Method for removing and recycling hydrogen fluoride from hydrogen chloride gas

A technology of hydrogen chloride gas and hydrogen fluoride, applied in the direction of hydrogen fluoride, chlorine/hydrogen chloride, fluorine/hydrogen fluoride, etc., can solve a large amount of fluorine-containing waste water and fluorine-containing solid waste, fluorine resource transfer fee, heavy environmental protection pressure and other problems, and achieve low production cost , easy operation and high defluorination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

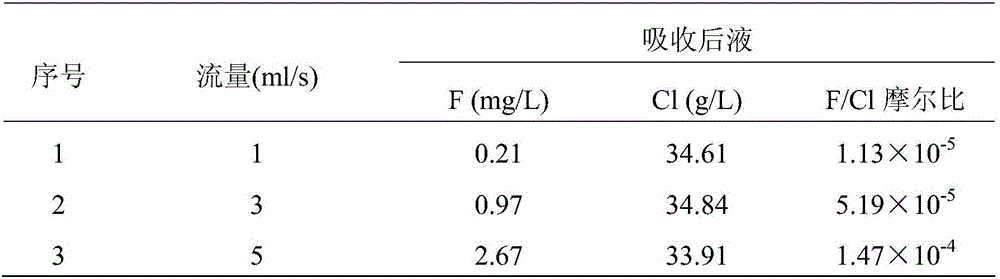

[0038] Use a 250ml plastic flask and a plastic burette to form a simple Kipp generator, and fill the flask with 100g of NaCl and NaF, and fill the Φ25×400 plastic ion exchange column with anhydrous chlorinated Calcium particles 250g, the inlet of the ion exchange column is connected with the gas outlet of the Kipp generator with a plastic hose, and then slowly add concentrated sulfuric acid through the burette to control the gas flow rate of the gas outlet of the Kipp generator to 1-5ml / s, start The gas generated by the general generator passes through the ion exchange column in the way of top in and bottom out, and the residual gas after the adsorption of the ion exchange column is absorbed by NaOH solution. The defluorination test results of different gas flow rates are as follows:

[0039]

Embodiment 2

[0041] Using 2-5mm calcium oxide particles as adsorbent, packing column (Φ500×3000), 6-stage series column, treating anhydrous hydrogen chloride by-product hydrogen chloride gas produced in the preparation process of chlorofluoroalkane in a chemical plant, of which the volume of HF The concentration is 1.5%, and the by-product hydrogen chloride gas passes through the adsorption column at room temperature at 10cm / s. When the volume concentration of HF at the outlet of the first-stage adsorption column reaches 3.5%, the adsorption column is switched, and a blank is connected in series after the sixth-stage adsorption column. Then connect the inlet of the by-product hydrogen chloride gas to the inlet of the second-stage adsorption column, close the gas inlet valve of the first-stage adsorption column, and use an inert gas to eject the residual by-product hydrogen chloride gas in the first-stage adsorption column. , close the gas outlet valve of the first-stage adsorption column, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com