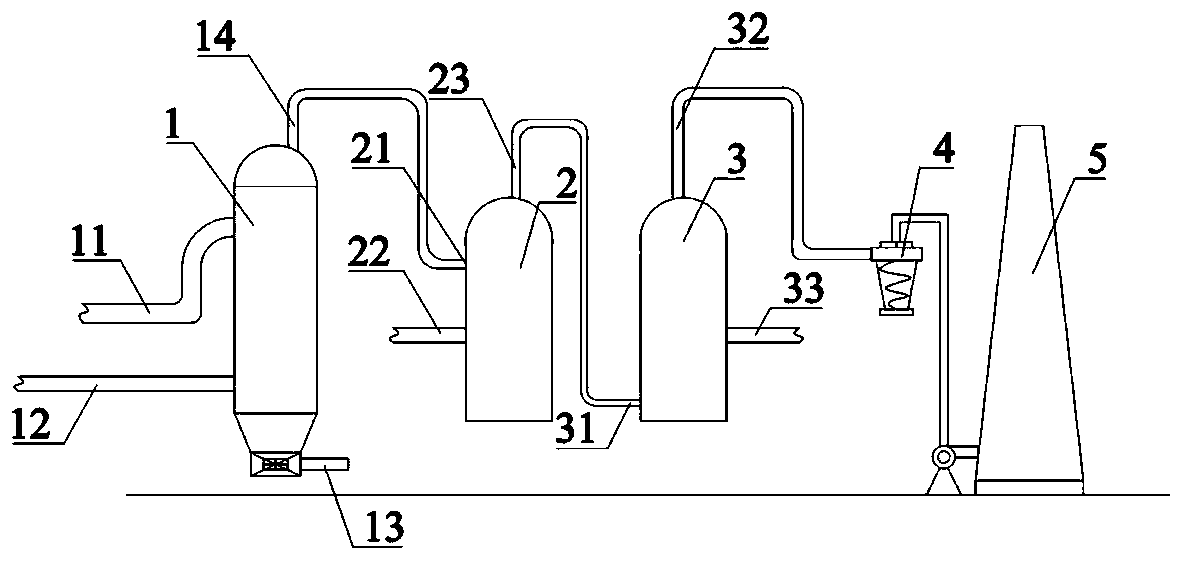

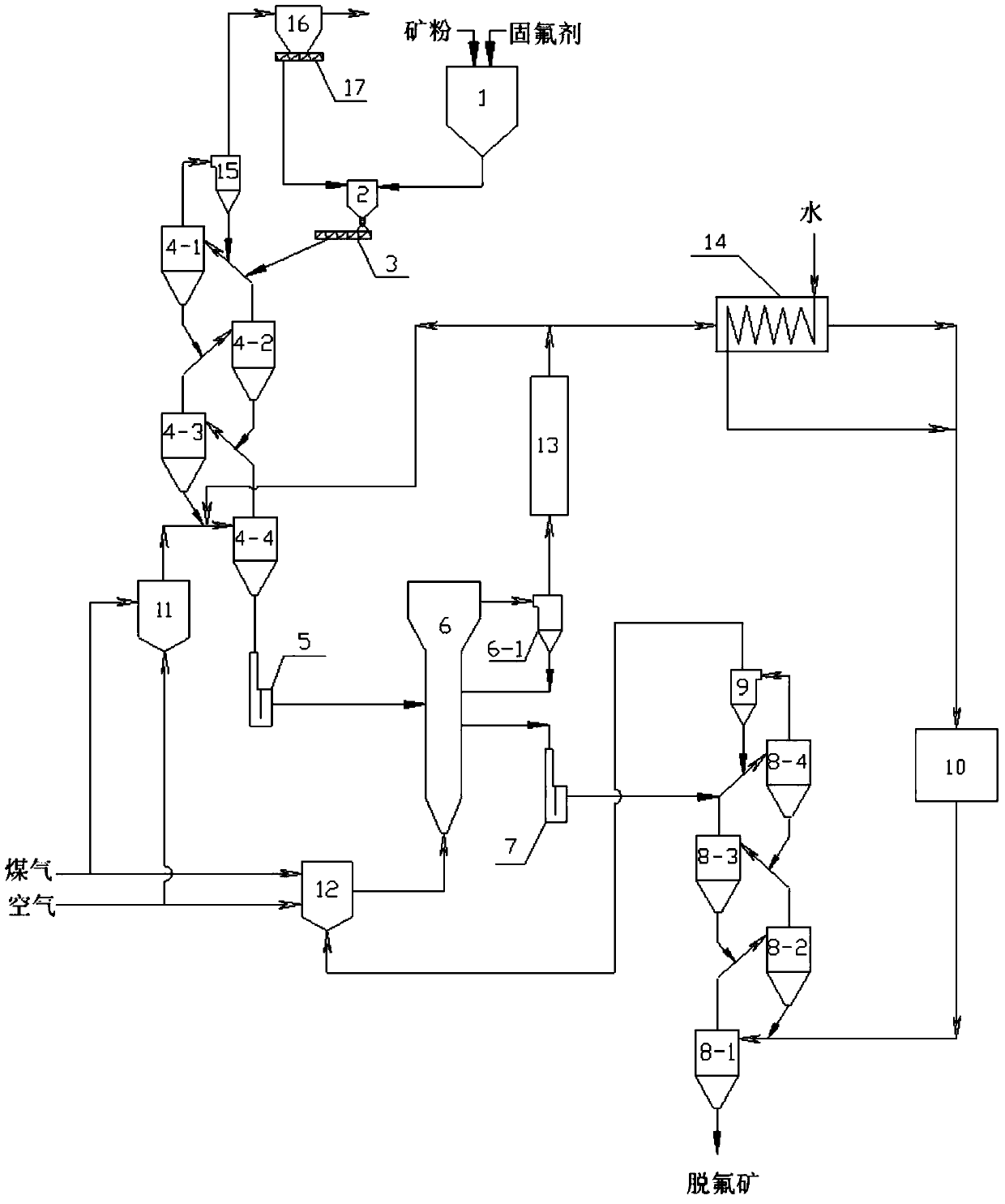

Roasting defluorination device and technology

The invention provides a roasting defluorination device and technology. The roasting defluorination device comprises a feeding system, a mineral powder preheating system, a fluidized-bed roasting system and a vapor preheating system. The fluidized-bed roasting system comprises a fluidized-bed roasting furnace. The feeding system is connected with the mineral powder preheating system. The mineral powder preheating system and the vapor preheating system are connected with the fluidized-bed roasting system. Optionally, the device further comprises a gas absorption system, a cooling system and an air guiding system, the gas absorbing system and the cooling system are connected with the fluidized-bed roasting system, and the air guiding system and the gas absorbing system are connected. The defluorination rate of the roasting defluorination device reaches more than 85%. A solid fluorine fixing agent is used for absorbing fluorine containing tail gas to recycle fluorine resources. Water of a vapor boiler is preheated by heat generated in the high-temperature defluorination tail gas and defluorination material cooling process to generate high-temperature vapor, the heat utilization rate is high, and vapor consumption is low. The roasting process is good in economical efficiency, and the roasting defluorination device and technology are suitable for large-scale continuous industrial production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

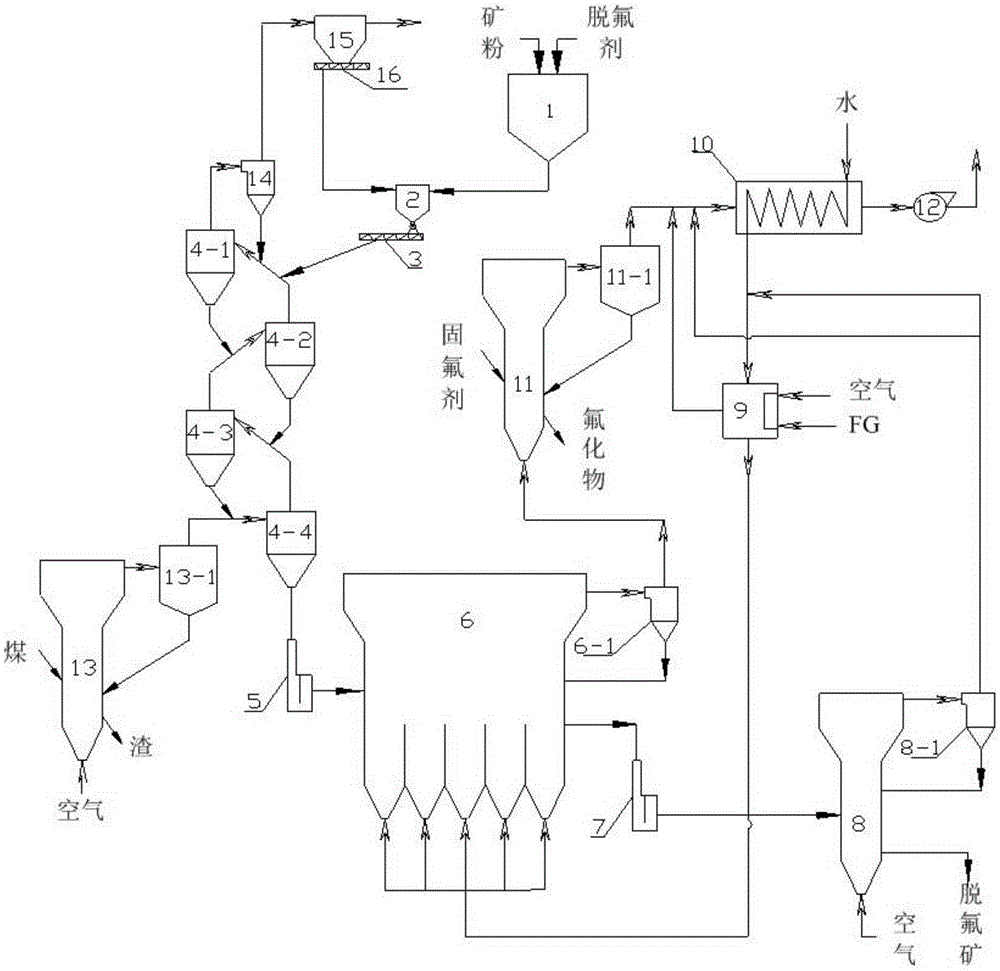

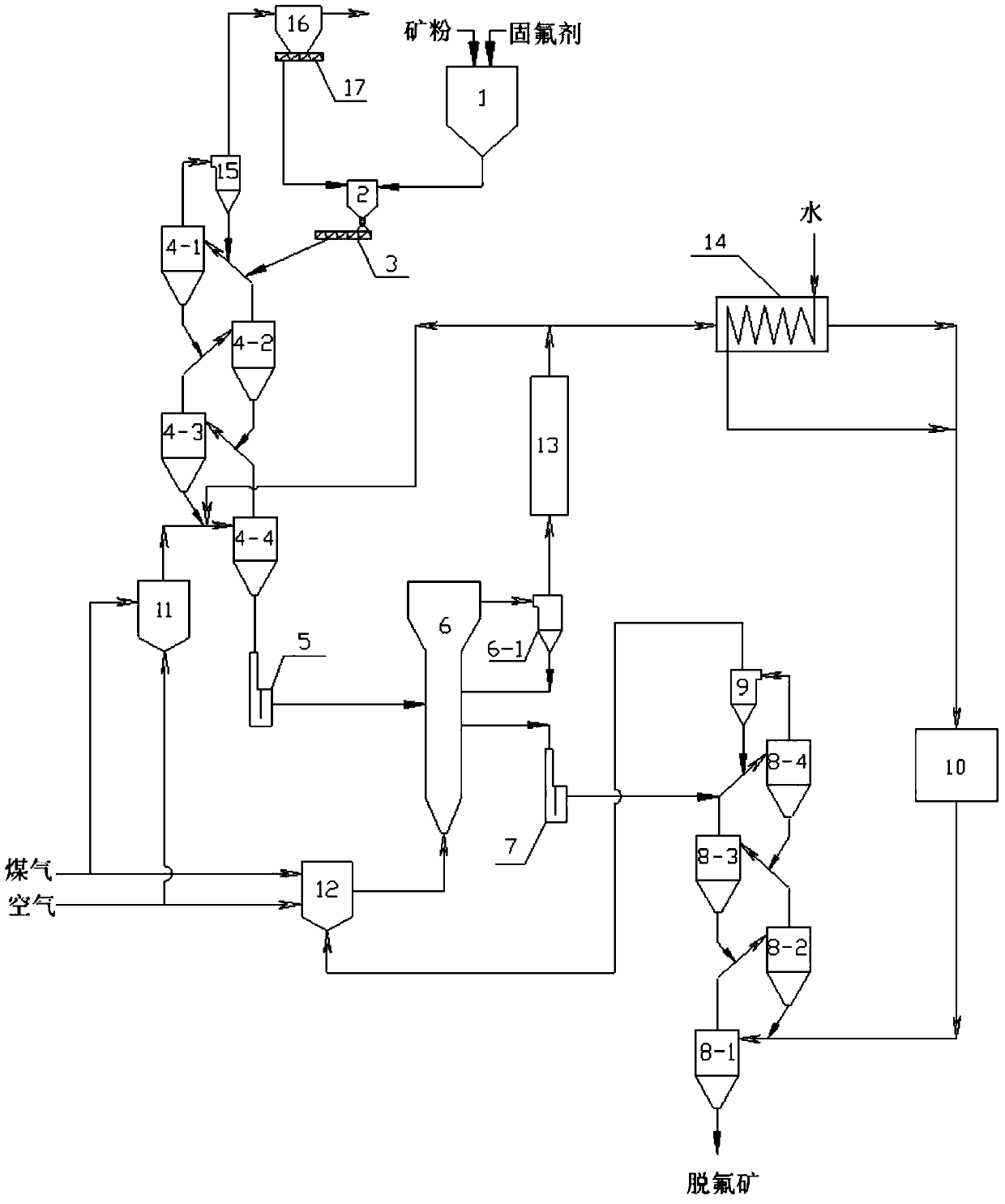

Roasting defluorination device and process

The invention provides a roasting defluorination device and a process. The roasting defluorination device comprises a material mixing system, a mixture preheating system, a water vapor preheating system and a fluidized-bed roasting system. The fluidized-bed roasting system comprises a fluidized-bed roaster. The material mixing system is connected with the mixture preheating system. The mixture preheating system and the water vapor preheating system are connected with the fluidized-bed roasting system. Optionally, the device further comprises a gas absorbing system, a cooling system and an induced draught system. The gas absorbing system and the cooling system are connected with the fluidized-bed roasting system, and the induced draught system is connected with the gas absorbing system. According to the device, in-situ defluorination can be achieved, the fluorine removal rate reaches 95% or above, and the defluorination rate reaches 90% or above. High-temperature water vapor is produced through high-temperature defluorination tail gas, high-temperature smoke generated by a combustion chamber and heat generated during defluorination material cooling, and the heat utilization rate is high. Water vapor consumption is low, the roasting process is good in economical efficiency, and the roasting defluorination device and the process are suitable for large-scale continuous industrial production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

