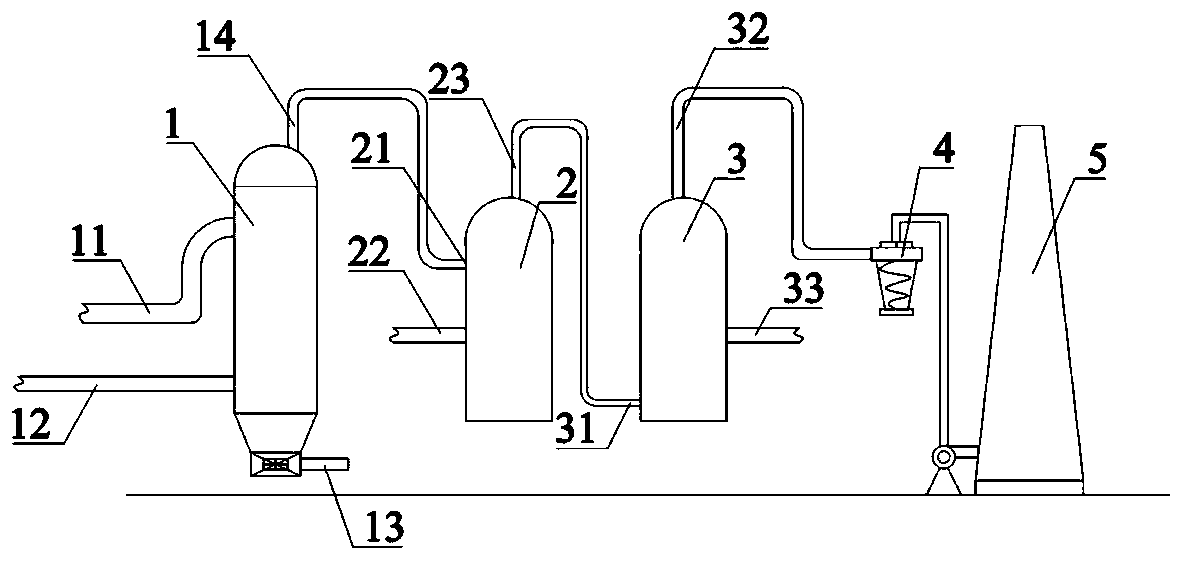

Pyrite-to-sulfuric acid flue gas defluorination equipment and pyrite-to-sulfuric acid flue gas defluorination process method

A process method and technology made from iron ore, applied in the field of flue gas defluorination, can solve the problems of small footprint fluoride removal equipment, reduced catalyst pulverization activity, collapse of ceramic rings in drying towers, etc. Convenience and compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

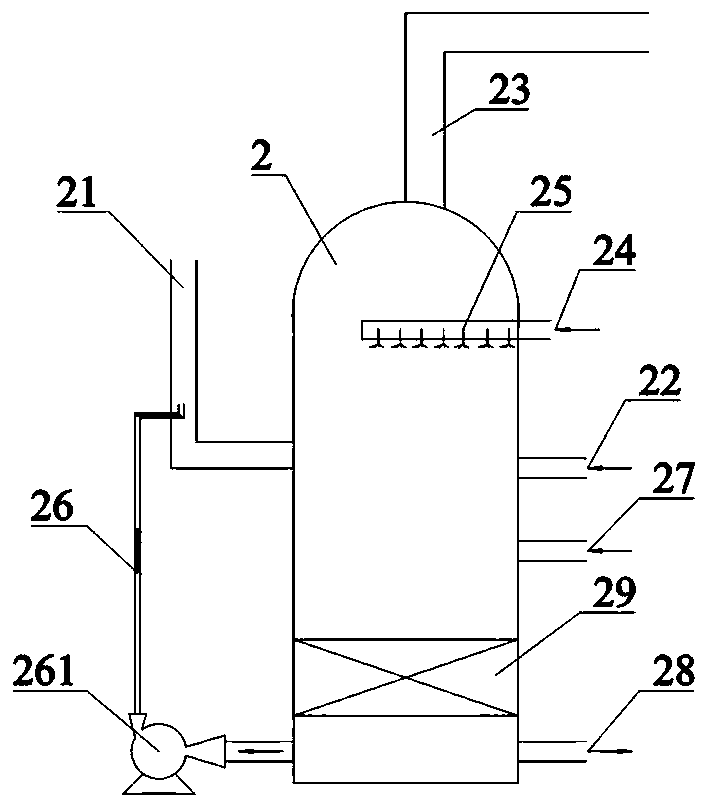

[0044] The furnace gas generated from the reaction furnace is guided into the high-efficiency scrubber. Add the first fluoride removal material in the high-efficiency scrubber, wherein the first fluoride removal material is a mixed agent of 6wt% polyferric sulfate solution, 80mg / L PAC coagulant, and 5mg / L PAM flocculant, and adjust the pH to 6.0, stirring for 1 min. Add the second fluoride removal material in the intermediate scrubber, wherein the second fluoride removal material is milk of lime, CaCl 2 , 80mg / L PAC coagulant, and 5mg / L PAM flocculant, adjust the pH to 11.0, and let it stand for 20min. The furnace gas treated by the intermediate scrubber is discharged.

Embodiment 2

[0046] The furnace gas generated from the reaction furnace is guided into the high-efficiency scrubber. Add the first fluoride removal material in the high-efficiency scrubber, wherein the first fluoride removal material is a mixed agent of 9wt% polyferric sulfate solution, 80mg / L PAC coagulant, and 5mg / L PAM flocculant, and adjust the pH to 7.5, stirring for 2min. Add the second fluoride removal material in the intermediate scrubber, wherein the second fluoride removal material is milk of lime, CaCl 2 , 80mg / L PAC coagulant, and 5mg / L PAM flocculant, adjust the pH to 10.5, and let it stand for 25 minutes. The furnace gas treated by the intermediate scrubber is discharged.

Embodiment 3

[0048] The furnace gas generated from the reaction furnace is guided into the high-efficiency scrubber. Add the first fluorine removal material in the high-efficiency scrubber, wherein the first fluoride removal material is a mixed agent of 7wt% polyferric sulfate solution, 80mg / L PAC coagulant, and 5mg / L PAM flocculant, and adjust the pH to 7. Stir for 1.5 minutes. Add the second fluoride removal material in the intermediate scrubber, wherein the second fluoride removal material is milk of lime, CaCl 2 , 80mg / L PAC coagulant, and 5mg / L PAM flocculant, adjust the pH to 11, and let it stand for 20min. The furnace gas treated by the intermediate scrubber is discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com