A device for removing hydrogen fluoride in tail gas by using dynamic wave and its realization method

A realization method, dynamic wave technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of low absorption efficiency, difficult separation of sedimentation, nozzle clogging, etc., and achieve simple structure, less one-time investment, The effect of reducing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

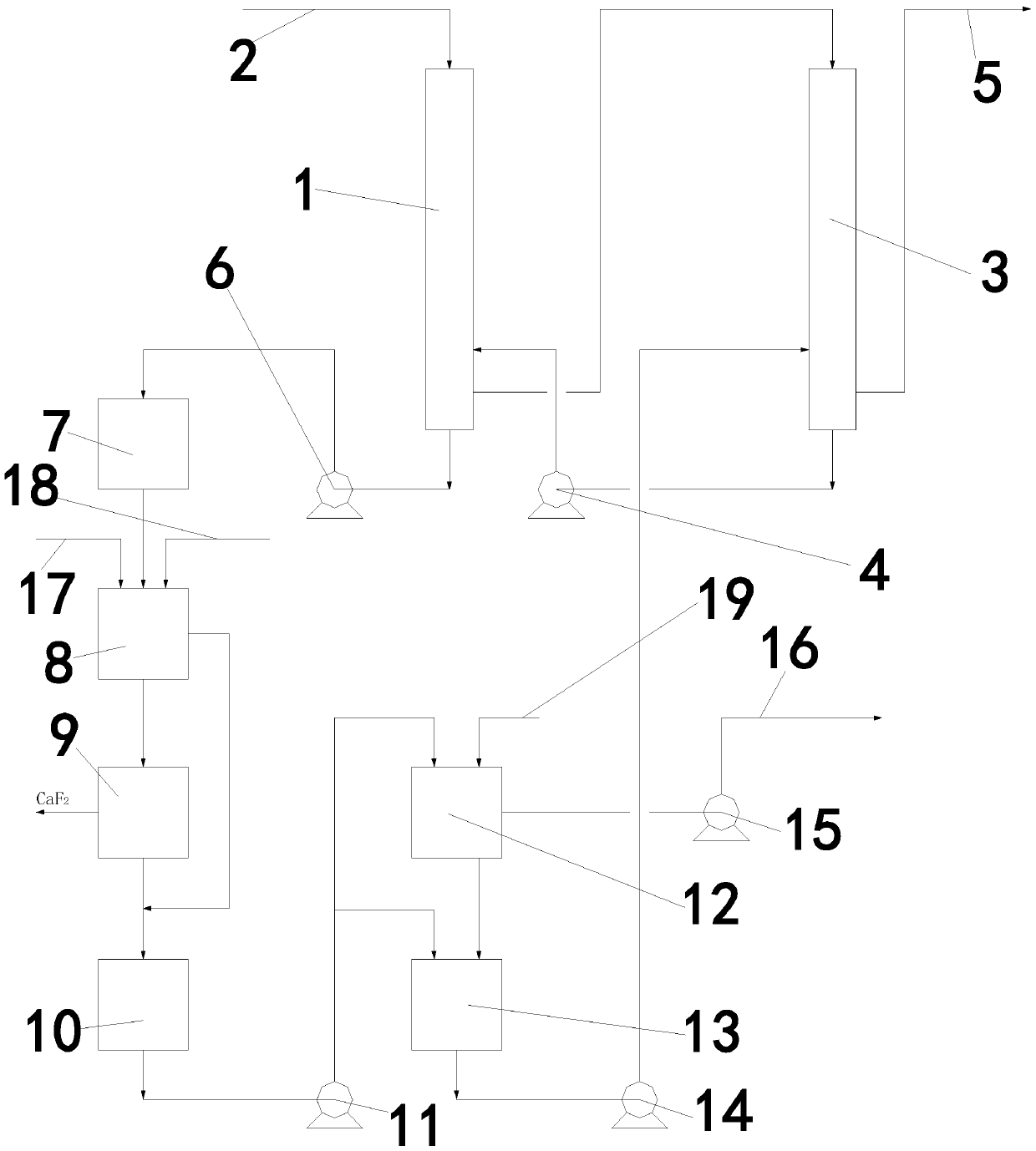

[0038] Such as figure 1 As shown, a device for removing hydrogen fluoride in tail gas by using dynamic wave, comprising a first-stage dynamic wave absorption tower 1, the top of the first-stage dynamic wave absorption tower 1 is provided with an exhaust gas inlet pipe 2, the first-stage dynamic wave absorption tower 1 and the second-stage The dynamic wave absorption tower 3 is connected, the first water pump 4 is provided between the primary dynamic wave absorption tower 1 and the secondary dynamic wave absorption tower 3, the exhaust gas output pipe 5 is arranged on the secondary dynamic wave absorption tower 3, and the primary dynamic wave absorption tower 3 is equipped with an exhaust gas output pipe 5. The absorption tower 1 is connected with the settling tank 7 by the second water pump 6, the settling tank 7 is connected with the filter press washing kettle 8, the filter press washing kettle 8 is connected with the centrifuge 9 and the mother liquor tank 10 respectively, a...

Embodiment 2

[0055] The differences between this embodiment and Embodiment 1 are: the fluorine-containing tail gas in this embodiment contains 5% hydrogen fluoride, the flow velocity of the absorption liquid nozzle is 30 m / s, the first-stage dynamic wave absorption tower 1 and the second-stage dynamic wave absorption The length of tower 3 is 8m; the height of the turbulence zone in the first-level dynamic wave absorption tower 1 and the second-level dynamic wave absorption tower 3 is 2.5m; the absorption liquid is a mixed solution of hydrogen chloride and calcium chloride, and the concentration of hydrogen chloride is 35%. The concentration of calcium chloride was 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com