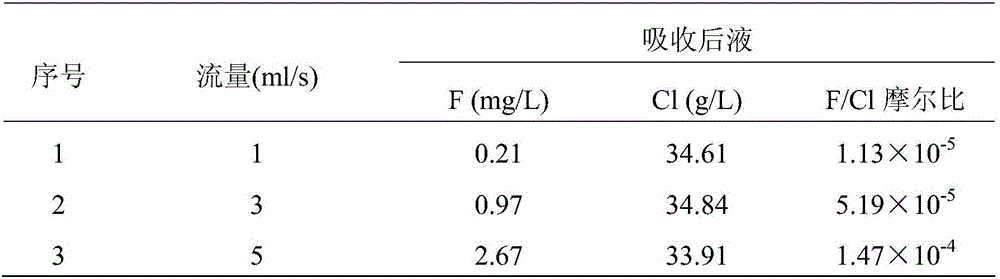

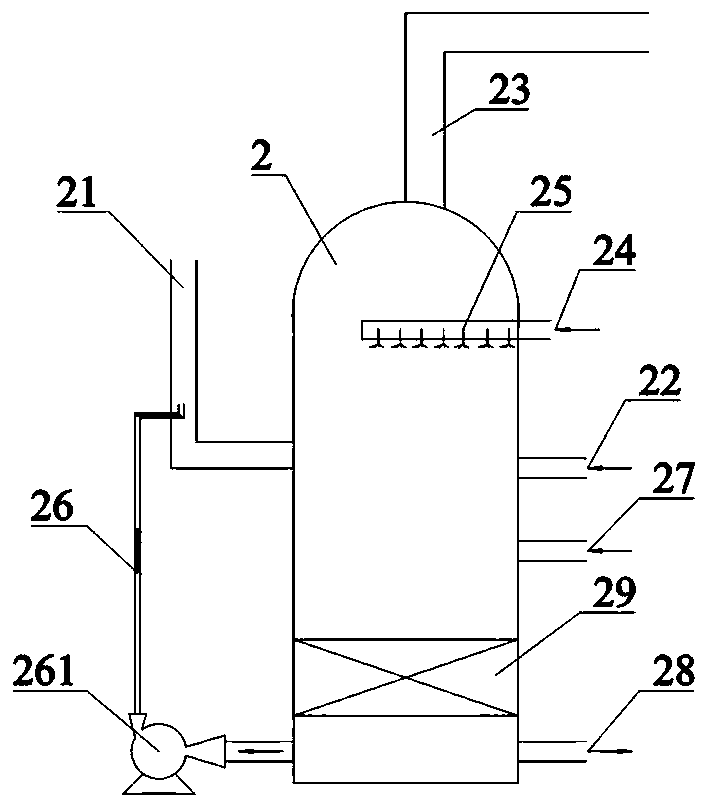

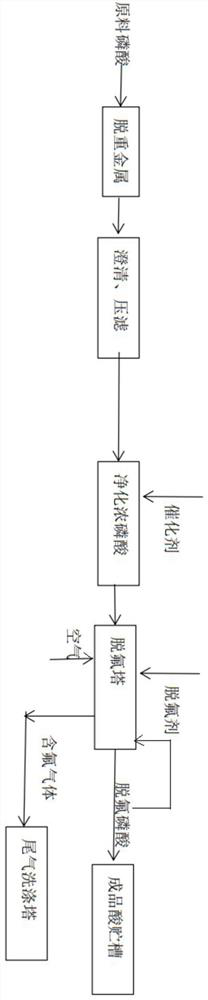

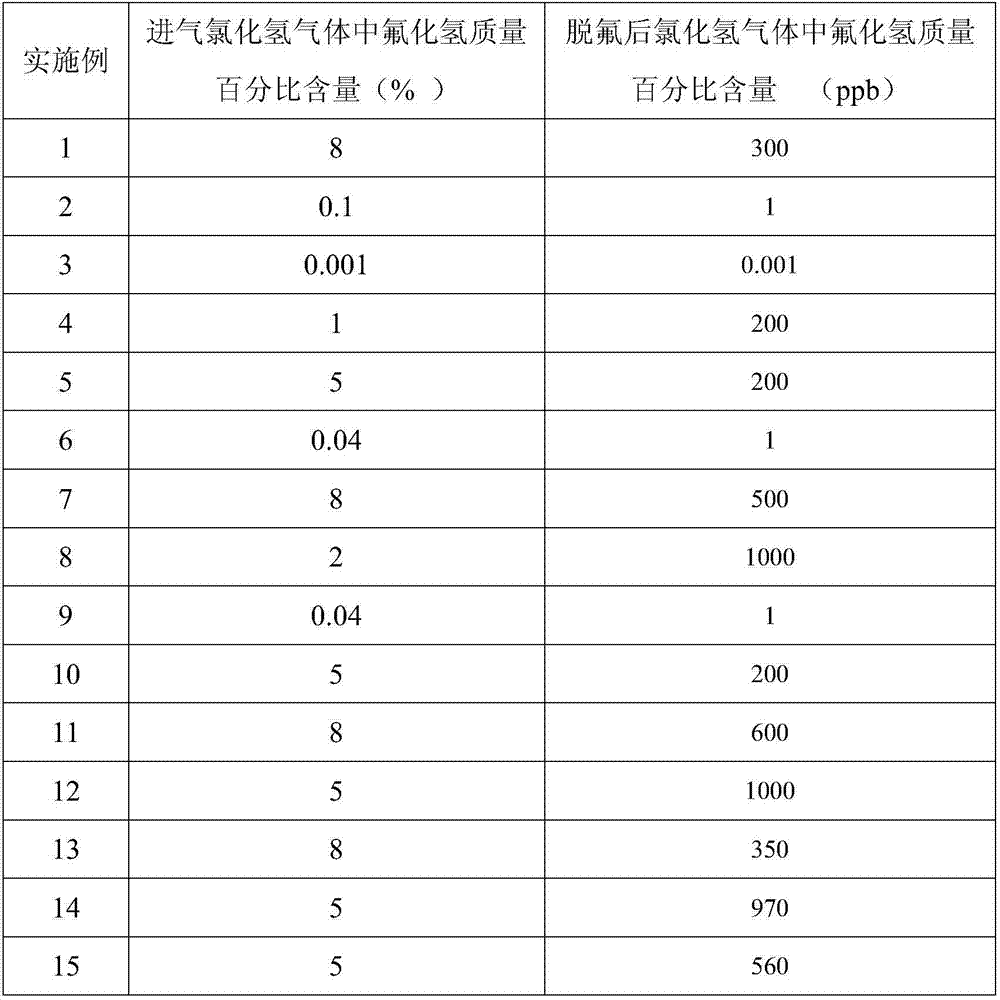

Method for removing and recycling hydrogen fluoride from hydrogen chloride gas

InactiveCN106495100ARealize recycling of resourcesSimple processChlorine/hydrogen-chloride purificationHydrogen fluorideSorbentHydrochloric acid

Disclosed is a method for removing and recycling hydrogen fluoride from hydrogen chloride gas. The method comprises drying the hydrogen chloride gas containing hydrogen fluoride, and then through calcium / magnesium / aluminum oxide / chloride / hydroxide / carbonate as absorbent, absorbing the hydrogen fluoride contained in the hydrogen chloride gas to obtained defluorinated hydrogen chloride gas and loaded absorbent, wherein the defluorinated hydrogen chloride gas can be directly put into use or absorbed inside water to produce hydrochloric acid for utilization; adding H2SO4 into the loaded absorbent to converted fluorine inside the loaded absorbent into HF, and increasing the temperature to volatize the HF from the reaction system for producing fluorine compounds and further achieving the effect of removing hydrogen fluoride as well as recycling or fluorine resources. The method for removing and recycling the hydrogen fluoride from the hydrogen chloride gas has the advantages of being simple in process and operation, low in production cost, economic, high in efficiency, environmentally-friendly and high in defluorination efficiency, thereby being applicable to industrial application.

