A method for photocatalytic degradation of perfluorooctanoic acid in water by noble metal doped gallium oxide

A technology of perfluorooctanoic acid and gallium oxide, which is applied in the field of water treatment, can solve the problems of reduced photocatalytic efficiency, high recombination efficiency, ineffectiveness, etc., and achieves the effects of simple and easy operation, mild reaction conditions, and improved defluorination efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

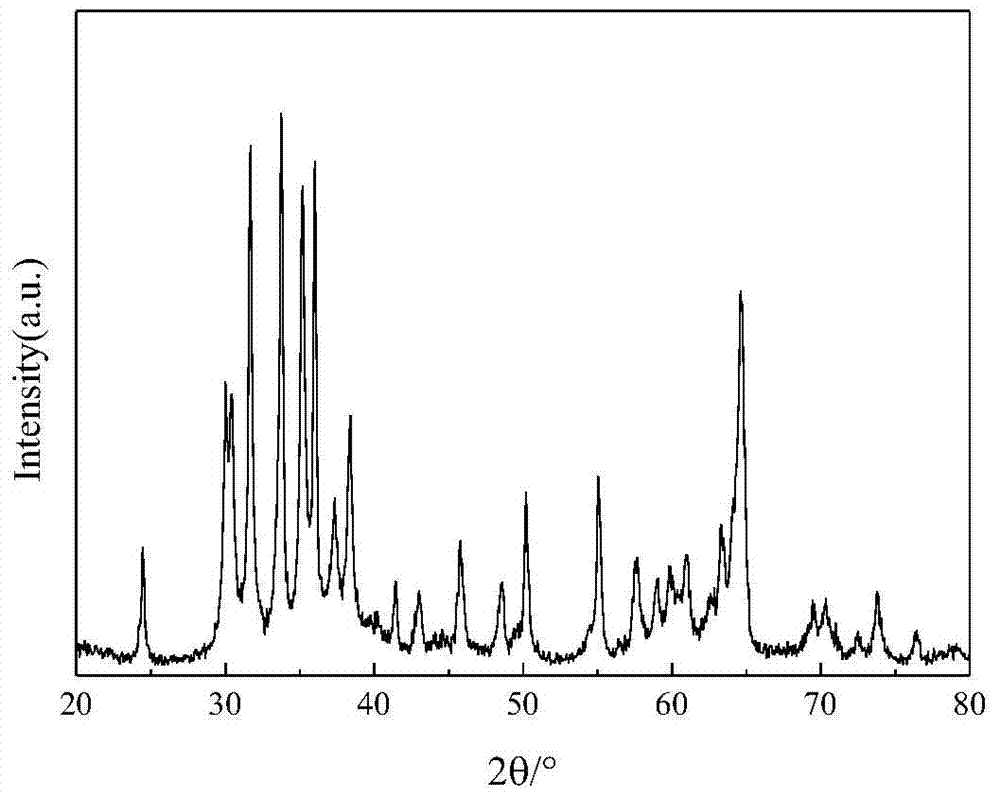

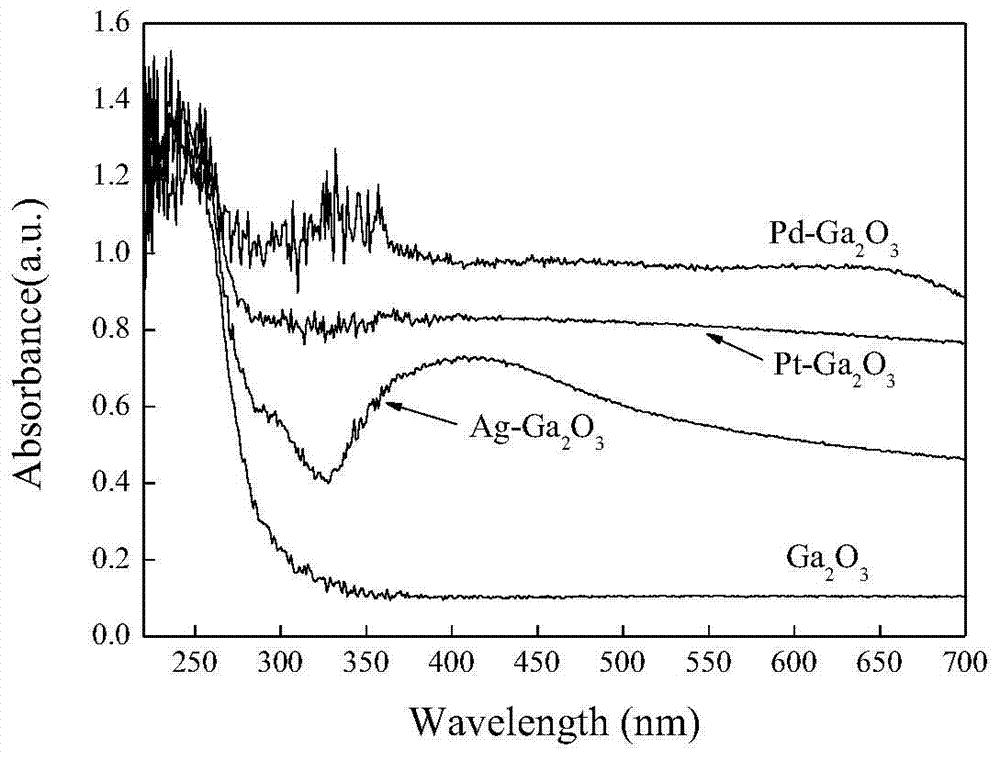

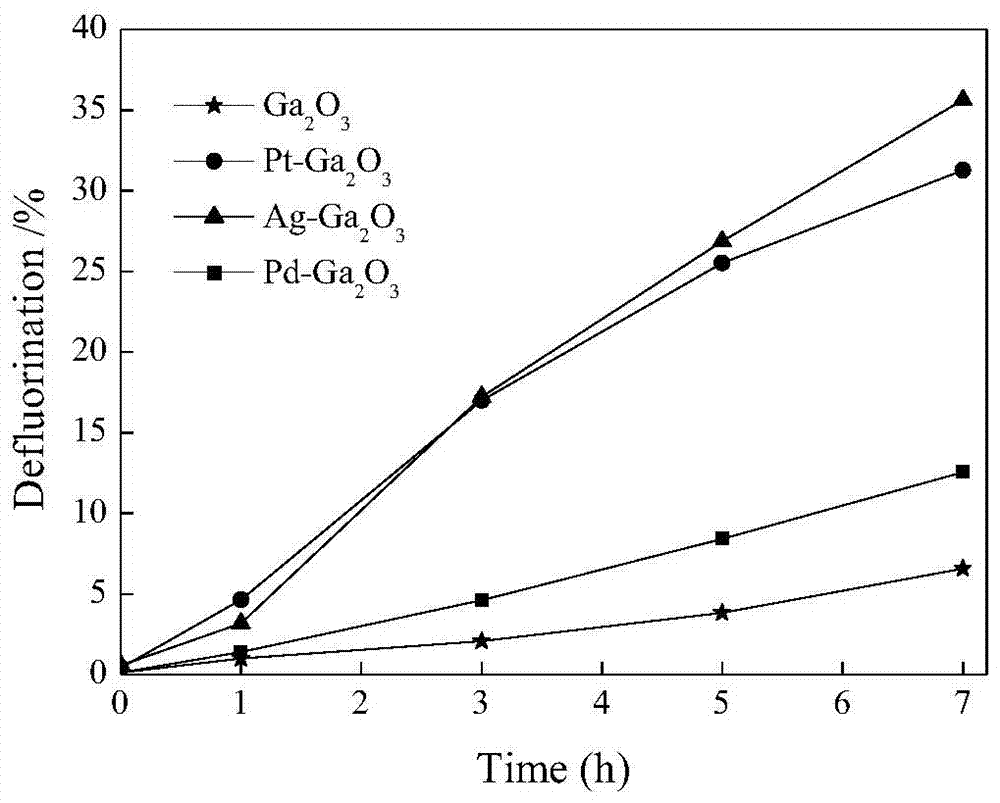

[0027] Example 1 : Platinum-doped gallium oxide (Pt-Ga 2 o 3 ) catalyst preparation and use of its photocatalytic degradation of perfluorooctanoic acid

[0028] Commodity gallium oxide (Ga 2 o 3 ) was dried at 105°C for 1h, and 0.5g of the dried Ga 2 o 3 Add deionized water into the beaker to form a 12.5g / L suspension, and ultrasonicate for 30min; add 3.1mL of chloroplatinic acid solution with a concentration of 0.02mol / L to the suspension, and stir for 1h; then add 2.5mL dropwise to a concentration of 0.5 mol / L potassium borohydride solution, continue to stir for 30 minutes to reduce metal platinum on the gallium oxide, filter the above mixed solution, and dry the precipitate at 105°C for 12 hours to obtain a doping amount of 1%. Pt-Ga 2 o 3 Photocatalyst, ready for use after grinding.

[0029] Measure 180mL of perfluorooctanoic acid solution with a concentration of 30mg / L in the photoreactor, add 0.09g of the above Pt-Ga 2 o 3 Catalyst, aerated with nitrogen, and...

Embodiment 2

[0031] Example 2: Palladium-doped gallium oxide (Pd-Ga 2 o 3 ) catalyst preparation and use of its photocatalytic degradation of perfluorooctanoic acid

