Defluorination calcination device and technology for minerals containing lithium

A roasting device and defluorination technology, which is applied in the defluorination roasting device and the field of defluorination of fluorine-containing minerals, and can solve the problems of low energy utilization rate and large water vapor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

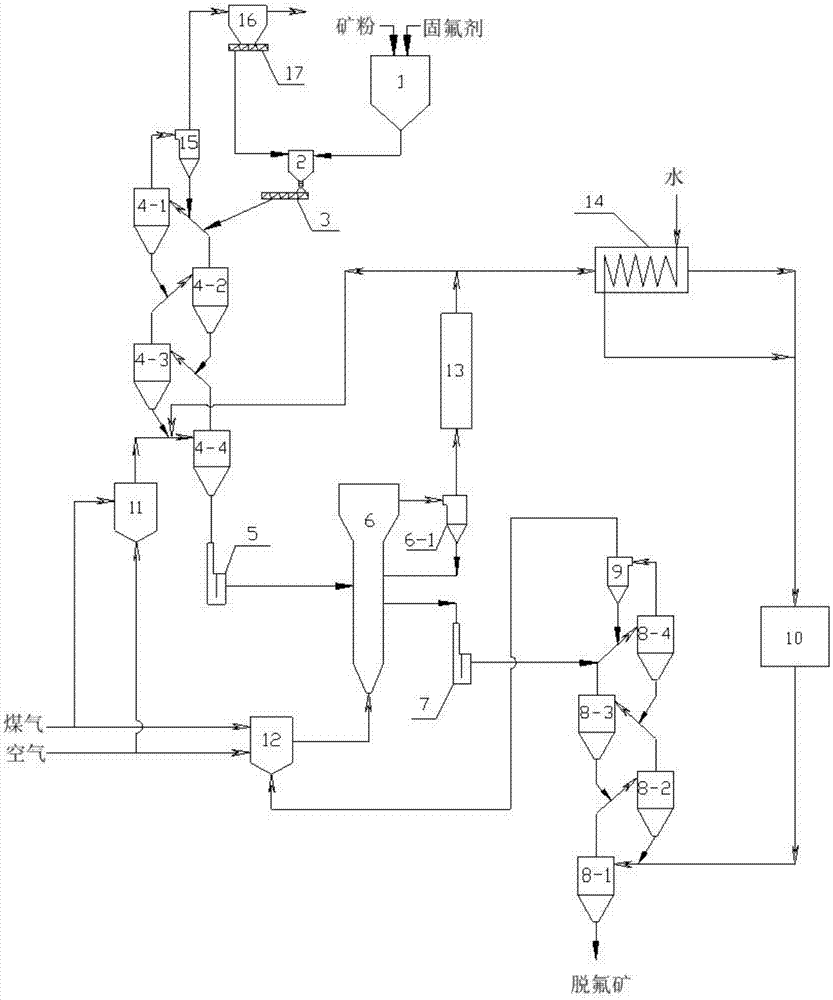

[0082] figure 1 Provides a schematic structural diagram of a lepidolite fluidized bed defluorination roasting device, the device includes: a feeding system, a mineral powder preheating system, a fluidized roasting system, a water vapor preheating system, a gas absorption system, and a cooling system and steam circulation system.

[0083] The feeding system is used to transport the materials to be defluorinated to the mineral powder preheating system, including raw material bin 1, hopper 2, and screw feeder 3;

[0084] The mineral powder preheating system is used to preheat the material to be defluorinated to a temperature of 800-850°C, including a combustion chamber 11, a four-stage cyclone preheater and a cyclone separator 15, and the four-stage cyclone preheater includes sequentially connected The first stage cyclone preheater 4-1, the second stage cyclone preheater 4-2, the third stage cyclone preheater 4-3 and the fourth stage cyclone preheater 4-4;

[0085] The fluidize...

Embodiment 2

[0104] Utilize the device that embodiment 1 provides to carry out lepidolite roasting defluorination, comprise the steps:

[0105] (1) Add lepidolite ore powder from the raw material bin 1 into the hopper 2, send it to the first-stage cyclone preheater 4-1 through the screw feeder 3, and pass through the second-stage cyclone preheater 4-2, The third-stage cyclone preheater 4-3 and the fourth-stage cyclone preheater 4-4 exchange heat with the high-temperature hot flue gas from the combustion chamber 11; at the same time, the steam boiler 14 and the hot blast stove 12 generate high-temperature steam ;

[0106] (2) The temperature of the preheated lepidolite ore powder rises to 800°C, and it is sent into the fluidized bed roaster 6, and fully contacts with the high-temperature water vapor (1000°C) from the hot blast stove 12 to carry out the roasting defluorination reaction, and the roasting The reaction conditions are: the fluidized bed roaster 6 is a 5-stage fluidized bed reac...

Embodiment 3

[0118] Utilize the device that embodiment 1 provides to carry out lepidolite roasting defluorination, comprise the steps:

[0119] (1) Add lepidolite ore powder from the raw material bin 1 into the hopper 2, send it to the first-stage cyclone preheater 4-1 through the screw feeder 3, and pass through the second-stage cyclone preheater 4-2, The third-stage cyclone preheater 4-3 and the fourth-stage cyclone preheater 4-4 exchange heat with the high-temperature hot flue gas from the combustion chamber 11; at the same time, the steam boiler 14 and the hot blast stove 12 generate high-temperature steam ;

[0120] (2) The temperature of the preheated lepidolite ore powder rises to 850°C, and is sent into the fluidized bed roaster 6, and fully contacts with the high-temperature water vapor (1000°C) from the hot blast stove 12 to carry out the roasting defluorination reaction, and the roasting The reaction conditions are: the fluidized bed roaster 6 is a three-stage fluidized bed rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com