Owner:CENT SOUTH UNIV

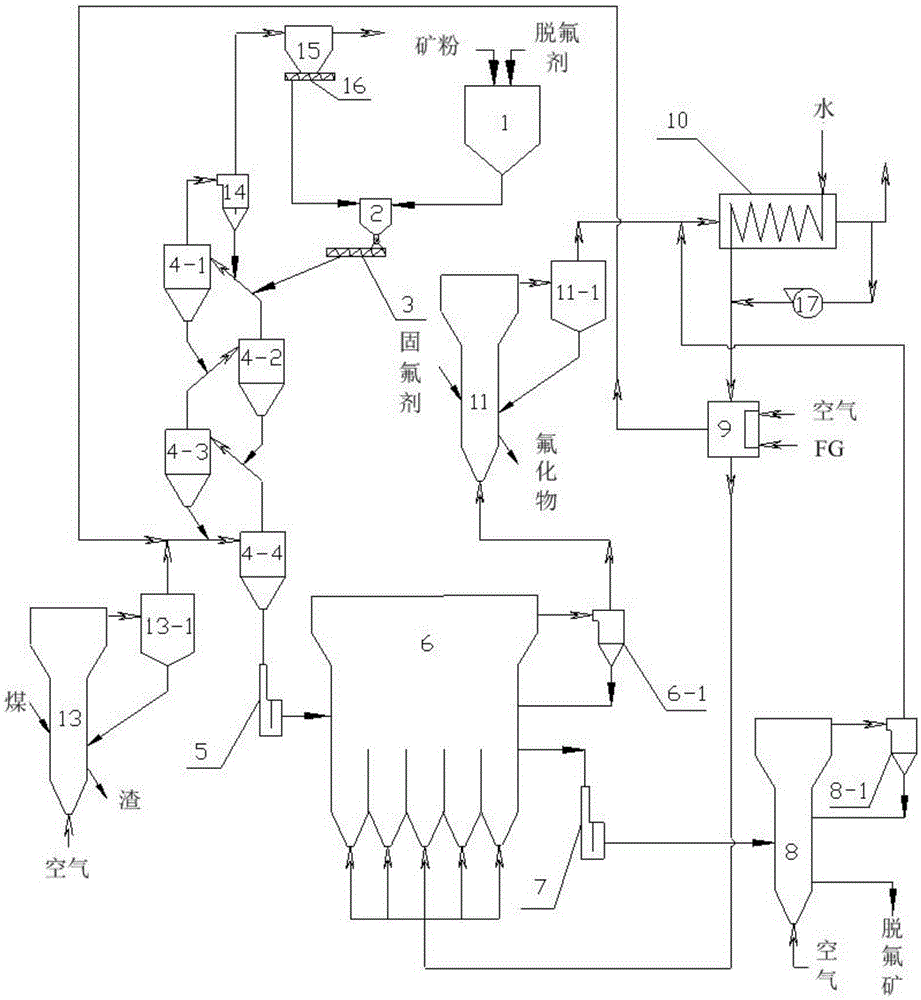

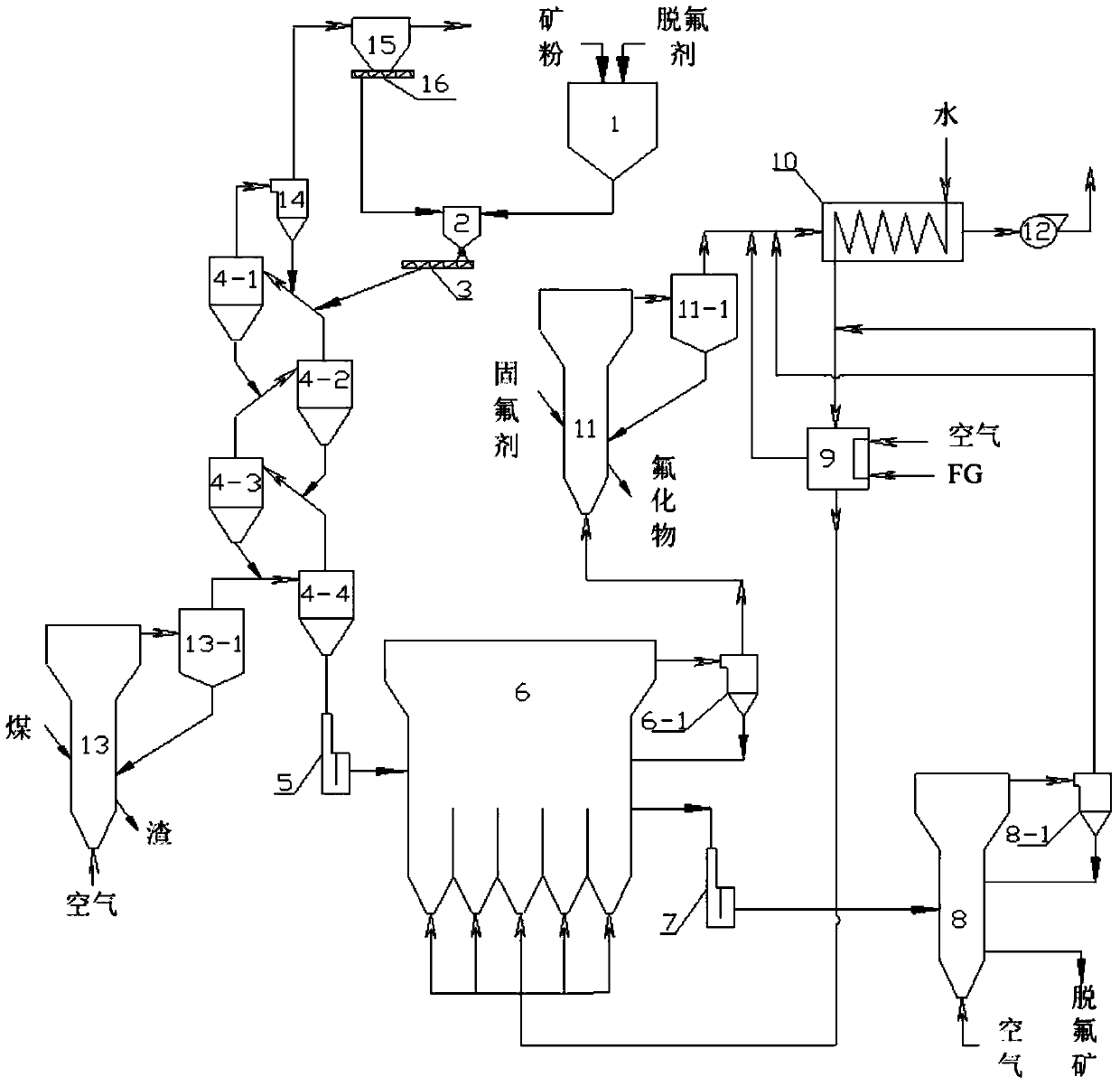

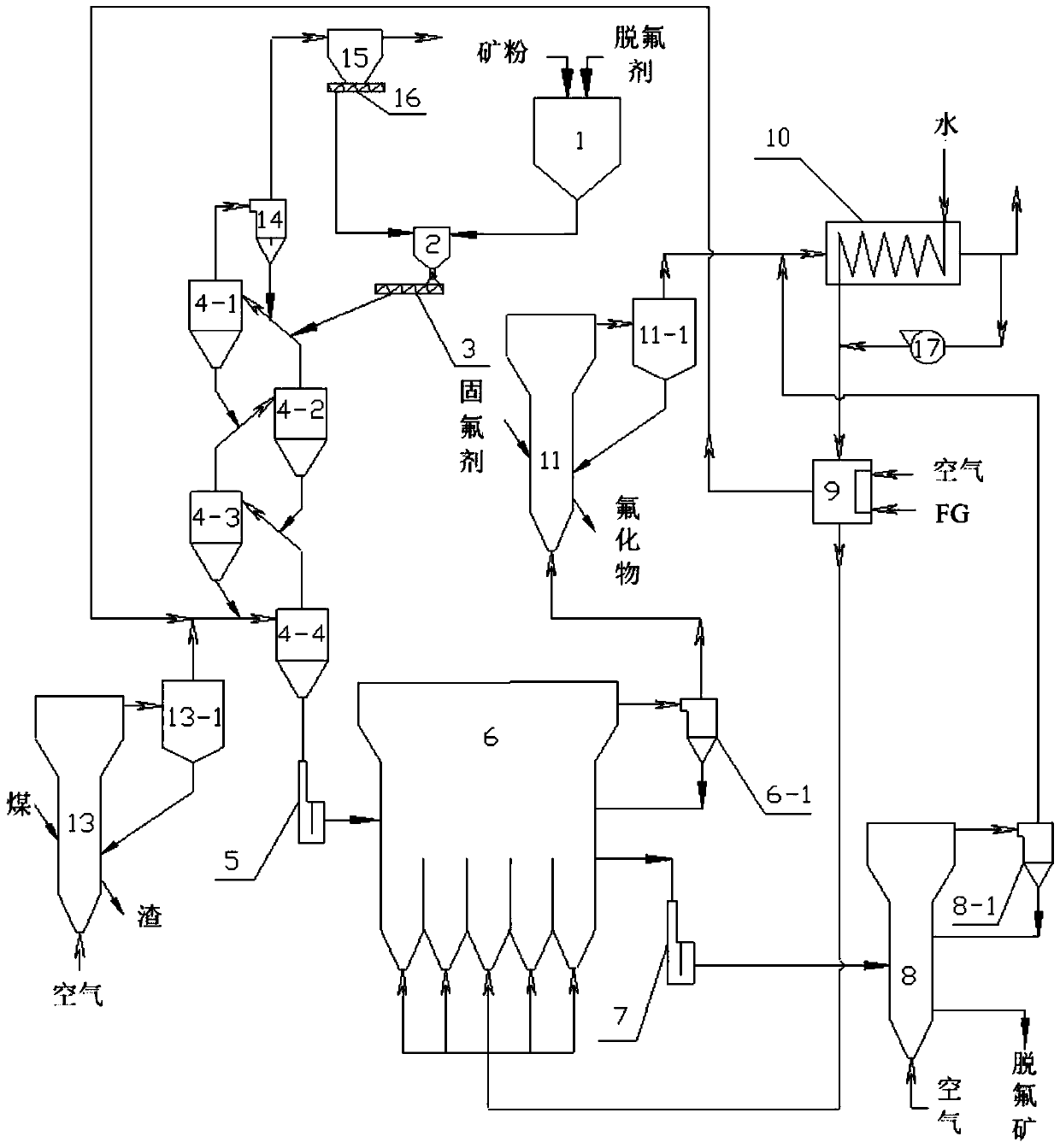

Defluorination calcination device and technology for minerals containing lithium

The invention provides a defluorination calcination device and technology for minerals containing lithium. The defluorination calcination device comprises a mineral powder preheating system, a vapor preheating system, a fluidized bed calcination system and a vapor circulating system, wherein the fluidized bed calcination system comprises a fluidized bed calcination furnace; the mineral powder preheating system and the vapor preheating system are separately connected with the fluidized bed calcination system; the vapor circulating system comprises a steam boiler and a compressor; an air inlet of the steam boiler is connected with the fluidized bed calcination system; a water outlet and a flue gas outlet of the steam boiler are separately connected with an air inlet of the compressor; the air outlet of the compressor is connected with the vapor preheating system; and optionally, the defluorination calcination device also comprises a feeding system, a gas absorbing system and a cooling system. The defluorination rate of the defluorination calcination device achieves 85% or above, and the calcination process is good in economical efficiency; the circulation of a part of vapor is adopted, so that the vapor consumption is reduced; and besides, the cooling of high-temperature defluorination materials is utilized to preheat circulating vapor to generate high-temperature vapor, and the heat utilization ratio is high.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

