Method for producing feed-grade calcium phosphate

A production method, the technology of calcium phosphate, which is applied to the high-temperature drying of the material through a spray dryer, can solve the problems of calcium ion loss, long defluorination time, and large energy consumption, so as to reduce production costs, short defluorination time, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

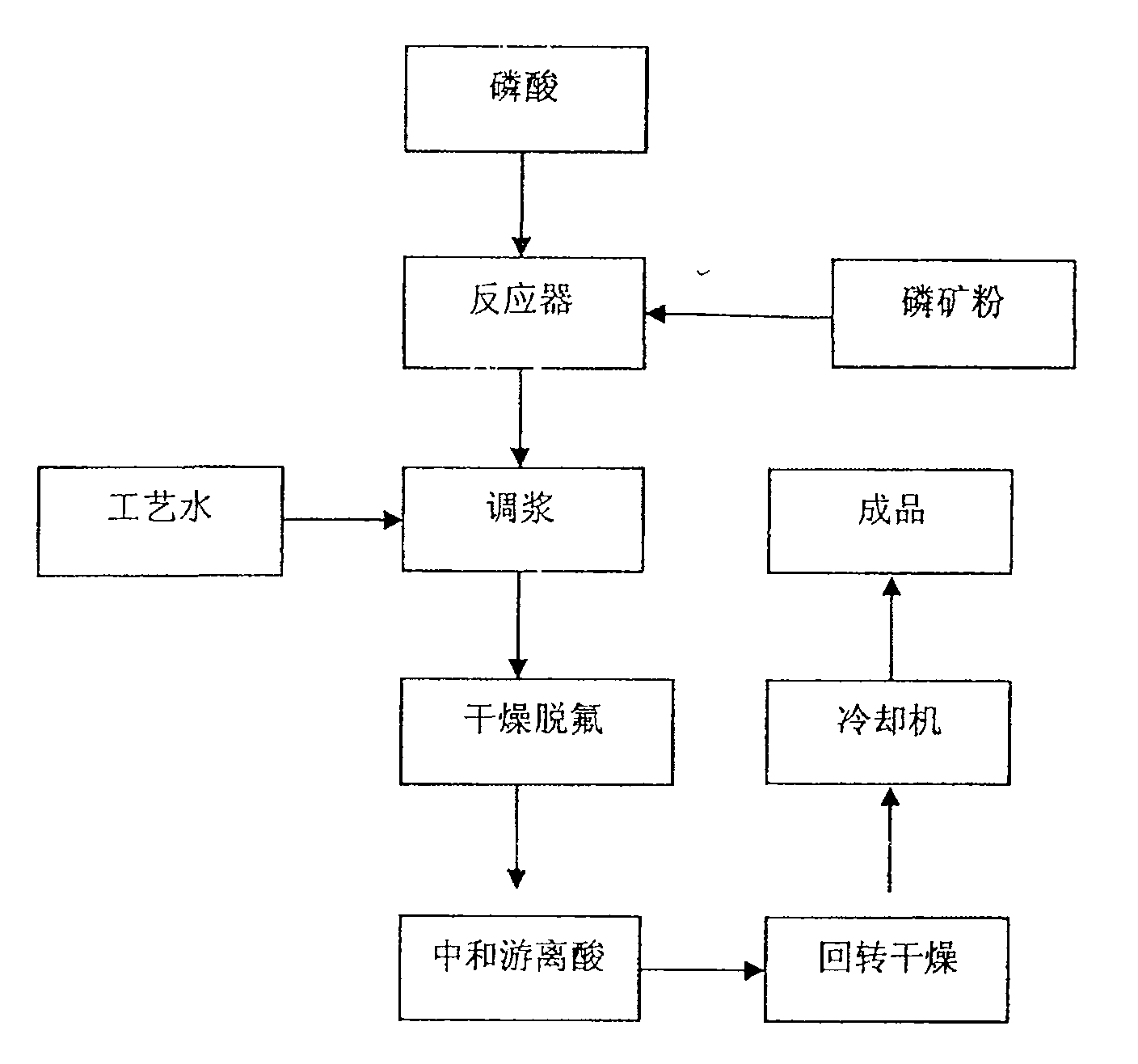

Image

Examples

Embodiment 1

[0041] Using Guizhou phosphate rock, its quality is: P 2 o 5 35.32%, CaO 48.74%, MgO 0.84% Fe 2 o 3 1.38%, Al 2 o 3 0.70%, F 2.48%, use a mill to grind -60 mesh to reach 90% fine powder, add phosphate rock powder and wet-process phosphoric acid with a phosphoric acid concentration of 69%, and add 40% excess wet-process phosphoric acid to the reactor at the same time, and react The materials are mixed and acidolyzed in the reactor. After the reaction time is 4 hours, water is added to the materials to make a thick slurry with a solid content of 58%, and then sent to the spray tower for atomization drying and defluorination. The temperature of the hot air entering the tower is 600°C , the temperature of the hot air coming out of the tower is 152°C, and the fluorine content of the acidic calcium phosphate after defluorination and drying is 0.14%. This material is sent to the mixer, and CaCO 3 and sprayed into water to neutralize free acid, and the material after neutral...

Embodiment 2

[0045] Using Guizhou phosphate rock, its quality is: P 2 o 5 33.32%, CaO 45.94%, MgO 0.94% Fe 2 o 3 1.68%, Al 2 o 3 0.30%, F 3.11%, use a mill to grind into -100 mesh to reach 82% fine powder, add phosphate rock powder and thermal phosphoric acid with a phosphoric acid concentration of 12%, add 30% excess thermal phosphoric acid to the reactor at the same time and mix Reaction, after 6 hours of reaction time, the prepared slurry is sent to the spray tower for atomization drying and defluorination. The temperature of the hot air entering the tower is 1000 ° C, and the temperature of the hot air exiting the tower is 298 ° C. The acidic calcium phosphate after defluorination and drying The fluorine content is 0.12%, and then this material is sent into the mixer, and the CaCO of the theoretical consumption of free phosphoric acid is added. 3 And spray into water to neutralize free acid, and the material of neutralizing free phosphoric acid is sent to the rotary drum dryer ...

Embodiment 3

[0049] Using Guizhou phosphorus concentrate, its quality is: P 2 o 5 36.92%, CaO 49.16%, MgO 0.60%, Fe 2 o 3 0.38%, Al 2 o 3 0.29%, F 3.62%, the fineness of the concentrate is -160 mesh and reaches 83%, the phosphoric acid powder and the phosphoric acid concentration of phosphoric acid are 52%, and the excess of 20% of the phosphoric acid is added to the reactor at the same time to mix and react. The time is 5 hours, and the slurry is sent to the spray tower for atomization drying and defluorination. The temperature of the hot air entering the tower is 155°C, and the temperature of the hot air exiting the tower is 72°C. The fluorine content of the acidic calcium phosphate after defluorination and drying is 0.17%. , and then send this material into the mixer, add CaO of the theoretical consumption of free phosphoric acid to the mixer and spray it into water to neutralize free phosphoric acid, and the material neutralized free phosphoric acid enters the rotary cylinder dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com