A high-temperature stripping defluorination method and device for wet-process phosphoric acid

A wet-process phosphoric acid and defluorination technology, which is applied in chemical instruments and methods, phosphorus compounds, climate sustainability, etc., can solve the problems of high equipment requirements, low efficiency of defluorination process, low production capacity, etc., and achieve good quality and improved Effect of high defluorination efficiency and high yield

Active Publication Date: 2022-05-31

YUNNAN PHOSPHATE CHEM GROUP CORP

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] The purpose of the present invention is to provide a high-temperature stripping defluorination method of wet-process phosphoric acid and its device to solve the problems of low efficiency, low production capacity and high equipment requirements of the existing defluorination process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

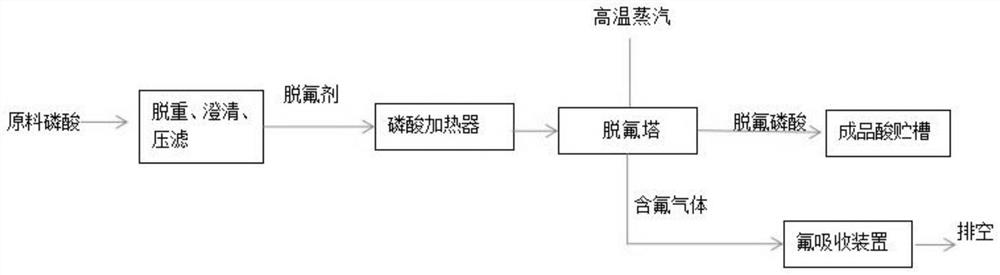

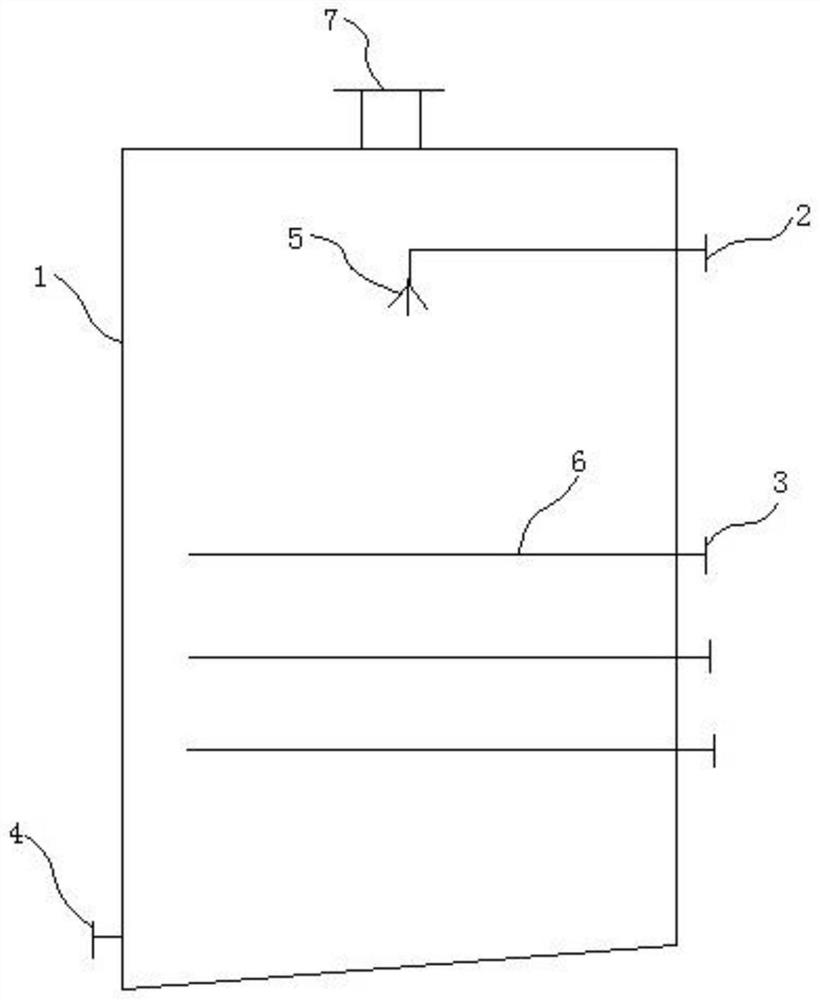

The invention discloses a high-temperature stripping defluorination method of wet-process phosphoric acid and a device thereof, and relates to the technical field of wet-process phosphoric acid defluorination. In the method, the raw material phosphoric acid is firstly treated to remove heavy metals, and then the solid impurities in the phosphoric acid are removed by clarification and pressure filtration to obtain clarified concentrated phosphoric acid with low solid content; Heat to 70-90°C, pump phosphoric acid into the defluorination tower for stripping and defluorination, keep the phosphoric acid in the liquid storage tank at the lower part of the defluorination tower in a boiling state, and recover the fluorine-containing gas by washing with water to obtain the phosphorus-fluorine ratio P 2 o 5 Defluorophosphoric acid with low fluorine content and / F above 380. In the boiling state of phosphoric acid, the escape efficiency of fluorine-containing gas in phosphoric acid can be improved, the fluorine content in acid can be effectively reduced, and the defluorination efficiency and the output of defluorinated phosphoric acid can be improved. The defluorinated phosphoric acid produced by the method has good quality and high yield, and can not only be directly used to produce feed-grade calcium phosphate, but also can be applied to fields requiring higher phosphoric acid quality.

Description

A kind of high temperature stripping defluorination method and device of wet phosphoric acid technical field The present invention relates to wet process phosphoric acid defluorination technical field, be specifically related to a kind of high temperature stripping defluorination method of wet process phosphoric acid and its device. Background technique Since the 1950s, all countries in the world have used wet-process phosphoric acid as a raw material to produce calcium phosphate as feed. Additives, feed-grade calcium phosphate salts are mainly calcium hydrogen phosphate DCP, calcium dihydrogen phosphate MCP, mono-dicalcium phosphate MDCP, among which Mainly calcium hydrogen phosphate. The source of phosphorus in the feed grade calcium hydrogen phosphate is mainly wet process phosphoric acid, and the key point of adopting wet process phosphoric acid to produce feed phosphate. The key technology is the purification of wet-process phosphoric acid, that is, the conten...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01B25/235C01B25/238C01B25/237C01B25/234

CPCC01B25/235C01B25/238C01B25/2375C01B25/2346C01P2006/80Y02P20/10

Inventor 周琼波牛司江赵智波刘正东符义忠朱德华李杰盆学彬坝吉贵杨雄俊陈玖毅

Owner YUNNAN PHOSPHATE CHEM GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com