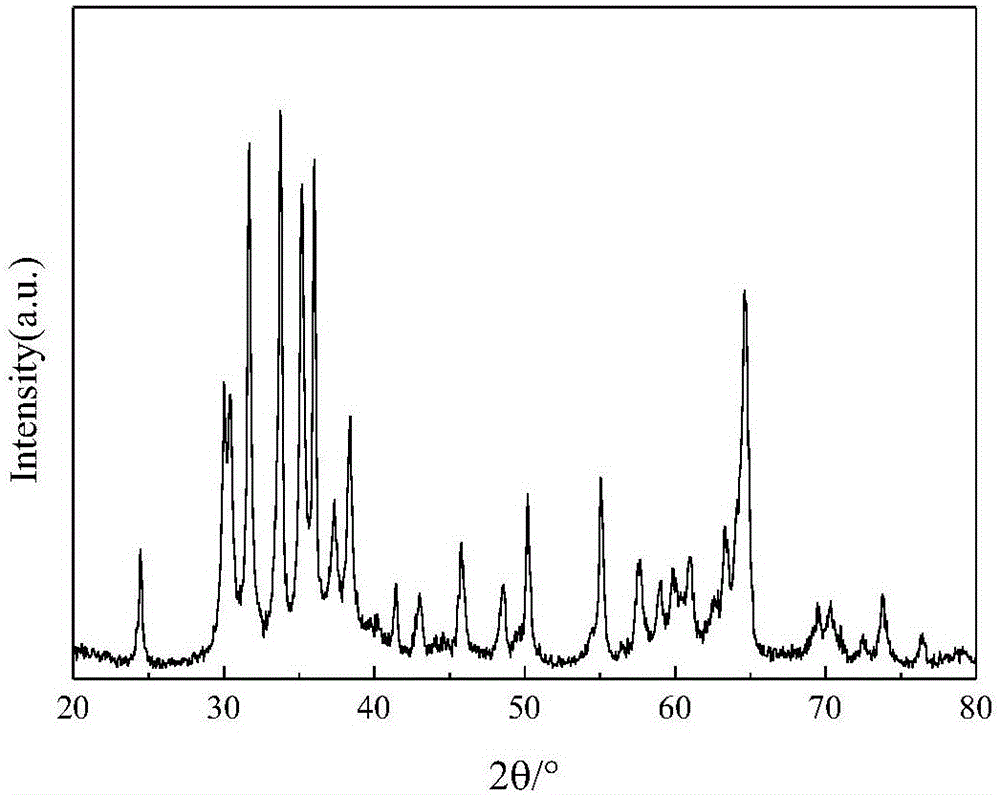

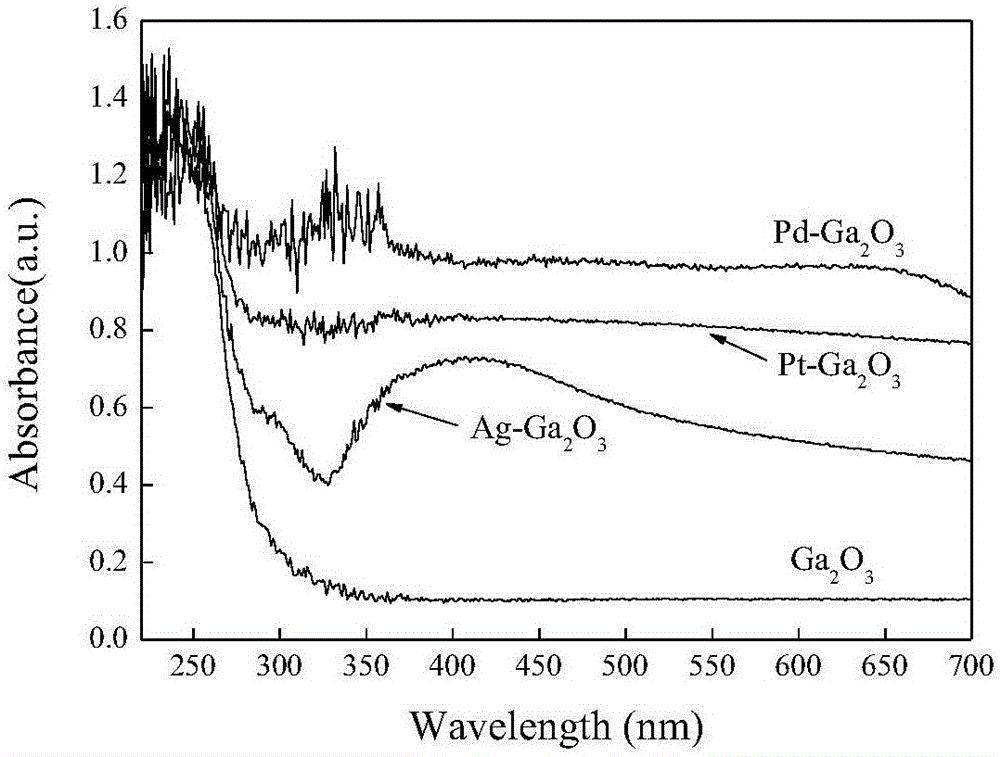

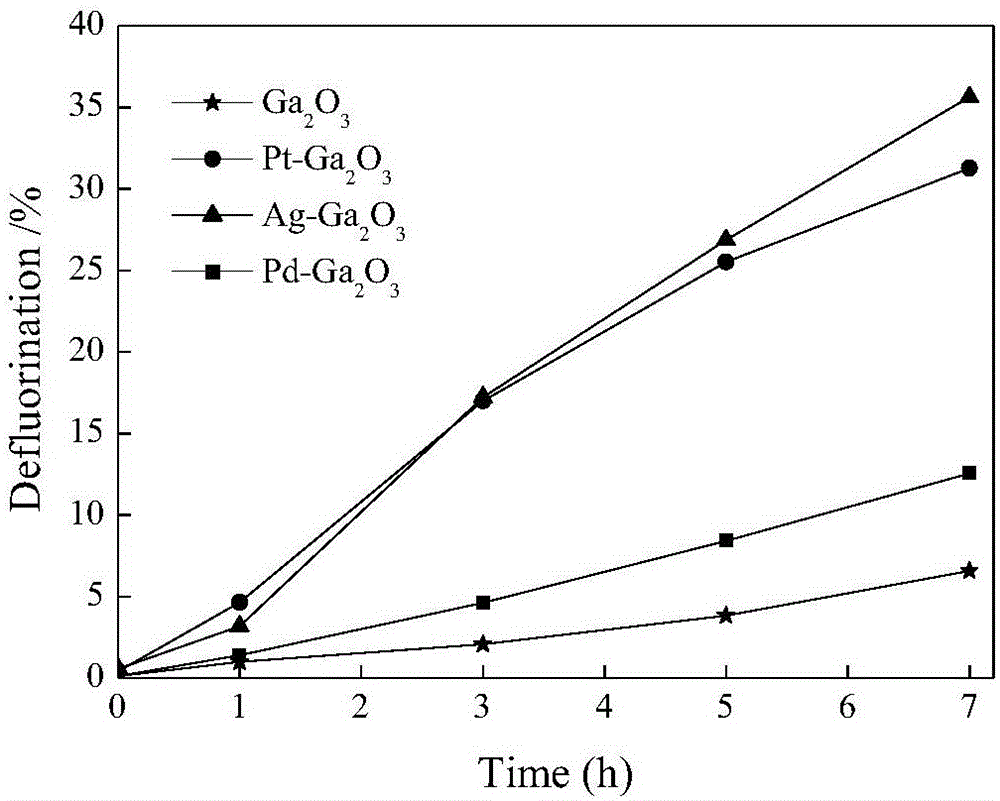

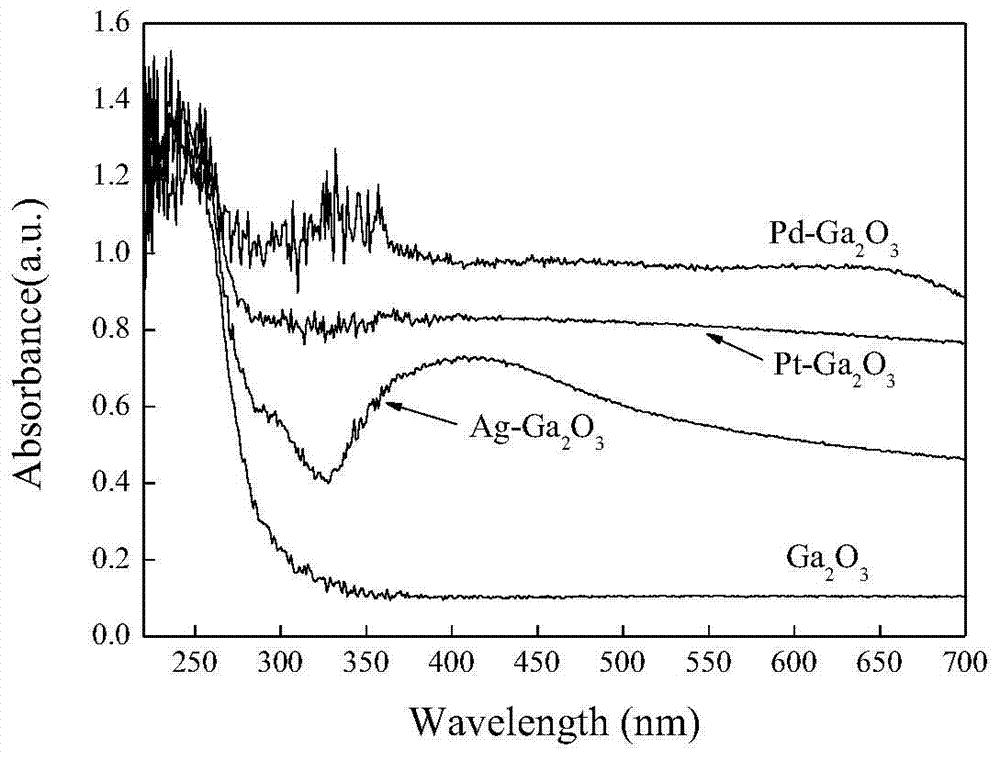

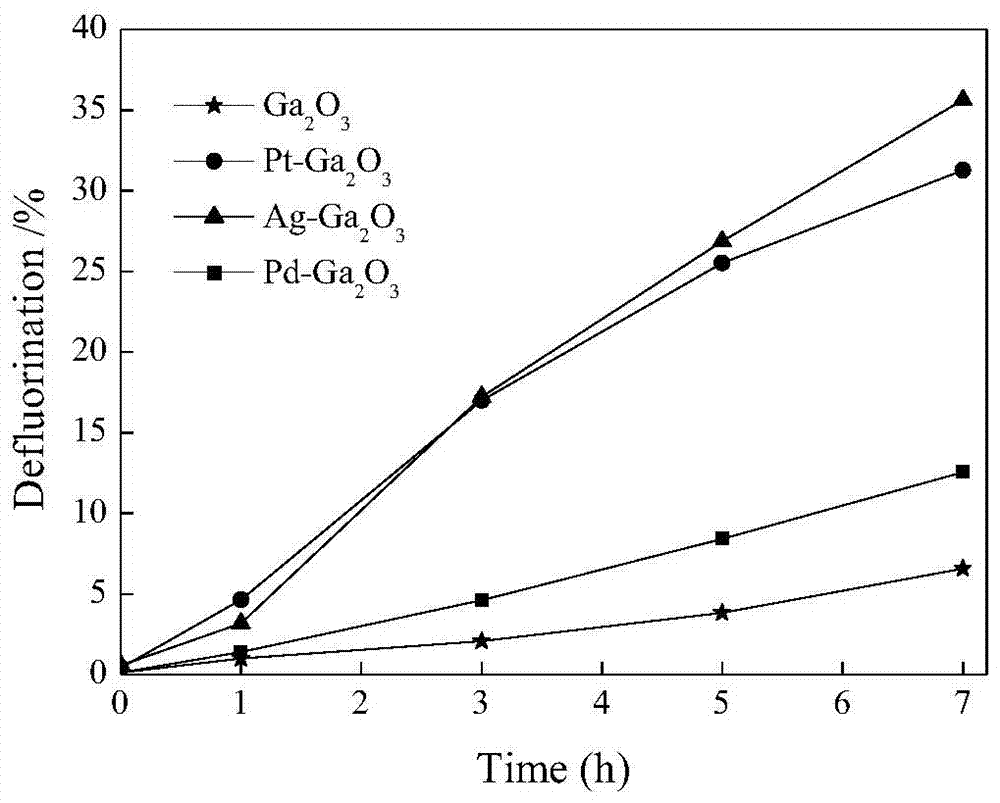

Method for photocatalytic degradation of PFOA (perfluorooctanoic acid) in water through noble-metal-doped gallium oxide

ActiveCN105060389AHigh defluorination efficiencyImprove light absorption abilityWater/sewage treatment by irradiationWater contaminantsPhotocatalytic degradationChemistry

The invention belongs to the technical field of water treatment, and particularly relates to a method for photocatalytic degradation of PFOA (perfluorooctanoic acid) in water through noble-metal-doped gallium oxide. The method comprises steps as follows: preparation of a noble-metal-doped gallium oxide catalyst and photocatalytic degradation of the PFOA through the noble-metal-doped gallium oxide catalyst. Specifically, a noble metal salt solution is added to a gallium oxide suspension for full and even mixing, then a reducing salt solution is added dropwise, metal particles are reduced and loaded onto the surface of gallium oxide, the noble-metal-doped gallium oxide photocatalyst is prepared, and then the PFOA is degraded in the presence of ultraviolet light by the aid of the photocatalyst, so that the PFOA in the water is removed. The method has the advantages that the photocatalyst preparation method is simple, the PFOA is degraded under normal temperature and normal pressure conditions, no complex device is required, and the degradation efficiency is high.

Owner:GUANGXI UNIV

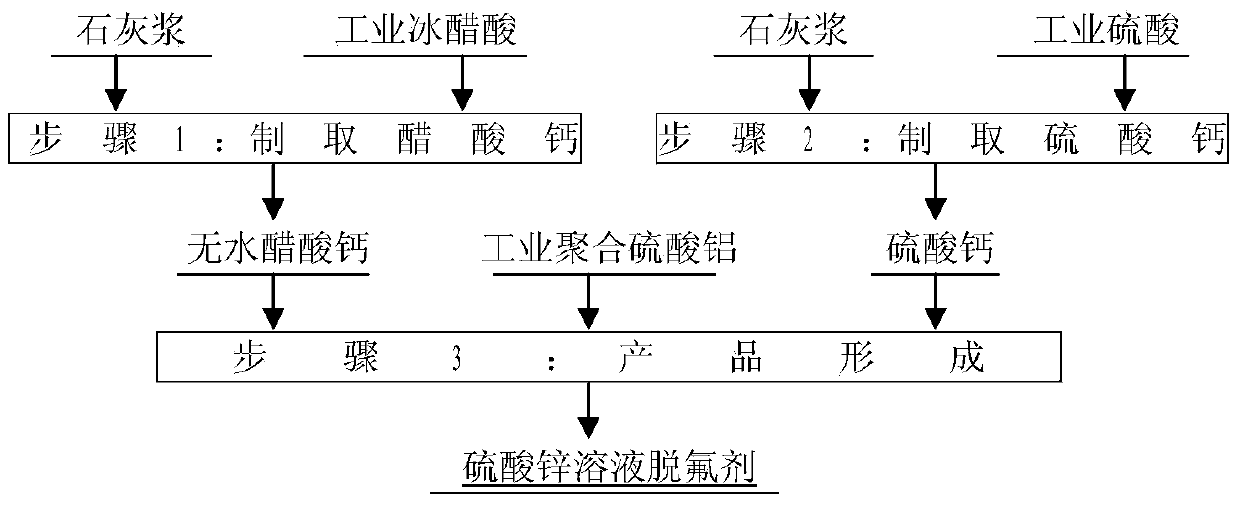

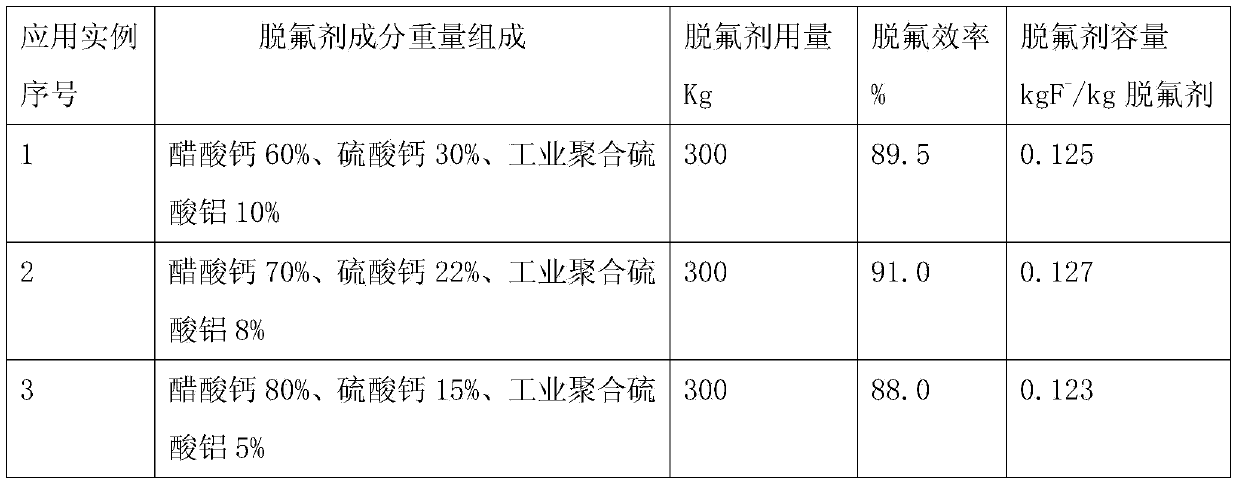

Method for preparing zinc sulfate solution de-fluorination agent

InactiveCN103725883ASimple production processLarge capacityPhotography auxillary processesProcess efficiency improvementCalcium Acetate MonohydrateAcetic acid

The invention discloses a method for preparing a zinc sulfate solution de-fluorination agent, which comprises the following steps: 99% glacial acetic acid reacts with lime slurry to produce a calcium acetate solution, the calcium acetate solution is evaporated and concentrated to obtain calcium acetate monohydrate, and the calcium acetate monohydrate is dried to obtain anhydrous calcium acetate; industrial sulphuric acid reacts with lime slurry to produce calcium sulfate dehydrate, and the calcium sulfate dehydrate is dried to obtain calcium sulfate; 60-80% of anhydrous calcium acetate, 15-30% of calcium sulfate and 5-10% of industrial polyalumi rlillm sulfate are mixed by mass percent, then crushed and packaged, so that the zinc sulfate solution de-fluorination agent is obtained. The de-fluorination agent prepared through the method is simple in production process, calcium of the de-fluorination agent exists in the soluble matter form, the de-fluorination efficiency is high, the high capability is realized, and the cost is low.

Owner:LAIBIN CHINA TIN SMELTING

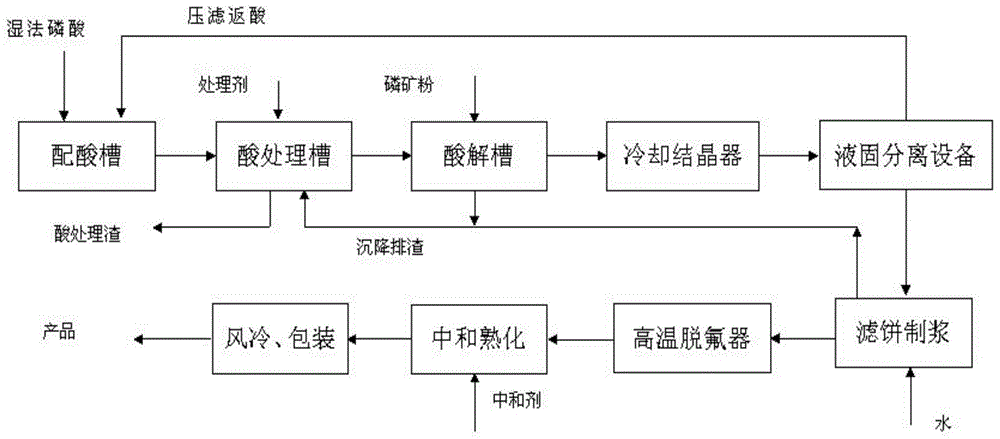

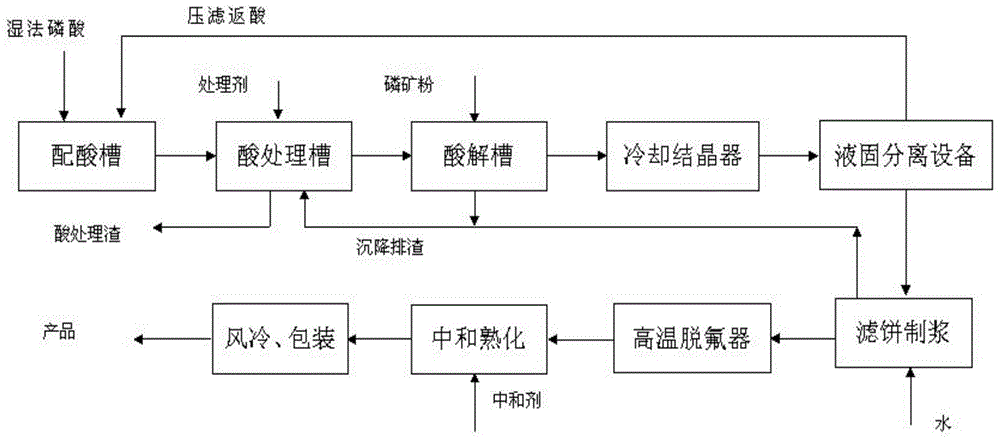

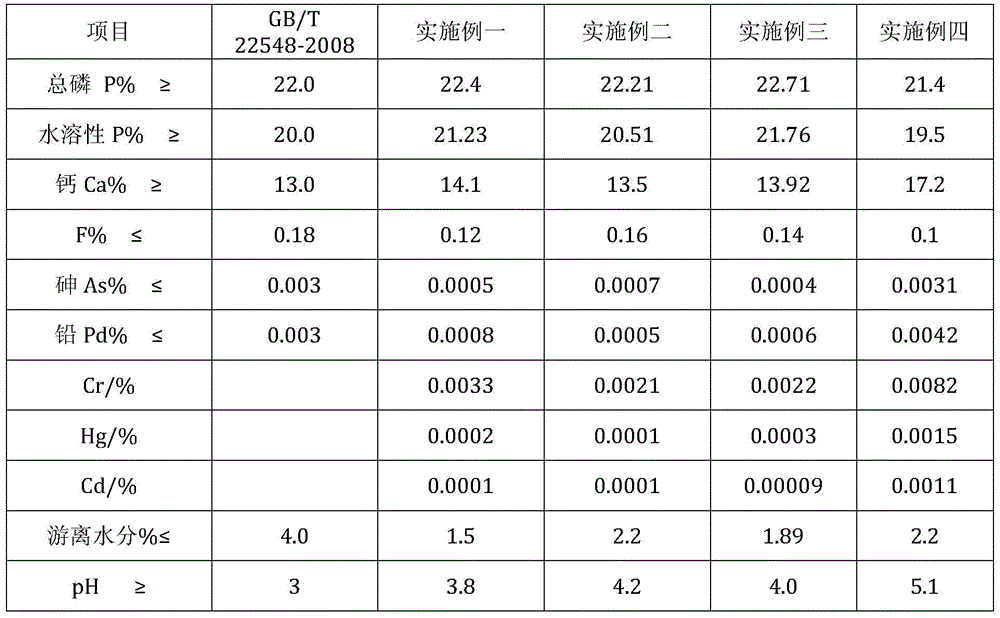

Process of producing feed-grade calcium dihydrogen phosphate through phosphoric acid circulation impurity removal method

The invention discloses a process of producing feed-grade calcium dihydrogen phosphate through a phosphoric acid circulation impurity removal method, wherein the method comprises following steps: (a) decomposing acid mine; (b) maintaining the temperature and performing sedimentation to obtain a slurry material; (c) feeding the slurry material to a crystallization trough, cooling the slurry material to 30-60 DEG C and performing solid-liquid separation to obtain a filtrate and a filter residue; (d) adding water to the filter residue for making material slurry of which the specific gravity is 1.30-1.60; (e) maintaining the temperature and performing sedimentation to obtain a material slurry; (f) feeding the material slurry in the step (e) to a dryer with high-temperature gas flow to dry the material slurry, and adding an alkaline substance to a dried product to obtain the feed-grade calcium dihydrogen phosphate product; and (g) mixing a filtrate in the step (c) with phosphoric acid by wet process, and removing impurities to obtain an acid liquid used for decomposing the acid mine in the step (a). The process is good in adaptability of phosphorus ore, can ensure the product in the step (f) and heavy metals to meet a standard completely, can reduce discharge load of phosphogypsum and is good in application prospect.