[0032] Commodity gallium oxide (Ga 2 o 3 ) was dried at 105°C for 1h, and 0.5g of the dried Ga 2 o 3 Add deionized water into the beaker to form a 12.5g / L suspension, and ultrasonicate for 30min; add 0.6mL palladium chloride solution with a concentration of 0.1mol / L to the suspension, and stir for 1h; then add 2.5mL dropwise to a concentration of 0.5 mol / L potassium borohydride solution, continue to stir for 30 minutes, so that metal palladium is reduced and supported on gallium oxide, the above-mentioned mixed solution is suction-filtered, and the precipitate is dried at 105°C for 12 hours to obtain a doping amount of 1%. Pd-Ga 2 o 3 Photocatalyst, ready for use after grinding.

[0033] Measure 180mL of perfluorooctanoic acid solution with a concentration of 30mg / L in the photoreactor, add 0.09g of the above Pd-Ga ...

Embodiment 3

[0035] Example 3: Silver-doped gallium oxide (Ag-Ga 2 o 3 ) catalyst preparation and use of its photocatalytic degradation of perfluorooctanoic acid

[0036] Commodity gallium oxide (Ga 2 o 3 ) was dried at 105°C for 1h, and 0.5g of the dried Ga 2 o 3 Add deionized water into the beaker to make a suspension of 12.5g / L, ultrasonic for 30min; add 0.6mL silver nitrate solution with a concentration of 0.1mol / L to the suspension, stir for 1h; then add 2.5mL dropwise to a concentration of 0.5 mol / L potassium borohydride solution, continue to stir for 30 minutes, so that metallic silver is reduced and supported on gallium oxide, the above mixed solution is suction-filtered, and the precipitate is dried at 105°C for 12 hours to obtain Ag with a doping amount of 1%. -Ga 2 o 3 Photocatalyst, ready for use after grinding.

[0037] Measure 180mL of perfluorooctanoic acid solution with a concentration of 30mg / L in the photoreactor, add 0.09g of the above Ag-Ga 2 o 3 Catalyst, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com