Owner:GUIZHOU CHANHEN CHEM CO LTD

Method for defluorinating fluorine-containing hydrochloric acid

InactiveCN106882768AAchieve recyclingReduce manufacturing costChlorine/hydrogen-chloride purificationBoron containingPotassium

The invention discloses a method for defluorination of fluorine-containing hydrochloric acid. A soluble inorganic boron-containing compound and a soluble inorganic potassium-containing compound are added as defluorination agents to fluorine-containing hydrochloric acid for reaction, and the obtained reaction solution is distilled to obtain defluorination hydrochloric acid products. The invention has the advantages of simple process, high operating flexibility, high defluorination efficiency, and environmental protection.

Owner:JUHUA GROUP TECH CENT

Production method of feed grade calcium phosphate acidity agent

ActiveCN101288440AThe material is dry and does not stickShort defluorination timeAnimal feeding stuffAccessory food factorsCalcium biphosphatePhosphorite

The invention discloses a production method for a feed-grade calcium phosphate acidity agent; the production method includes that: excessive phosphoric acid and ground phosphorite are added in a reactor for hybrid reaction to prepare calcium dihydrogen phosphate material containing fluorine and phosphoric acid, the material is added into a dryer for drying and defluorination to prepare the defluorinated calcium phosphate acidity agent containing free phosphoric acid. The production method has the main technical advantages of quick defluorination, extremely high efficiency, resource saving, extremely low cost, environmental-friendly property, energy saving and emission reduction; the technique inevitably brings about the revolution of feed calcium phosphate acidity agent industry.

Owner:GUIZHOU CHANHEN CHEM CO LTD

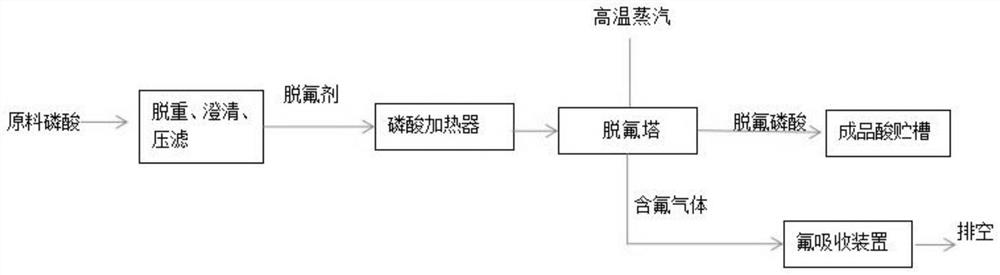

Method for catalytically improving wet-process phosphoric acid steam stripping defluorination efficiency

ActiveCN110817820ALow impurity contentImprove qualityPhosphorus compoundsCalcium biphosphateO-Phosphoric Acid

The invention discloses a method for catalytically improving wet-process phosphoric acid steam stripping defluorination efficiency, and relates to the technical field of wet-process phosphoric acid defluorination processes. By carrying out arsenic removal and heavy metal removal purification procedures on raw material phosphoric acid, clear purified concentrated phosphoric acid with low impurity content can be obtained; after a defluorination catalyst is added into the purified concentrated phosphoric acid, the defluorination catalyst and a defluorination agent are mixed and heated, and then steam stripping defluorination is performed, so that the defluorination resistance can be effectively reduced, the defluorination efficiency is improved, the consumption of the defluorination agent, steam and electricity in the defluorination process is reduced, and the defluorination cost is reduced; in the defluorination process, a steam stripping defluorination process is adopted, and an indirect steam heating mode is adopted; the defluorinated phosphoric acid production efficiency is high, the yield is high, the consumption is low, the phosphoric acid quality is good, the impurity content is low, the phosphorus-fluorine ratio (P2O5 / F) can reach 285 or above, and the defluorinated phosphoric acid can be directly used for producing feed-grade calcium phosphate.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

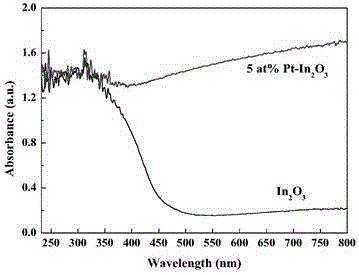

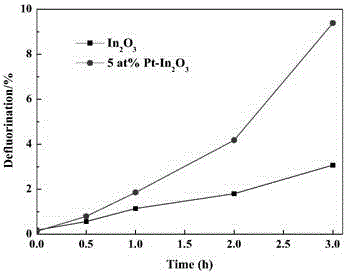

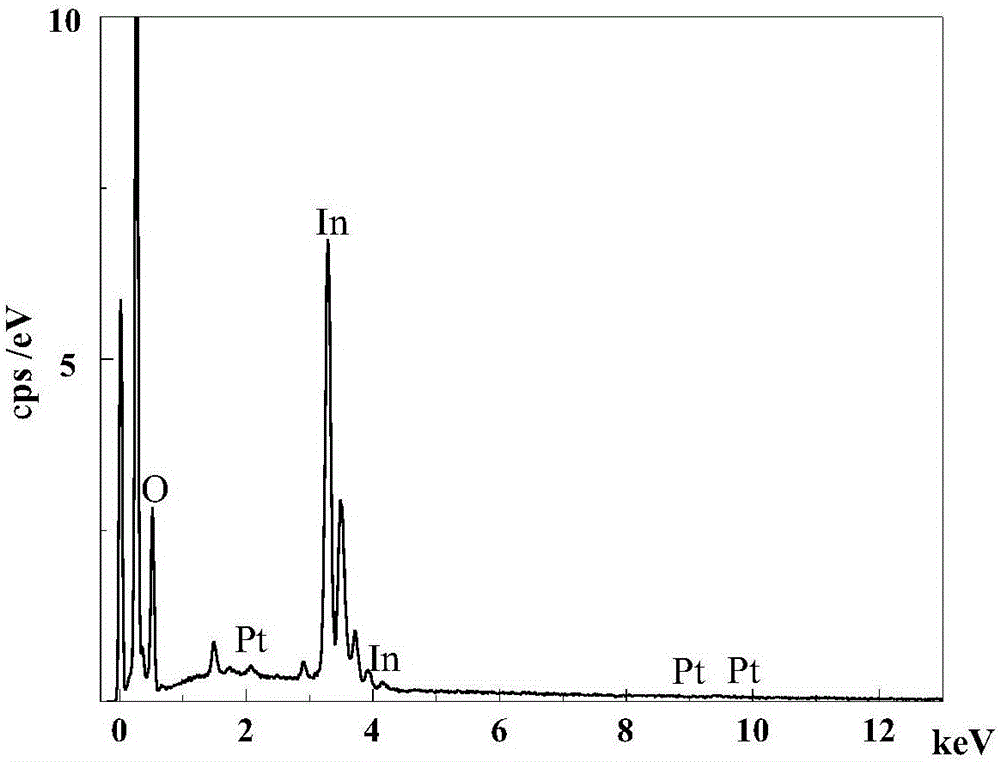

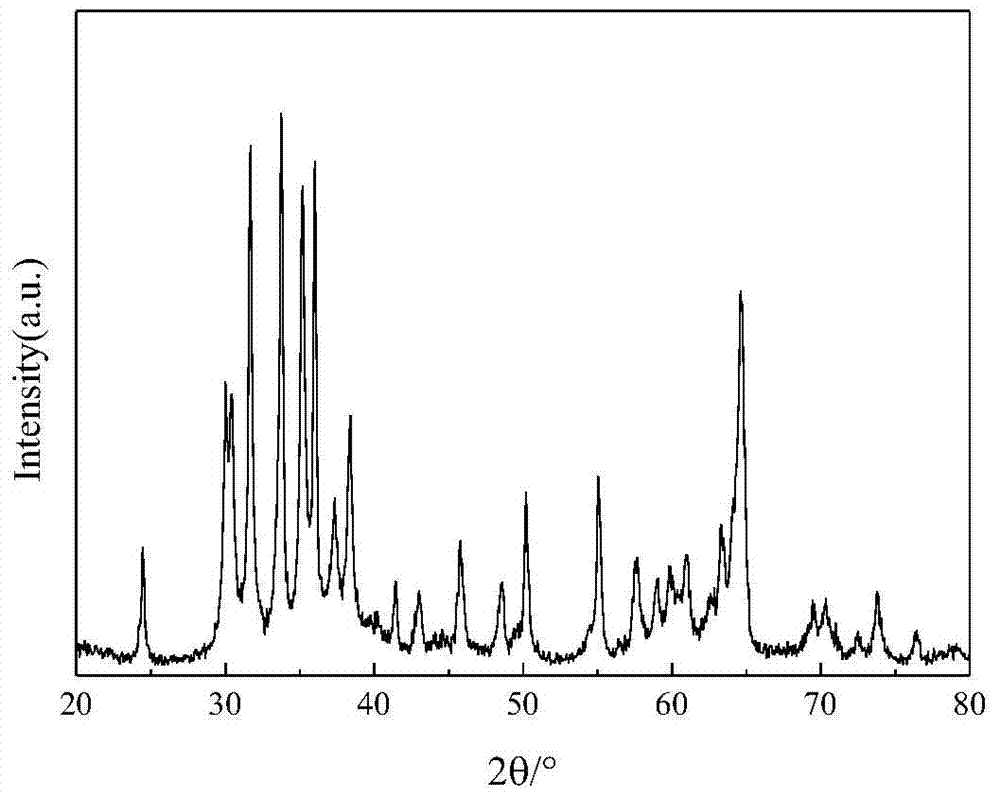

Method for degrading PFOA (perfluorooctanoic acid) in water by using Pt-doped In2O3 photocatalysis

ActiveCN106219666AInhibitory complexHigh defluorination efficiencyWater/sewage treatment by irradiationWater treatment compoundsPerfluorooctanoic acidElectron storage

The invention belongs to the technical field of water treatment, and particularly relates to a method for degrading PFOA (perfluorooctanoic acid) in water by using Pt-doped In2O3 photocatalysis. The method comprises the following steps: preparing a Pt-doped In2O3 catalyst by a photoreduction process, and degrading the PFOA by using Pt-doped In2O3 photocatalysis. The doped Pt can be used as an electron storage spot to effectively transfer photogenerated electrons generated on In2O3, and can prevent the photogenerated electrons and holes from compounding, thereby enhancing the PFOA defluorination efficiency; and the photocatalytic defluorination efficiency of the Pt-doped In2O3 for PFOA is 2-4 times of that of the In2O3. The Pt is doped in the In2O3 to greatly enhance the optical absorptivity of the In2O3, so that the In2O3 has high absorptivity for 350nm+ light, thereby being beneficial to implementing utilization of the clean energy-sunlight energy.

Owner:GUANGXI UNIV

Method for reducing fluoride in diluted phosphoric acid by wet process

InactiveCN101525129AReduce fluorine contentReduce corrosionPhosphorus compoundsO-Phosphoric AcidPhosphogypsum

A method for reducing fluoride in diluted phosphoric acid by wet process is provided. In the method, sodium sulfate is taken as defluoridator, phosphoric acid is added during production of phosphoric acid by wet process for reaction to extract sections, reaction time between sodium sulfate defluoridator and hydrofluosilicic acid in slurry is maintained between 0.2-6 hours; fluorine in diluted acid is precipitated in the form of fluoride or fluorosilicate to enter phosphoric acid slurry solid phase; then, when being filtered, phosphogypsum enters phosphoric acid slurry solid phase to be separated and removed, thus lowering fluorine content in diluted phosphoric acid. Compared with the traditional defluorination method, the method of the invention has the following advantages: 1. defluorination efficiency is improved by more than 50%; 2. energy comsumption is low or process flow is short, production cost is lowered by more than 10% compared with the production cost of defluorinating phosphoric acid; 3. corrosion of fluorine on pipelines of the devices are reduced by about 5-15%, operating ratio of the devices is improved by about 1%; 4. the produced phosphate fertilizer products can meet the growth requirements of high-end crops; 5. the defluorination method is simple, convenient and easy to operate and control; 6. the investment is small. The method of the invention is applicable to factories producing phosphoric acid by wet process.

Owner:WENGFU (GRP) CO LTD

A method for photocatalytic degradation of perfluorooctanoic acid in water by noble metal doped gallium oxide

ActiveCN105060389BInhibitory complexFacilitate the reduction reactionWater/sewage treatment by irradiationWater contaminantsOctanoic AcidsPerfluorooctanoic acid

The invention belongs to the technical field of water treatment, and specifically relates to a method for photocatalytically degrading perfluorooctanoic acid in water doped with noble metal gallium oxide, comprising the following steps: preparing a noble metal doped gallium oxide catalyst and photocatalytically degrading perfluorooctanoic acid by using noble metal doped gallium oxide. Specifically, the noble metal salt solution is added to the gallium oxide suspension and mixed evenly, and then the reducing salt solution is added dropwise to reduce the metal particles on the gallium oxide surface to prepare a noble metal-doped gallium oxide photocatalyst, and then use the photocatalyst in the Degrade perfluorooctanoic acid under ultraviolet light, so as to achieve the purpose of removing perfluorooctanoic acid in water. The method of the invention has the advantages of simple photocatalyst preparation method, degrading perfluorooctanoic acid under normal temperature and pressure conditions, no need for complex devices and high degradation efficiency.

Owner:GUANGXI UNIV

Defluorination method of acidic aqueous solution containing hydrofluoric acid

InactiveCN106927423AEfficient cycleSimple processChlorine/hydrogen-chloride purificationHydrofluoric acidReaction temperature

The invention discloses a defluorination method of an acidic aqueous solution containing hydrofluoric acid. The method comprises the following steps: (a) facilitating the reaction of the acidic aqueous solution containing the hydrofluoric acid and edittrialkyl chlorosilane or a mixture of edittrialkyl chlorosilane and hexaethyldisiloxane, wherein the reaction temperature is 10 to 80 DEG C, the reaction time is 5 to 100 min, separating an obtained reaction solution, wherein an upper layer is an organic silicon mixture, and a lower layer is a defluorinated acidic aqueous solution; and (b) mixing the organic silicon mixture obtained in step (a) and an alkaline solution, performing regenerative reaction, separating an obtained regenerated reaction solution, wherein the lower layer is an alkaline solution containing fluoride salt, and the upper layer is hexaethyldisiloxane. The method has the advantages of simple process, high operation flexibility, high defluorination efficiency, environmental friendliness and environmental protection.

Owner:JUHUA GROUP TECH CENT

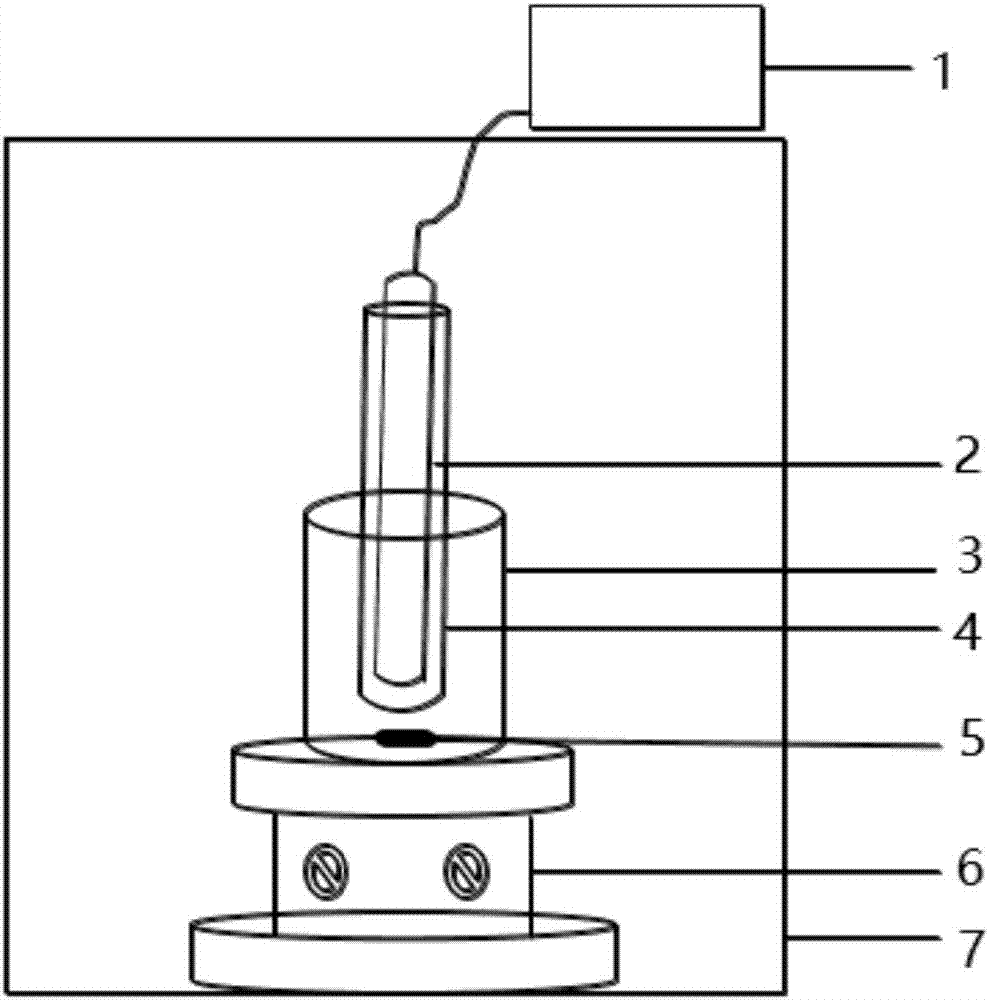

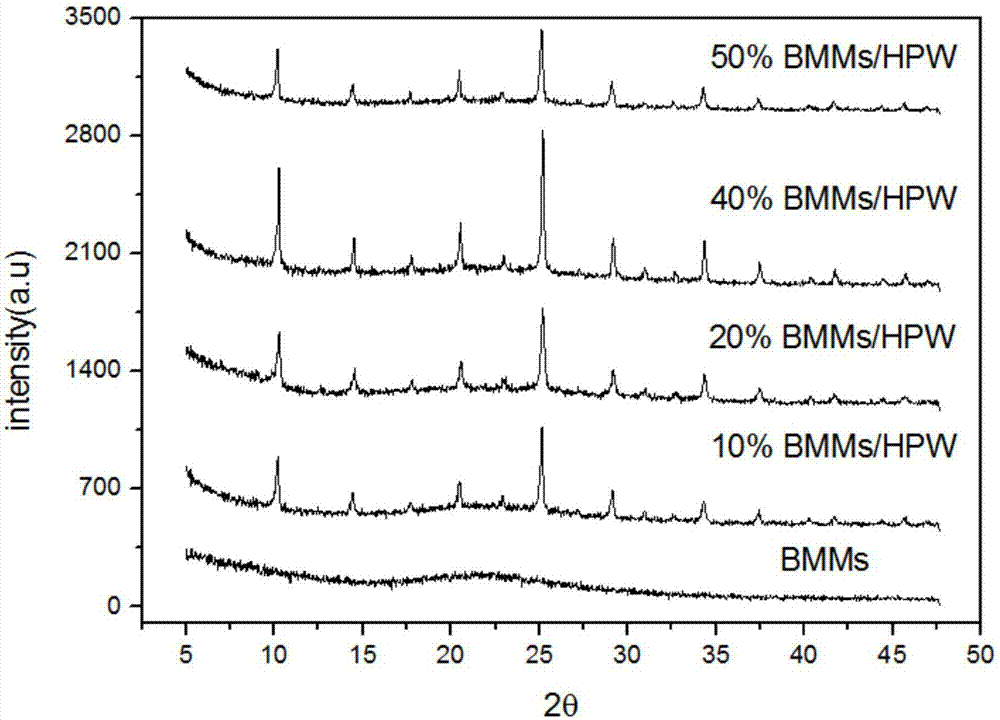

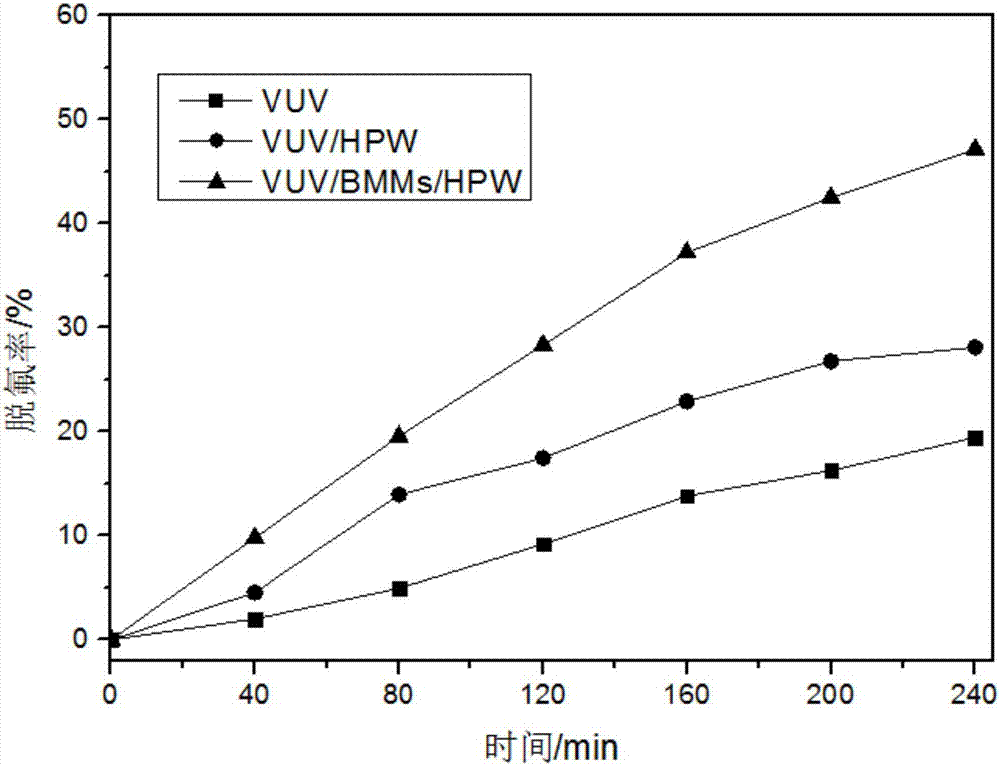

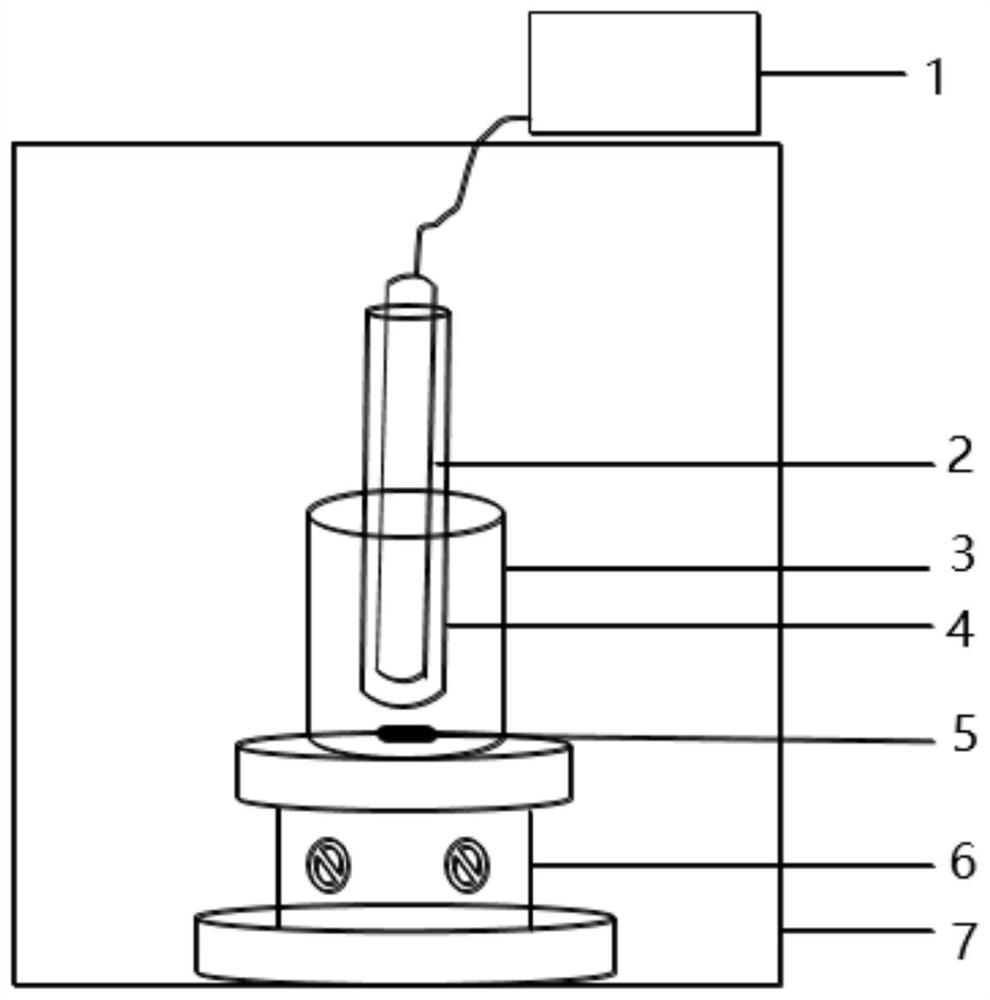

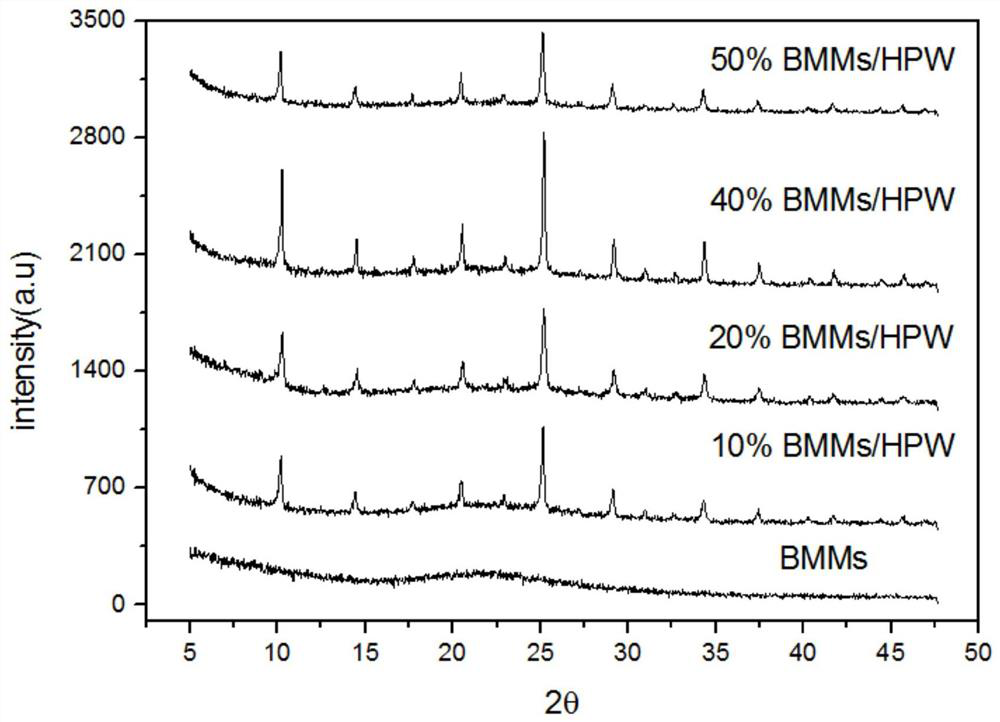

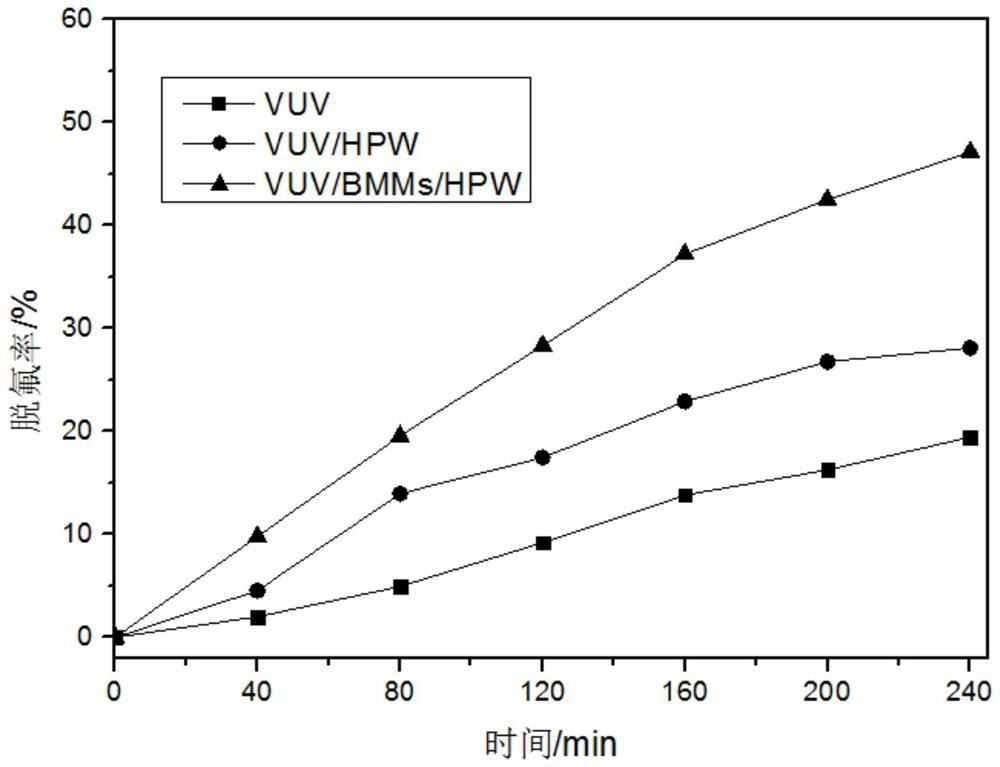

Method of photocatalytically degrading perfluoro-compounds

ActiveCN107416943AHigh defluorination efficiencyLarge specific surface areaWater/sewage treatment by irradiationWater treatment compoundsActive componentPhotocatalytic degradation

The invention belongs to the field of degradation of persistent pollutants and discloses a method of photocatalytically degrading perfluoro-compounds. The method includes the steps of: a) preparing a double-model mesoporous SiO2 material BMMs, and with phosphotungstic acid as an active component, preparing a HPW / BMMs catalyst through impregnation; b) adding the HPW / BMMs catalyst to a perfluoro-compound solution, and at normal temperature and under normal pressure, irradiating the solution under an ultraviolet lamp to achieve degradation and defluorination to the perfluoro-compounds. The method is simple and has gentle conditions, increases the defluorination rate on the perfluoro-compounds, and achieves effective degradation of the perfluoro-compounds.

Owner:SOUTH CHINA UNIV OF TECH

A kind of non-phosphate precipitation wet phosphoric acid purification method

ActiveCN105366654BWide variety of sourcesSimple reaction conditionsPhosphorus compoundsChemical industryO-Phosphoric Acid

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

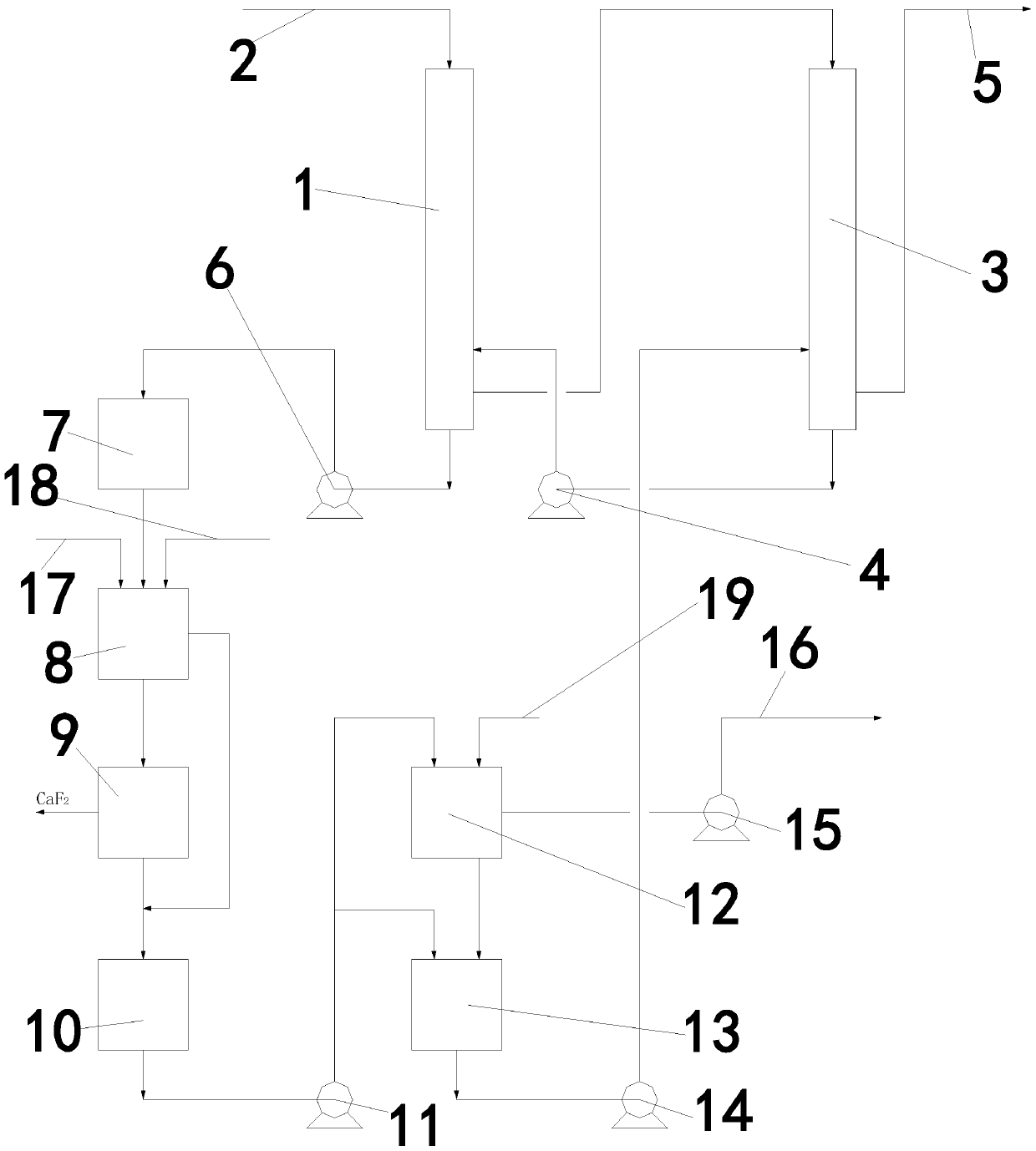

Pyrite-to-sulfuric acid flue gas defluorination equipment and pyrite-to-sulfuric acid flue gas defluorination process method

InactiveCN111036038AImprove processing efficiencyCompact structureGas treatmentDispersed particle separationFlue gasPyrite

The invention relates to pyrite-to-sulfuric acid flue gas defluorination equipment, which comprises a reaction furnace, an efficient washing tower and a middle washing tower, wherein the efficient washing tower comprises a first defluorination material inlet, and the middle washing tower comprises a second defluorination material inlet formed in the side wall. According to the invention, a two-stage washing tower with defluorination gradient is arranged to treat so as to improve the defluorination efficiency, and different defluorination materials can be added to achieve efficient defluorination treatment; the equipment is small in occupied area and high in defluorination efficiency, and is suitable for transformation and upgrading of old factories; the process method of the pyrite-to-sulfuric acid flue gas defluorination equipment comprises the following steps: S1, introducing furnace gas into the efficient washing tower; S2, adding a first defluorination material into the efficient washing tower; S3, adding a second defluorination material into the middle washing tower; and S4, discharging the treated furnace gas; and the process method has the advantages of high defluorination efficiency and convenience in raw material obtaining of pyrite-to-sulfuric acid preparation plants, and is suitable for transformation and upgrading of old plants.

Owner:洛阳丰瑞氟业有限公司

Governing method for discharging fluorine-containing gas amorphously in aluminum electrolysis production process

ActiveCN107983128ALow fluorine concentrationTroubleshoot clogged nozzlesGas treatmentDispersed particle separationElectrolysisAluminum electrolysis

The invention relates to a governing method for discharging fluorine-containing gas amorphously in an aluminum electrolysis production process. The method comprises the following steps: (1) arrangingmultiple layers of nozzles which are arranged in a staggered manner at a discharge skylight of an aluminum electrolysis plant and spraying an alkaline sodium metaaluminate solution through the nozzles, wherein the alkaline sodium metaaluminate solution absorbs an absorption liquid containing cryolite after the fluorine-containing is discharged amorphously, and gaseous hydrogen fluoride and alkaline sodium metaaluminate react to generate cryolite; (2) collecting and filtering the absorption liquid containing cryolite, wherein the solid phase is cryolite; and adding sodium metaaluminate into thefiltrate for circular use; and (3) demisting the washed gas and discharging the gas into atmosphere. The method provided by the invention has the advantages of being simple in process, convenient tooperate, small in energy consumption, good in pollutant removal effect and the like.

Owner:NORTHEASTERN UNIV

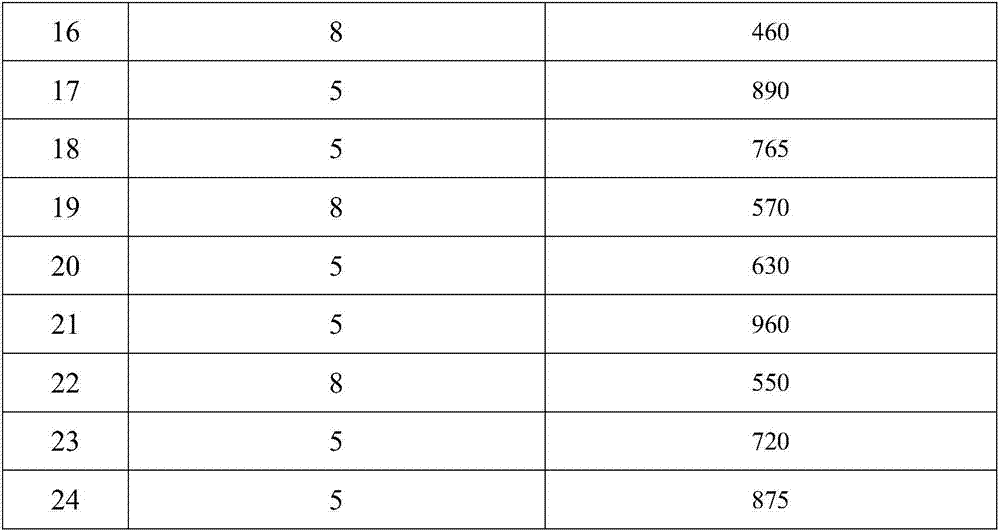

A method for catalytically improving the defluorination efficiency of wet-process phosphoric acid stripping

ActiveCN110817820BLow impurity contentImprove qualityPhosphorus compoundsCalcium biphosphateO-Phosphoric Acid

The invention discloses a method for catalytically improving wet-process phosphoric acid steam stripping defluorination efficiency, and relates to the technical field of wet-process phosphoric acid defluorination processes. By carrying out arsenic removal and heavy metal removal purification procedures on raw material phosphoric acid, clear purified concentrated phosphoric acid with low impurity content can be obtained; after a defluorination catalyst is added into the purified concentrated phosphoric acid, the defluorination catalyst and a defluorination agent are mixed and heated, and then steam stripping defluorination is performed, so that the defluorination resistance can be effectively reduced, the defluorination efficiency is improved, the consumption of the defluorination agent, steam and electricity in the defluorination process is reduced, and the defluorination cost is reduced; in the defluorination process, a steam stripping defluorination process is adopted, and an indirect steam heating mode is adopted; the defluorinated phosphoric acid production efficiency is high, the yield is high, the consumption is low, the phosphoric acid quality is good, the impurity content is low, the phosphorus-fluorine ratio (P2O5 / F) can reach 285 or above, and the defluorinated phosphoric acid can be directly used for producing feed-grade calcium phosphate.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

A load-type defluorination agent for removing hydrogen fluoride in hydrogen chloride gas and its preparation method

ActiveCN104128162BHigh defluorination efficiencyGreat operating flexibilityChlorine/hydrogen-chloride purificationOther chemical processesHydrogen fluorideMass ratio

The invention discloses a load-type fluorine remover used for removing hydrogen fluoride in hydrogen chloride gas, which is composed of a porous carrier and a fluorine removal active ingredient loaded on the porous carrier, the fluorine removal active ingredient can be existed on inner part and external surface of the tunnel of the porous carrier in a thin layer mode with particles of 0.1nm-5mum, and the mass ratio of the fluorine removal active ingredient to the porous carrier is 0.0005-3: 1. The invention also provides a preparation method of the load-type fluorine remover. The preparation method thereof has the advantage of simple process, and the prepared load-type fluorine remover has the advantages of high utilization rate, good fluorine removal effect and green environmental protection.

Owner:ZHEJIANG JUHUA CO LTD

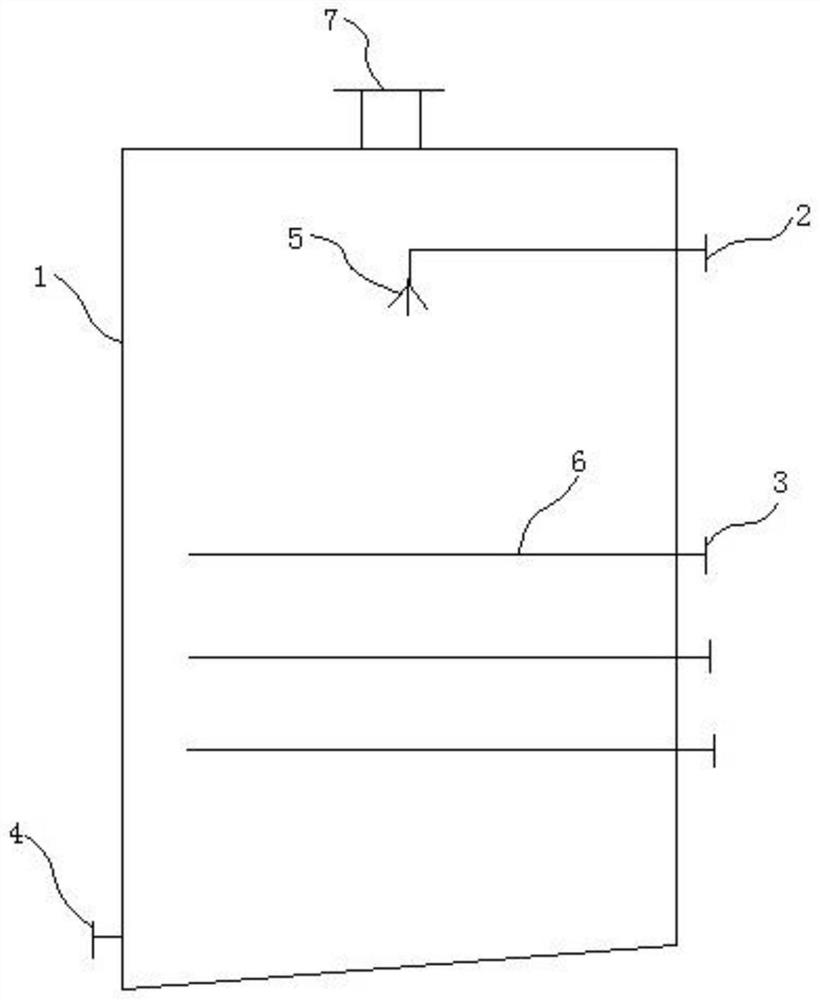

A high-temperature stripping defluorination method and device for wet-process phosphoric acid

ActiveCN112174104BIncrease productionImprove qualityChemical industryPhosphorus compoundsCalcium biphosphateO-Phosphoric Acid

The invention discloses a high-temperature stripping defluorination method of wet-process phosphoric acid and a device thereof, and relates to the technical field of wet-process phosphoric acid defluorination. In the method, the raw material phosphoric acid is firstly treated to remove heavy metals, and then the solid impurities in the phosphoric acid are removed by clarification and pressure filtration to obtain clarified concentrated phosphoric acid with low solid content; Heat to 70-90°C, pump phosphoric acid into the defluorination tower for stripping and defluorination, keep the phosphoric acid in the liquid storage tank at the lower part of the defluorination tower in a boiling state, and recover the fluorine-containing gas by washing with water to obtain the phosphorus-fluorine ratio P 2 o 5 Defluorophosphoric acid with low fluorine content and / F above 380. In the boiling state of phosphoric acid, the escape efficiency of fluorine-containing gas in phosphoric acid can be improved, the fluorine content in acid can be effectively reduced, and the defluorination efficiency and the output of defluorinated phosphoric acid can be improved. The defluorinated phosphoric acid produced by the method has good quality and high yield, and can not only be directly used to produce feed-grade calcium phosphate, but also can be applied to fields requiring higher phosphoric acid quality.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

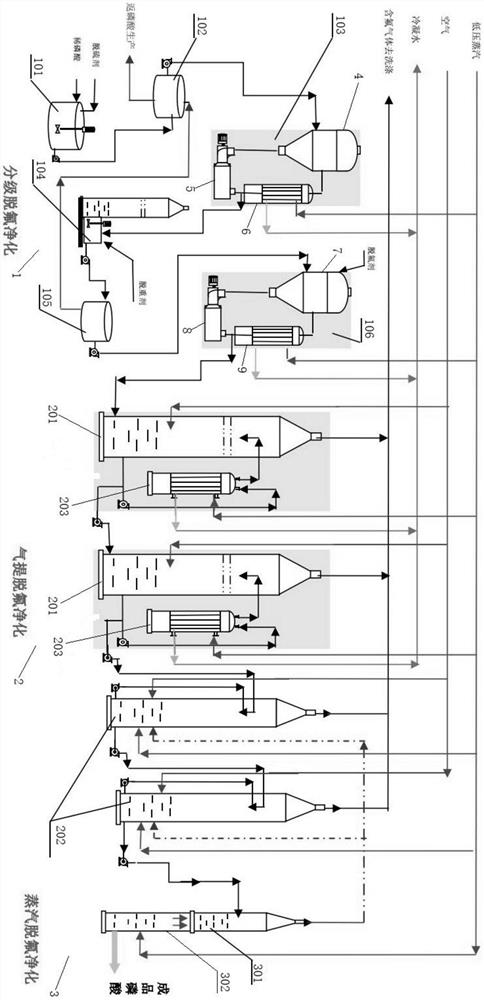

A system for preparing feed-grade phosphoric acid by wet-process phosphoric acid and its preparation method

ActiveCN111704118BEasy to settle and separateHigh yieldPhosphorus compoundsO-Phosphoric AcidSulfate radicals

The invention discloses a system and a preparation method for preparing feed-grade phosphoric acid from wet-process phosphoric acid, and relates to the technical field of phosphoric acid production. The preparation method is composed of processes such as wet-process phosphoric acid desulfate radical removal, heavy metal removal, graded concentration defluorination, air stripping defluorination, steam defluorination and the like. Using wet-process phosphoric acid as raw material to remove sulfate and heavy metal ions in phosphoric acid under different phosphoric acid concentration conditions, the feed grade is completed by using steps such as fractional concentration defluorination section, multi-stage series gas defluorination section and steam defluorination section. Purify phosphoric acid to obtain high-quality feed-grade phosphoric acid. The method for preparing feed-grade phosphoric acid by wet-process phosphoric acid does not require phosphoric acid filtration or pressure filtration, and no slag phosphoric acid and solid waste are generated during the process, with high phosphorus yield, high defluorination efficiency, good recovery of fluorine resources, and P in the product phosphoric acid. 2 o 5 The / F can reach more than 300, the process continuity is good, the device capacity is large, and it also has the characteristics of low comprehensive energy consumption and excellent investment. The maximum can reach 300,000 tons P 2 o 5 / year.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

Process for producing feed grade calcium dihydrogen phosphate by phosphoric acid recycling method

The invention discloses a process of producing feed-grade calcium dihydrogen phosphate through a phosphoric acid circulation impurity removal method, wherein the method comprises following steps: (a) decomposing acid mine; (b) maintaining the temperature and performing sedimentation to obtain a slurry material; (c) feeding the slurry material to a crystallization trough, cooling the slurry material to 30-60 DEG C and performing solid-liquid separation to obtain a filtrate and a filter residue; (d) adding water to the filter residue for making material slurry of which the specific gravity is 1.30-1.60; (e) maintaining the temperature and performing sedimentation to obtain a material slurry; (f) feeding the material slurry in the step (e) to a dryer with high-temperature gas flow to dry the material slurry, and adding an alkaline substance to a dried product to obtain the feed-grade calcium dihydrogen phosphate product; and (g) mixing a filtrate in the step (c) with phosphoric acid by wet process, and removing impurities to obtain an acid liquid used for decomposing the acid mine in the step (a). The process is good in adaptability of phosphorus ore, can ensure the product in the step (f) and heavy metals to meet a standard completely, can reduce discharge load of phosphogypsum and is good in application prospect.

Owner:GUIZHOU CHANHEN CHEM CO LTD

A method for photocatalytic degradation of perfluorinated compounds

ActiveCN107416943BHigh defluorination efficiencyLarge specific surface areaWater/sewage treatment by irradiationWater treatment compoundsPhoto catalyticPtru catalyst

The invention belongs to the field of degradation of persistent pollutants and discloses a method of photocatalytically degrading perfluoro-compounds. The method includes the steps of: a) preparing a double-model mesoporous SiO2 material BMMs, and with phosphotungstic acid as an active component, preparing a HPW / BMMs catalyst through impregnation; b) adding the HPW / BMMs catalyst to a perfluoro-compound solution, and at normal temperature and under normal pressure, irradiating the solution under an ultraviolet lamp to achieve degradation and defluorination to the perfluoro-compounds. The method is simple and has gentle conditions, increases the defluorination rate on the perfluoro-compounds, and achieves effective degradation of the perfluoro-compounds.

Owner:SOUTH CHINA UNIV OF TECH

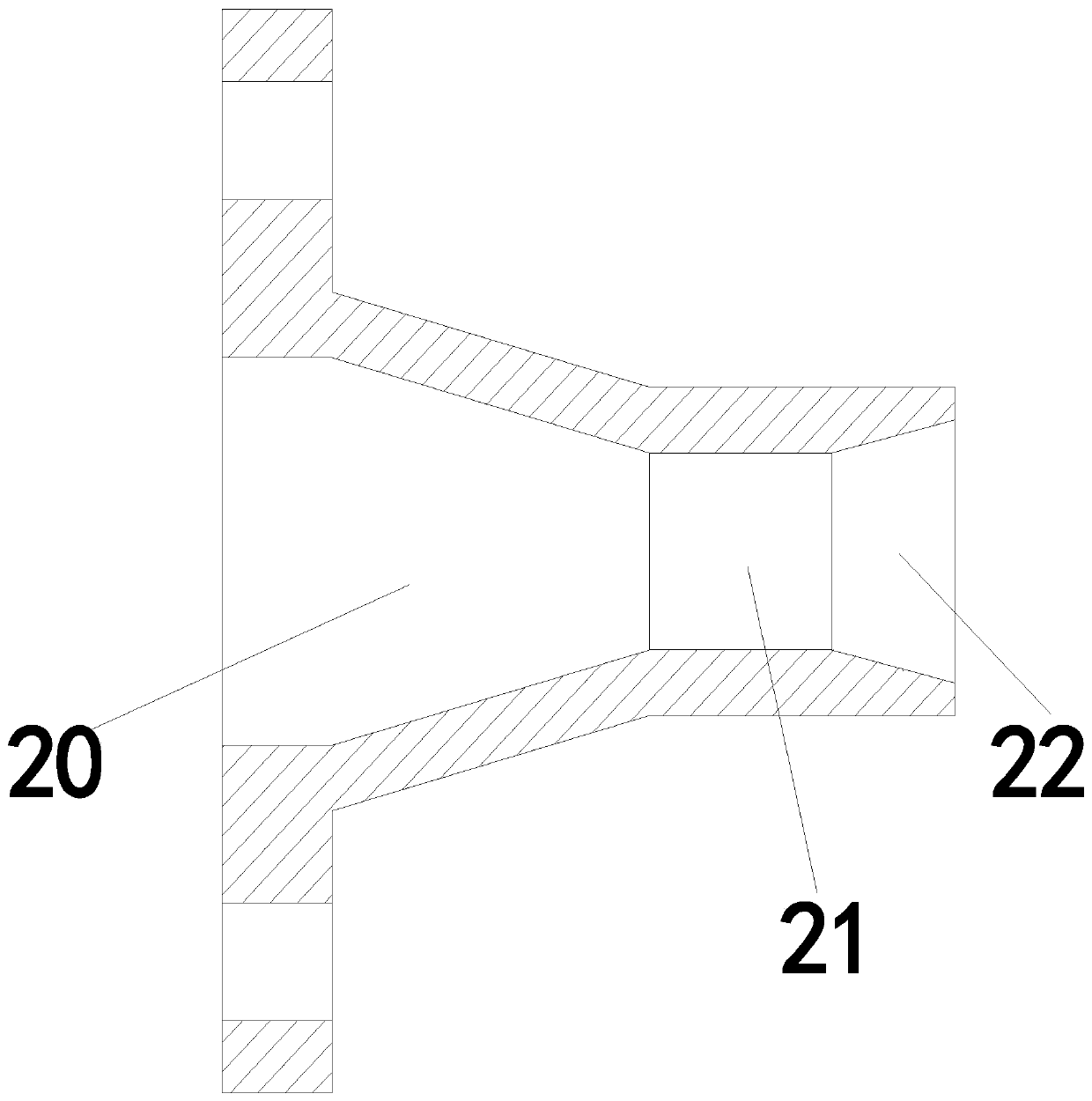

A device for removing hydrogen fluoride in tail gas by using dynamic wave and its realization method

ActiveCN105536474BSimple structureLow costGas treatmentDispersed particle separationEngineeringLiquid gas

The invention discloses a device for removing hydrogen fluoride from tail gas by virtue of dynamic waves. The device comprises a primary dynamic power absorption tower, wherein the primary dynamic wave absorption tower is connected with a secondary dynamic power absorption tower; a first water pump is arranged between the primary and secondary dynamic wave absorption towers; the primary dynamic power absorption tower is connected with a settling tank through a second water pump; the settling tank is connected with a filter pressing and washing kettle which is connected with a centrifuge and a mother liquor tank respectively; the centrifuge is connected with the mother liquor tank; the mother liquor tank is connected with a neutralizing tank and a circulating absorption liquid tank through a third water pump respectively; the neutralizing tank is connected with the circulating absorption liquid tank which is connected with the secondary dynamic wave absorption tower through a fourth water pump; the neutralizing tank is connected with a de-condensed calcium chloride pipe through a fifth water pump. The invention further discloses an implementation method for the device for removing the hydrogen fluoride from the tail gas by virtue of the dynamic waves. The device has the characteristics of simple structure, low construction cost, low production cost, high defluorination efficiency, low liquid-gas ratio, convenience for overhauling and the like.

Owner:ZHEJIANG AVILIVE CHEM CO LTD +1

A treatment method for unorganized emission of fluorine-containing gas during aluminum electrolysis production process

ActiveCN107983128BLow fluorine concentrationTroubleshoot clogged nozzlesGas treatmentDispersed particle separationHydrogen fluorideAluminium electrolysis

A method for controlling the unorganized emission of fluorine-containing gas during the aluminum electrolysis production process, which is carried out according to the following steps: (1) Set up multi-layer staggered nozzles at the emission skylight of the aluminum electrolysis plant, and spray alkaline sodium metaaluminate through the nozzles Solution, alkaline sodium metaaluminate solution absorbs unorganized emission of fluorine-containing gas to form an absorption liquid containing cryolite, gaseous hydrogen fluoride and alkaline sodium metaaluminate form cryolite; (2) After collecting the absorption liquid containing cryolite Filter, and the solid phase is cryolite; the filtrate is added to sodium metaaluminate for recycling; (3) the scrubbing gas is discharged into the atmosphere after defogging. The method of the invention has the advantages of simple process, convenient operation, low energy consumption, and good pollutant removal effect.

Owner:NORTHEASTERN UNIV LIAONING

Method for producing feed-grade calcium phosphate

ActiveCN100595136CReduce acidityIncrease cycle ratioPhosphorus compoundsCalcium biphosphatePhosphate

The invention discloses a forage level calcium phosphate production method, comprising that excess phosphoric acid and rock phosphate are added into a reactor to react mixedly; the calcium dihydrogenphosphate material containing fluorine and phosphoric acid; the material is added into a drier to be dried and defluorinated, and the forage level calcium phosphate is made. The forage level calcium phosphate production method has the advantages of fast defluorination, high efficiency, resource saving, low cost, friendly environment, energy saving and emission reducing, which brings the industrialrevolution of forge phosphate.

Owner:GUIZHOU CHANHEN CHEM CO LTD

A defluorination roasting device and process for lithium-containing minerals

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A roasting defluorination device and process

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com